Preparation method of mesoporous molecular sieve containing L zeolite secondary structural unit

A secondary structural unit, mesoporous molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of complex synthesis process, achieve large adjustable range, good diesel aromatics hydrogenation sulfur resistance and ring-opening performance , acidity and acidity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

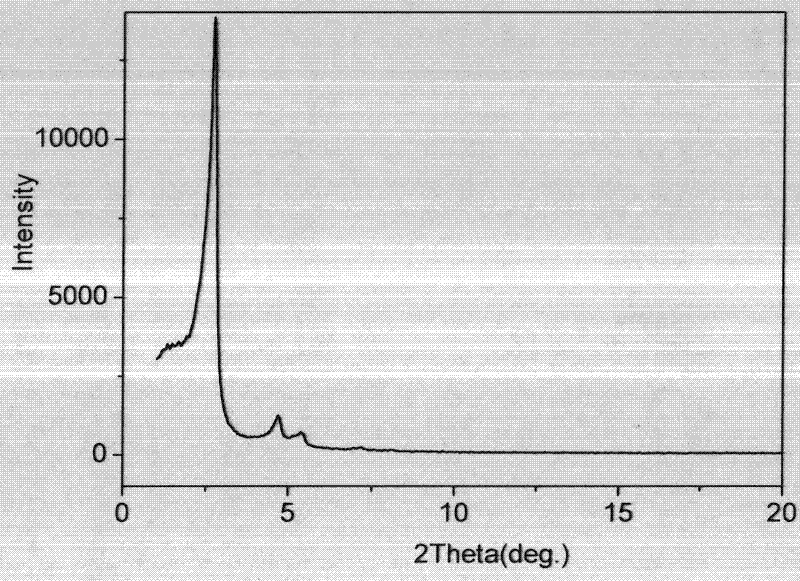

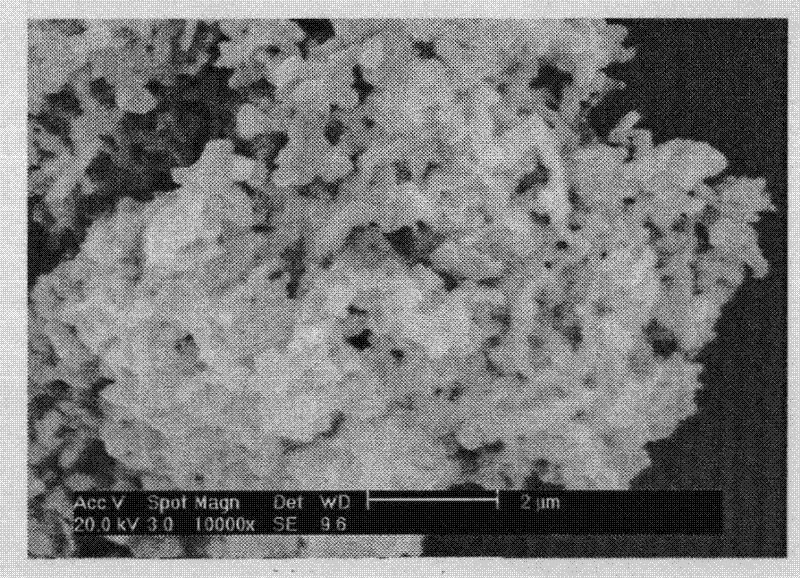

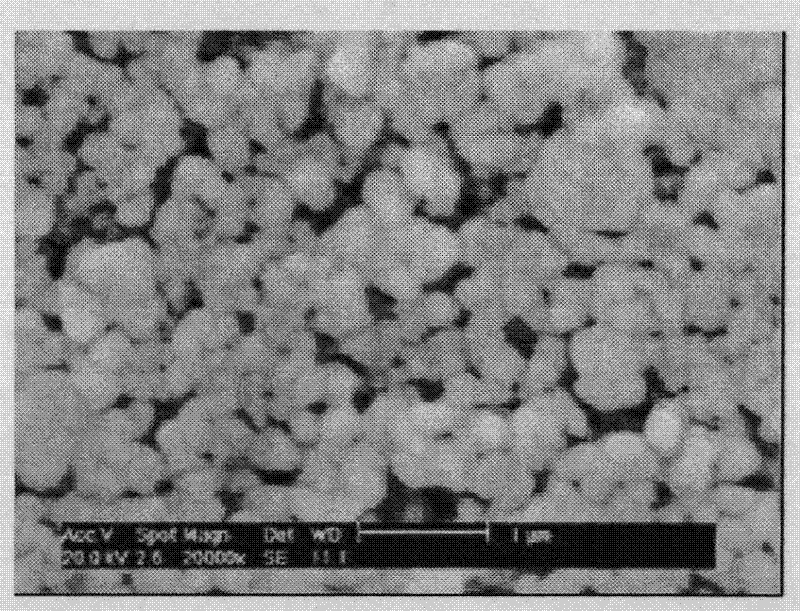

[0030] Industrial synthesis of NH 4 Exchanged NH 4 L(SiO 2 / Al 2 o 3 Molecular molar ratio is 10, the following are all SiO 2 / Al 2 o 3 All molecular molar ratios) zeolite 7.2g is dispersed in 200mL 4M HCl solution to form a hydrogel, after stirring at room temperature for 1h, put it into a synthesis kettle, place it at 120°C for 6h, and adjust the pH value to 13 with 6M NaOH after cooling About; then drop 16.5g of 16wt% cetyltrimethylammonium chloride solution into the hydrogel, stir at 50°C for 40min, and adjust the pH to about 10 with hydrochloric acid; stir evenly and put the material into the lining polytetrafluoroethylene crystallized at 110°C for 4 days; then filtered, washed, and dried at 100°C for 24 hours; and then calcined at 550°C for 8 hours in an air atmosphere to obtain the desired product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum (IR) analysis, the MCM-41 product framework cont...

Embodiment 2

