Friction material composition, friction material obtained from same, and friction member

A friction material and composition technology, applied in the field of friction material composition and friction material, can solve problems such as insufficiency, achieve the effects of small aggressiveness, high friction coefficient, and inhibiting uneven wear of friction blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

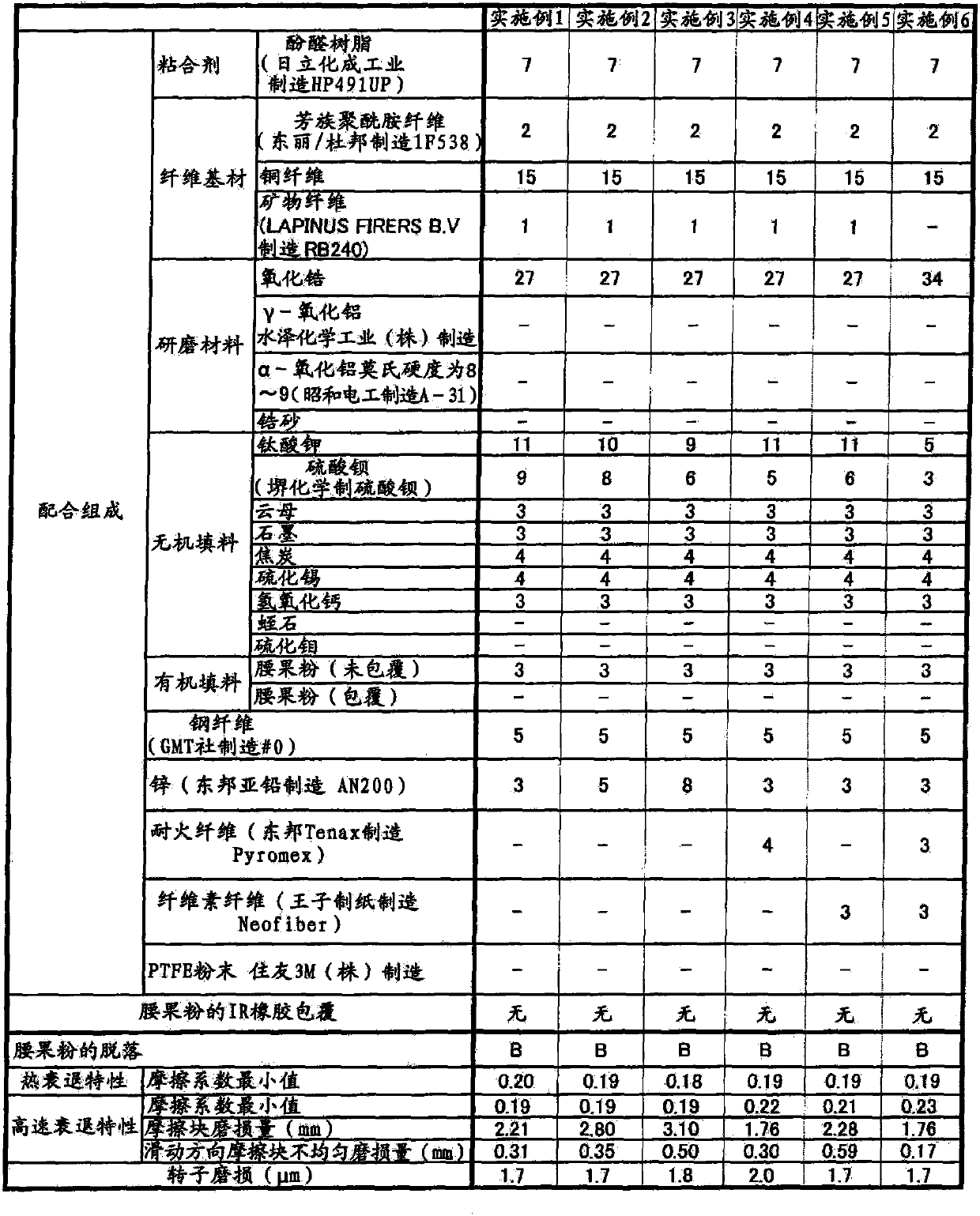

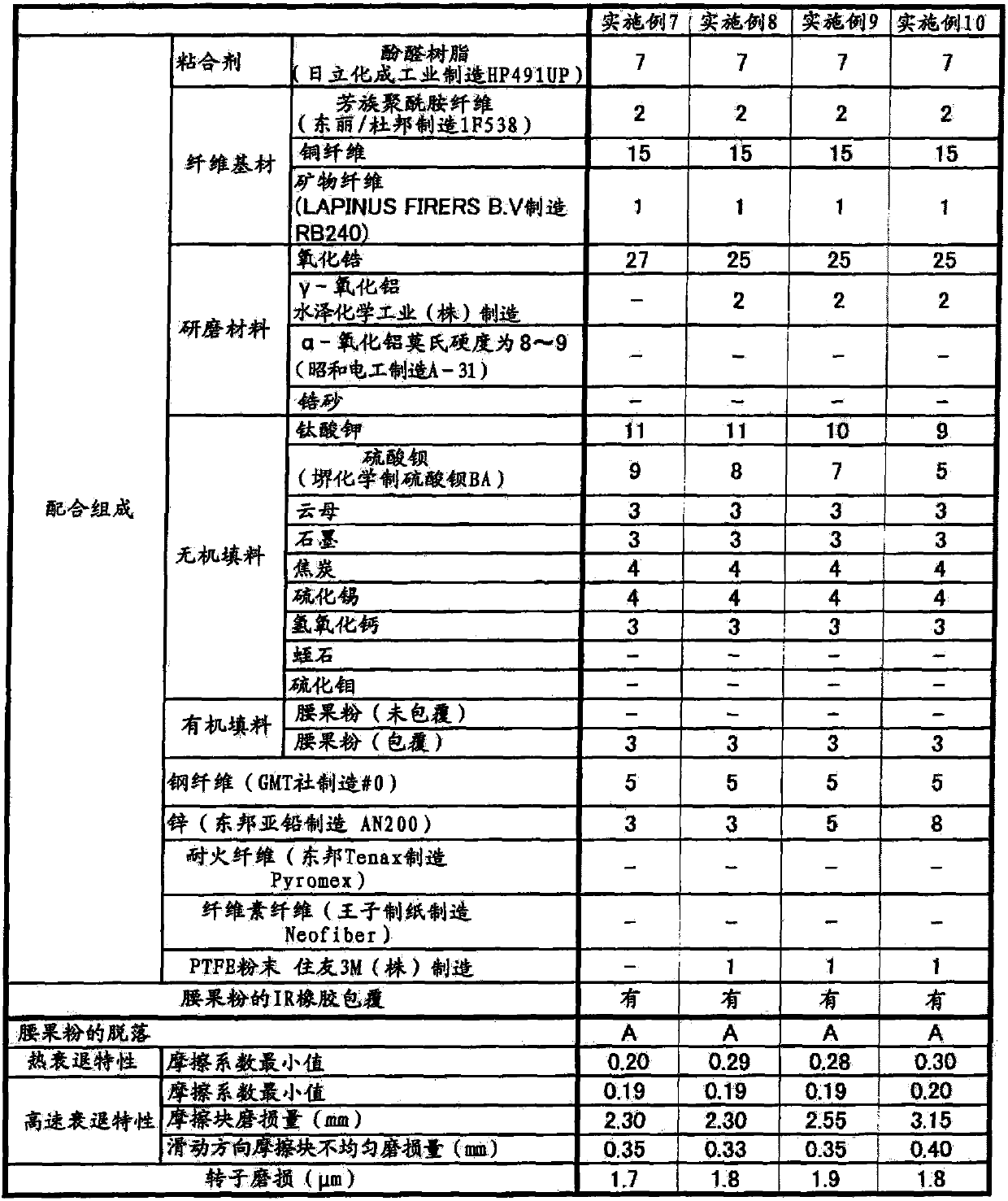

