Preparation method of highly stable MSUY-41 molecular sieve

A MSUY-41, high-stability technology, applied in the field of preparation of MSUY-41 molecular sieves, can solve the problems of high price of organic templates, narrow range of silicon-aluminum ratio, complex synthesis process, etc., and achieve good hydrothermal stability, reliable The effect of large tuning range and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Industrially synthesized NaY(SiO 2 / Al 2 o 3 The molecular molar ratio is 4.7, the following are all SiO 2 / Al 2 o 3 Both are molecular molar ratios) in the presence of water vapor, hydrothermal treatment at 0.2MPa and 500°C for 3 hours, and then treated with hydrochloric acid solution to obtain modified Y zeolite, SiO 2 / Al 2 o 3 =10.

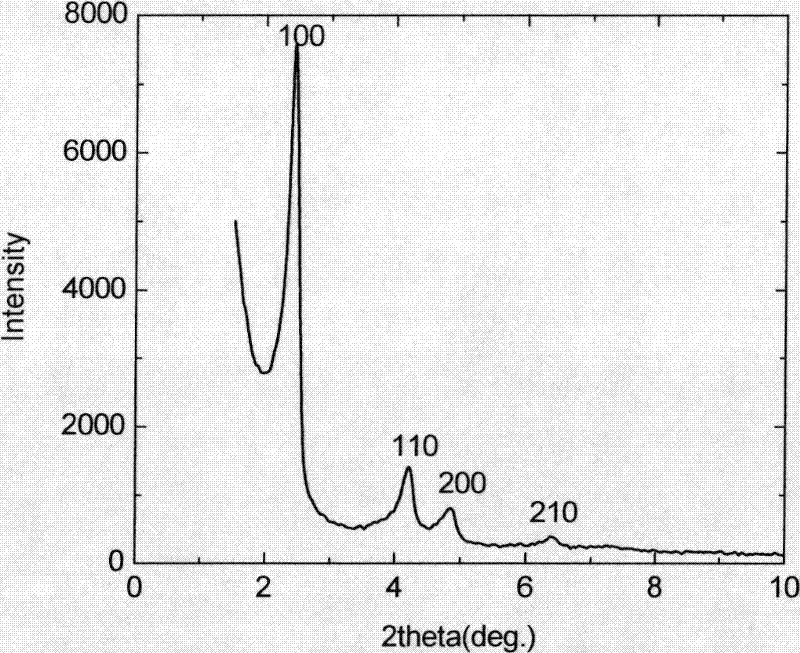

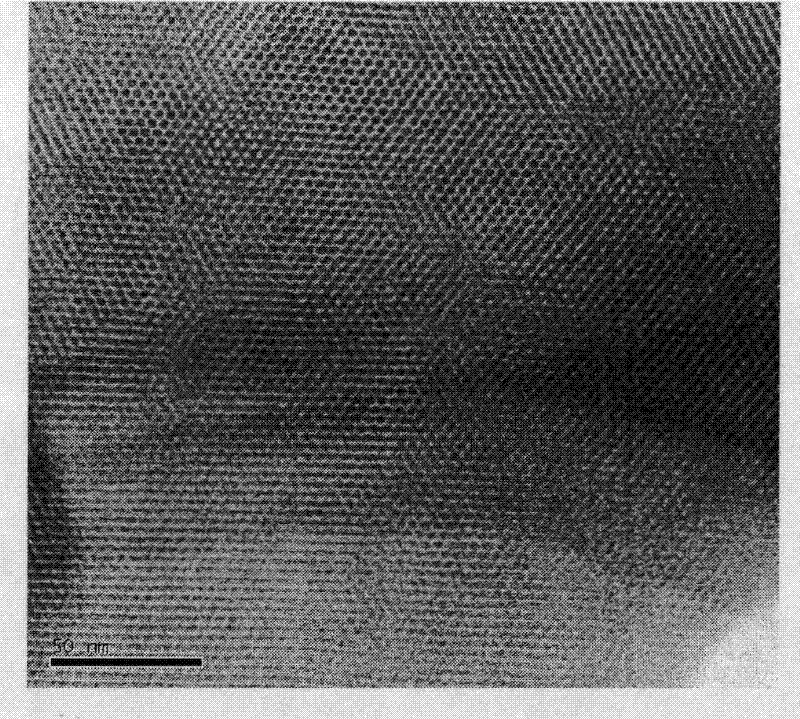

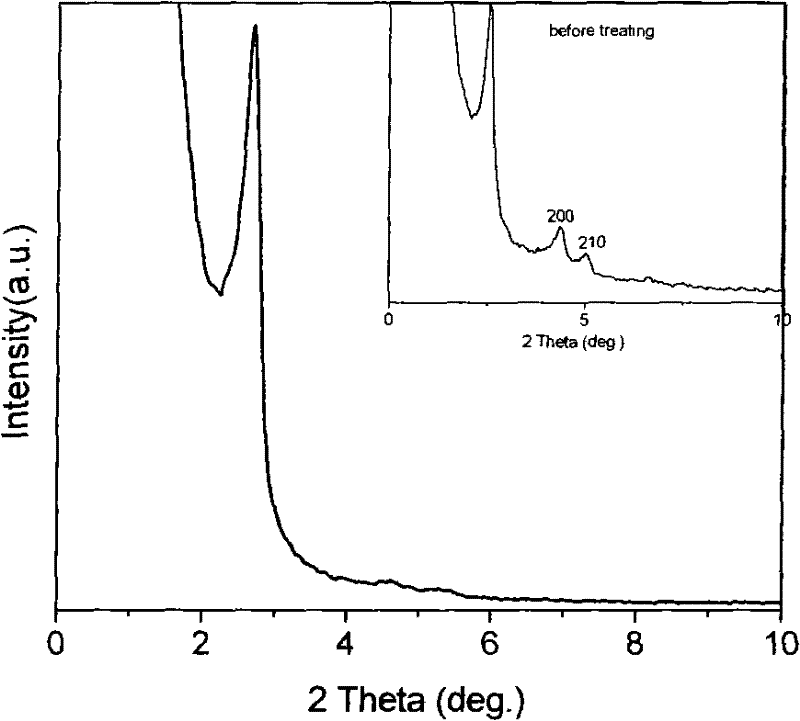

[0033] Disperse 4.8g of the above-mentioned modified Y zeolite in 50mL 2M HCl solution to form a hydrogel, stir at room temperature for 4h, and adjust the pH value to about 13 with 6M NaOH; then 12.5g of 16wt% cetyltrimethyl Drop the ammonium chloride solution into the hydrogel, stir at 50°C for 40 minutes, and adjust the pH to about 10 with hydrochloric acid; stir evenly, put the material into a crystallization kettle lined with polytetrafluoroethylene, and crystallize at 110°C for 2 days; then filter, Wash and dry at 100°C for 24h; then bake at 550°C for 8h in an air atmosphere to obtain the target product. The molecular siev...

Embodiment 2

[0035] Industrially synthesized NaY was hydrothermally treated in the presence of water vapor at a pressure of 0.2MPa and 500°C for 3 hours, and then treated with hydrochloric acid solution to obtain a modified Y zeolite, SiO 2 / Al 2 o 3 =10.