[0032] Industrial synthesis of NH 4 Exchanged NH 4 L(SiO 2 / Al 2 o 3 Molecular molar ratio is 10, the following are all SiO 2 / Al 2 o 3 Both are molecular molar ratio) Zeolite 5.2g is dispersed in 200mL 4M H 2 SO 4In the solution, a hydrogel is formed. After stirring at room temperature for 1 hour, put it into a synthesis kettle, place it at 100°C for 12 hours, and adjust the pH value to about 13 with 6M NaOH after cooling; Drop ammonium chloride solution into the hydrogel, stir at 50°C for 40 minutes, add 8g of tetraethyl orthosilicate, and adjust the pH to about 10 with hydrochloric acid; stir evenly and put the materials into a crystallization kettle lined with polytetrafluoroethylene. Crystallize at 130°C for 3 days; then filter, wash, and dry at 100°C for 24 hours; then bake at 550°C for 8 hours in an air atmosphere to obtain the desired product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum...

Embodiment 3

[0034] Industrially synthesized pretreated L zeolite, SiO 2 / Al 2 o 3 =30, 12.2g dispersed in 300mL 0.5MHNO 3 In the solution, a hydrogel is formed, stirred at room temperature for 1h, put into a synthesis kettle, placed at 150°C for 3h, and adjusted to pH 13 with 6M NaOH; then 12.0g 16wt% cetyltrimethylammonium bromide Drop the solution into the hydrogel, stir at 50°C for 40min, and adjust the pH to about 10 with hydrochloric acid; after stirring evenly, put it into a crystallization kettle lined with polytetrafluoroethylene, and crystallize at 110°C for 3 days; then filter, wash, and dry at 100°C Dry at ℃ for 24h; then bake at 550℃ in air atmosphere for 8h to obtain the target product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to infrared spectrum (IR) analysis, the MCM-41 product framework contains L zeolite secondary structural units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com