Preparation method of 2, 3, 3, 3-tetrafluoropropene

A technology of tetrafluoropropylene and tetrafluoroethylene, applied in the chemical field, can solve the problems of only 13%, not suitable for industrialization, and less HFO-1234yf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of 2,3,3,3-tetrafluoropropene, which uses tetrafluoropropene and a compound of the general formula CHXYZ as raw materials, and reacts in the presence of a catalyst to prepare 2,3,3,3-tetrafluoropropene. The compound of general formula CHXYZ is CH 3 Cl, the synthetic route is as follows:

[0030] CF 2 = CF 2 +CH 3 Cl→CF 3 CF=CH 2 +HCl

[0031] 20g of ZnF is filled in a SUS316 stainless steel tubular reactor device with an inner diameter of 2cm and a length of 40cm 2 / C catalyst, first feed nitrogen for replacement, then heat the device with steam to 450°C, continue nitrogen replacement for a period of time, stop nitrogen, start feeding monochloromethane and tetrafluoroethylene gas, and keep the internal pressure of the device at 0.3Mpa , wherein the flow rate of monochloromethane is 50ml / min, the flow rate of tetrafluoroethylene gas is 25ml / min, the temperature of the reaction tube is maintained at 450°C, the mixed gas after the reaction is co...

Embodiment 2

[0033] The reactor used in Example 1 is adopted, and the raw materials and operation steps are the same as those in Example 1. The reaction device is heated to 500°C by steam, and the constant temperature condition is maintained. The mixed gas after the reaction is collected at the outlet of the reaction device, and its components are analyzed by gas chromatography. , and the results are listed in Table 1.

Embodiment 3-5

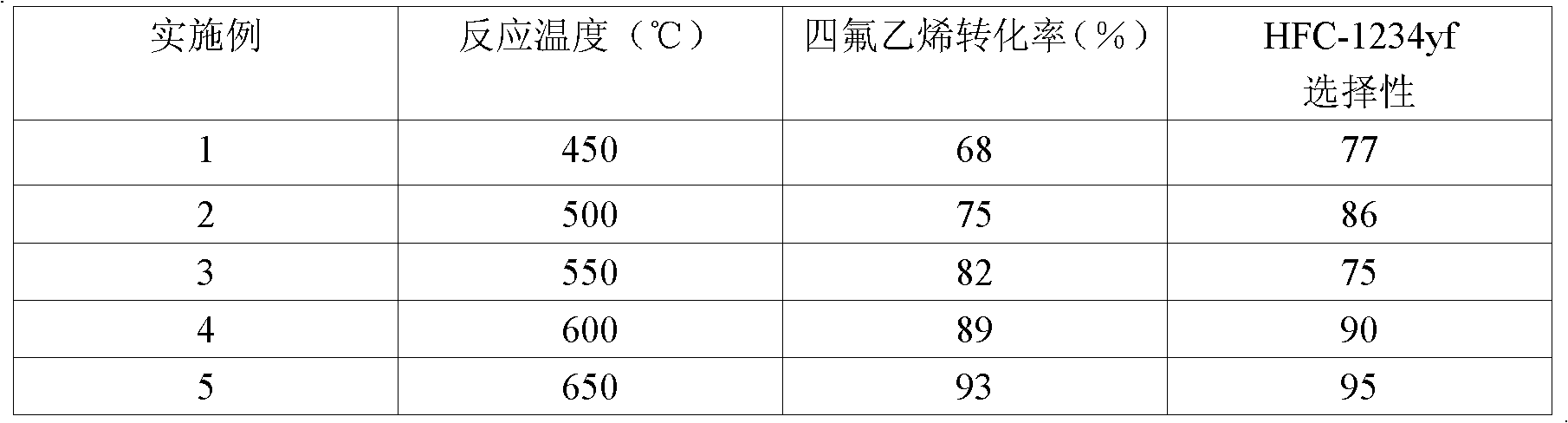

[0035] Using the reactor used in Example 1, the raw materials, catalysts, and operating steps are the same as in Example 1, except that the steam heating reaction device is respectively heated to 550°C, 600°C, and 650°C, and the corresponding temperature is kept at a constant temperature. The reacted mixed gas was collected at the outlet of the device, and its components were analyzed by gas chromatography, and the results are listed in Table 1.

[0036] Table 1: Its component of embodiment 3-5 gas chromatography analysis

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com