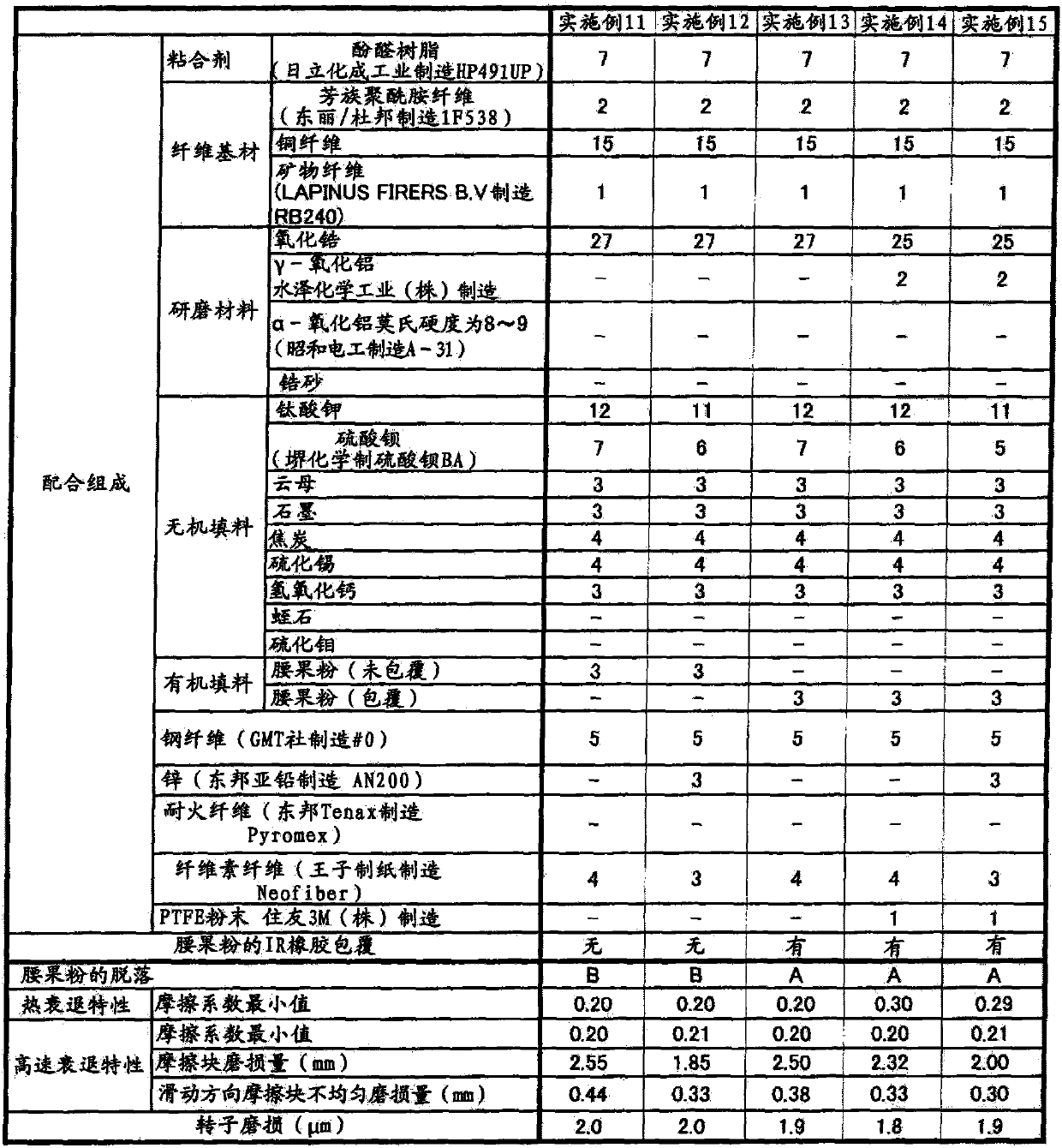

[0108] The friction material composition of the present invention will be further described using examples.

[0109] (Manufacturing of friction pads for disc brakes)

[0110] The materials were compounded according to the compounding ratios shown in Tables 1 to 5 to obtain the friction material compositions of Examples 1 to 20 and Comparative Examples 1 to 4.

[0111] In addition, the method of coating cashew powder with IR rubber is as follows. First, 100 parts by mass of cashew nut powder and 10 parts by mass of liquid IR rubber were pressurized and kneaded for 3 minutes under a pressure of 0.49 MPa using a pressurized kneader (manufactured by Moriyama Seisakusho Co., Ltd.).

[0112] The friction material composition was mixed using a Lodige mixer (manufactured by Matsubo Co., Ltd., trade name: Lodige mixer M20), the mixture was preformed using a molding press (manufactured by Oji Machinery Industry Co., Ltd.), and the mixture was preformed using a molding press ( Manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com