[0036] Disperse 4.8g of the above-mentioned modified Y zeolite in 50mL of 3M HCl solution to form a hydrogel, stir at room temperature for 4h, and adjust the pH to 13 with 6M NaOH; then 12.5g of 16wt% cetyltrimethyl Drop the ammonium bromide solution into the hydrogel, stir at 50°C for 40 minutes, then add 7g of tetraethyl orthosilicate, and adjust the pH to about 10 with hydrochloric acid; Crystallize at ℃ for 2d; then filter, wash, and dry at 100℃ for 24h; then bake at 550℃ for 8h in an air atmosphere to obtain the target product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to IR analysis, the framework contains Y zeolite secondary structural units.

Embodiment 3

[0038] Industrially synthesized NaY was hydrothermally treated in the presence of water vapor at a pressure of 0.3MPa and 600°C for 2 hours, and then treated with hydrochloric acid solution to obtain a modified Y zeolite, SiO 2 / Al 2 o 3 =20.

[0039] Disperse 4.8 g of the above modified Y zeolite in 50 mL of 1M HNO 3 In the solution, a hydrogel was formed, stirred at room temperature for 4h, and the pH value was adjusted to 13 with 6M NaOH; then 10.8g of 25wt% cetyltrimethylammonium chloride solution was dropped into the hydrogel at 0.86mL / min Stir at 50°C for 40 minutes, adjust the pH to about 10 with acetic acid; after stirring evenly, put the material into a polytetrafluoroethylene-lined crystallization kettle, and crystallize at 110°C for 3 days; then filter, wash, and dry at 100°C 24h; and then baked at 550°C for 8h under air atmosphere to obtain the target product. The molecular sieve sample whose crystal phase is MCM-41 was obtained by XRD analysis. According to I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com