Low-volatility and low-mobility benzoyl formate

A free-radical and photo-initiator technology, which is used in the preparation of ester groups and hydroxyl groups, organic chemistry, etc. High efficiency, low volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dibutylene glycol dibenzoylformate

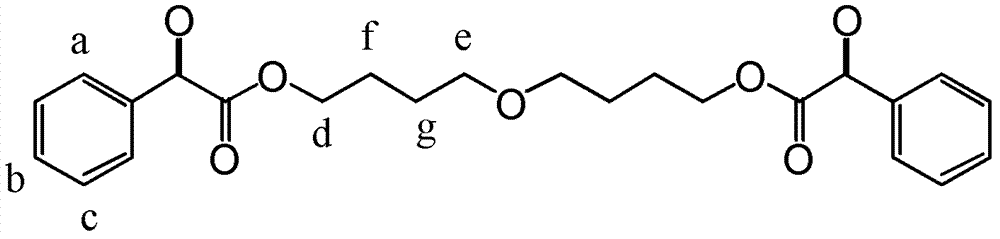

[0021] In a 500 ml four-neck flask, add 40.6 grams (0.25 moles) of dibutylene glycol, 82.5 grams (0.5 moles) of methyl benzoylformate and 4 g of sodium methoxide, heat up to 130 ° C and stir for 5 hours, while recovering Methanol. After cooling down, it was washed with water, and the water was evaporated under reduced pressure to obtain 104.5 g of a light yellow liquid product. High-pressure liquid chromatography analysis showed that the remaining content of methyl benzoylformate was 0.50%, the content of dibutylene diol dibenzoylformate was 98.5%, and the yield was 98%. Elemental analysis measured value (theoretical value), C: 67.28% (67.59%), H: 6.11% (6.14%). See Table 1 for H NMR spectrum data; see figure 1 .

[0022] Table 1-dibutylene glycol bisbenzoyl formate proton nuclear magnetic resonance spectrum data

[0023] serial number

[0024] g

Embodiment 2

[0026] In a 500 ml four-necked bottle, add 125.0 grams (0.5 moles) of polytetramethylene glycol 250 (containing 33% of dibutylene glycol, 38% of tributylene glycol, 22% of tetrabutylene glycol, and 4 6% pentabutylene glycol, 1% hexabutylene glycol), 165.0 g (1.0 mole) of methyl benzoylformate and 8 g of sodium methoxide, heated up to 130° C. and stirred for 8 hours, while recovering methanol. After cooling down, it was washed with water, and the water was evaporated under reduced pressure to obtain 251.3 g of a light yellow product. High-pressure liquid chromatography analysis showed that the remaining methyl benzoylformate content was 1.10%, the total content of all diesters was 98.15%, and the yield was 97.4%. The product liquid chromatography-mass spectrometry analysis results are shown in Table 2.

[0027] Table 2 Liquid chromatography-mass spectrometry analysis results

[0028]

Embodiment 3

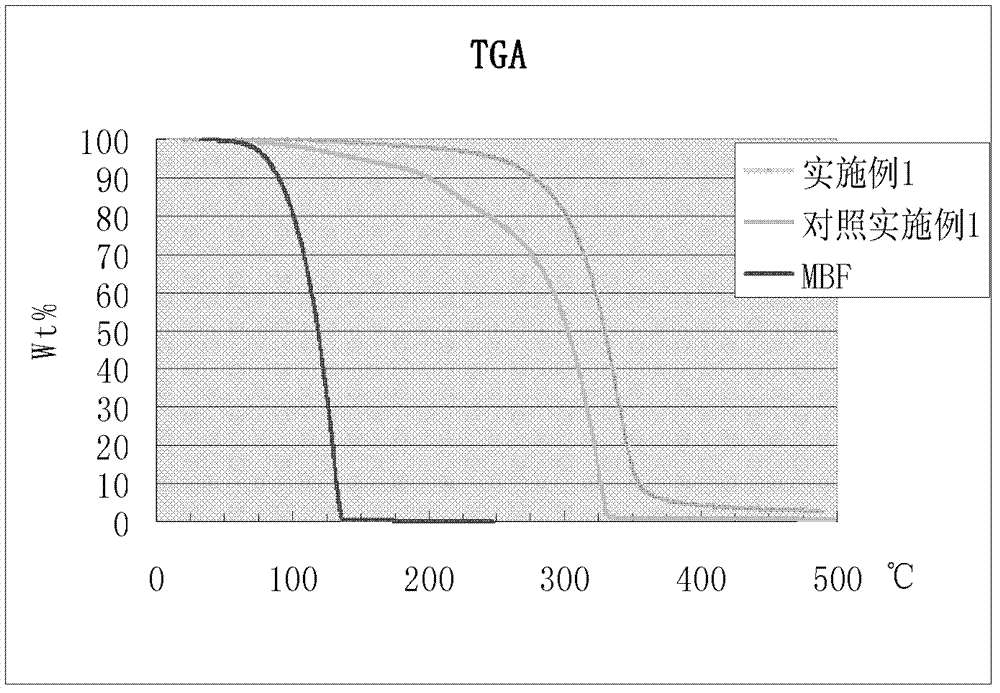

[0030] Thermogravimetric Analysis

[0031] Show that methyl benzoylformate (MBF) loses 50% at 120 ℃ with U.S. AT instrument company Q5000 thermogravimetric analysis data, promptly volatilizes completely at 140 ℃; Existing 22% weight loss, lose 50% when 300 ℃; And the sample 200 ℃ of embodiment 1 only loses 2%, 250 ℃ only lose 5% weight, lose 20% when 300 ℃, illustrate that the sample of embodiment 1 has significant Improved heat resistance and very low volatility. See the data graph figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com