Epoxy resin-based coating composition

A technology of epoxy resin coating and epoxy resin, applied in the direction of epoxy resin coating, polyamide coating, coating, etc., can solve the problems of irritating odor of curing assistant, complicated operation, etc., and achieve excellent curability and operability. Excellent, suitable service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

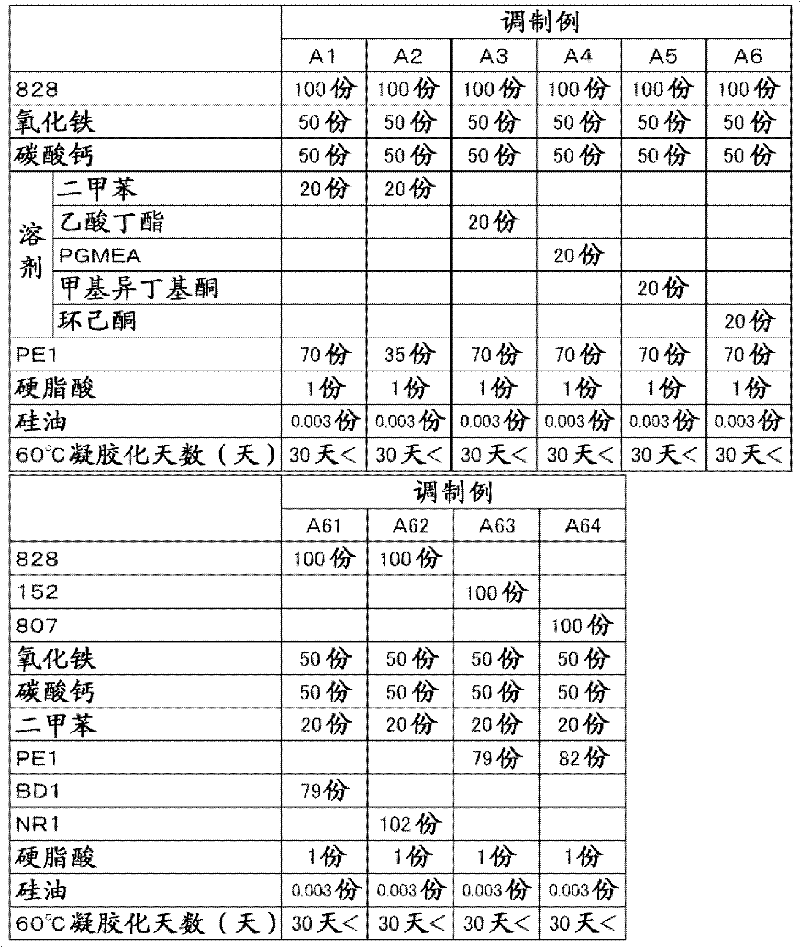

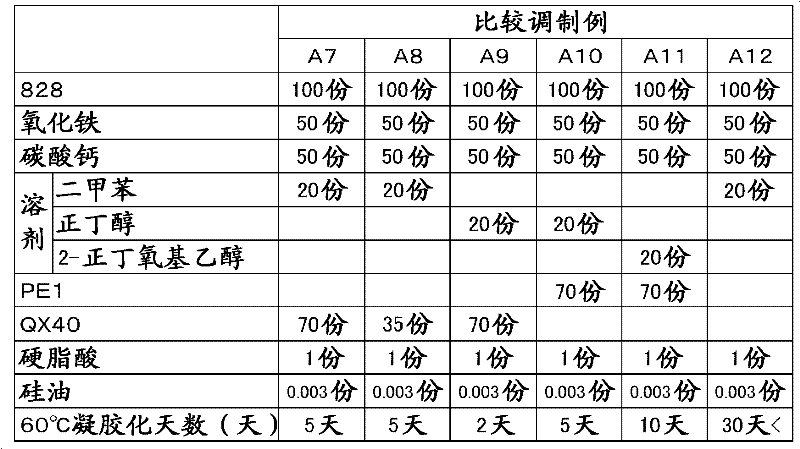

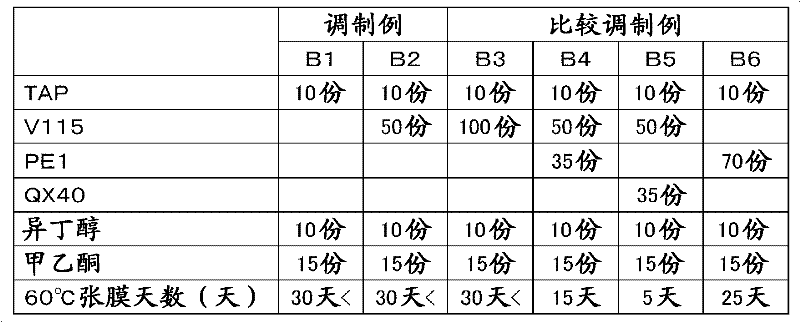

Method used

Image

Examples

Embodiment 1

[0141] Mix 30 parts of liquid A containing epoxy resin and compound (P) with a branched thiol group prepared in preparation example A1, and 4 parts of liquid B containing curing auxiliary agent prepared in preparation example B1 to obtain a ring Oxygen resin coating composition. This composition was coated on the polished steel plate using ANEST IWATA Co., Ltd. EASPRE-W-101. Adjust the air flow and valve opening during coating so that the film thickness after drying is about 30 microns. After coating, it was dried and cured at 25°C. As a result, it took 1 hour until the coating film was touched without leaving fingerprints (finger-touch drying time), and a good coating film was obtained.

Embodiment 2

[0143]Use A2 that has reduced the amount of the compound (P) with branched chain thiol groups in A liquid and 10 parts of B2 liquid that added polyamide amine curing agent in B liquid, in addition, by and embodiment 1 The same operation is carried out for coating, drying and curing. The dry-to-touch time was 4 hours, and a good coating film was obtained.

Embodiment 3~4

[0145] Coating, drying, and curing were performed in the same manner as in Examples 1 and 2, except that drying and curing were performed at 5°C. The dry-to-touch time was 5 to 10 hours, and it can be seen that it cured in a short time even at a low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com