Preparation method for hollow ceramic ball with openings

A ceramic ball and hollow technology, which is applied in the field of preparation of hollow open-pore ceramic balls, can solve the problems of large bulk density, poor scale capacity, and small porosity, and achieve small bulk density, reduce bed pressure drop, and porosity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

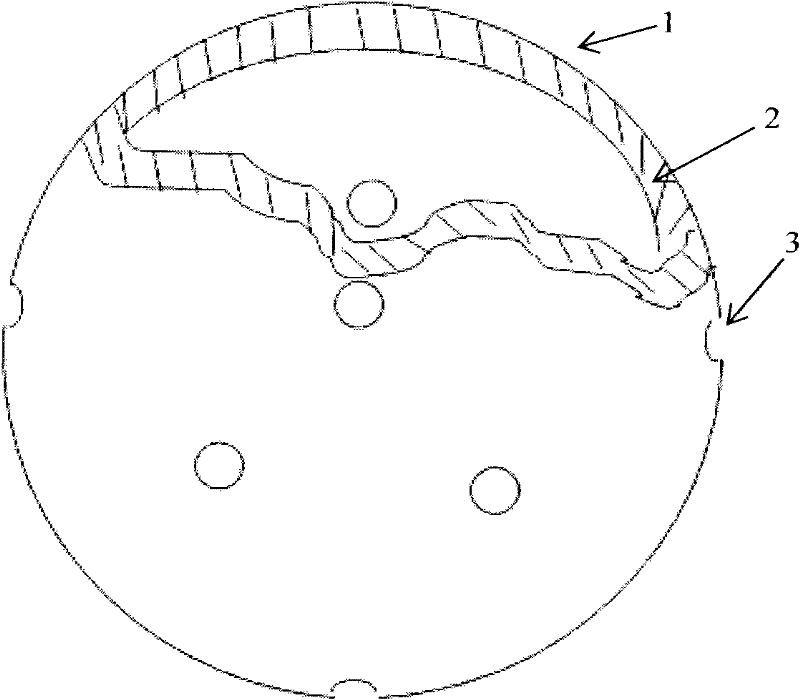

[0027] exist figure 1 Among them, the open-hole hollow ceramic ball is made of china clay, spherical activated carbon with a diameter of 14mm is used as a hollow agent, covered with 3mm thick porcelain clay, pressed into a spherical shape in a mold, and dried to form a porcelain embryo. Use a suitable tool to make round holes on the porcelain embryo. The diameter of the holes is 3 mm, and the number of holes is 10. The holes are evenly distributed on the spherical surface. Put the open-pored ceramic embryo into the roasting furnace, and gradually raise the temperature to 750°C under the introduction of air, so that the charcoal is converted into carbon dioxide and formed into a hollow ball. Continue to raise the temperature to 1400°C, sinter the hollow balls, then slowly cool down to 300°C, and accelerate cooling to room temperature to make hollow open-pore ceramic balls.

Embodiment 2

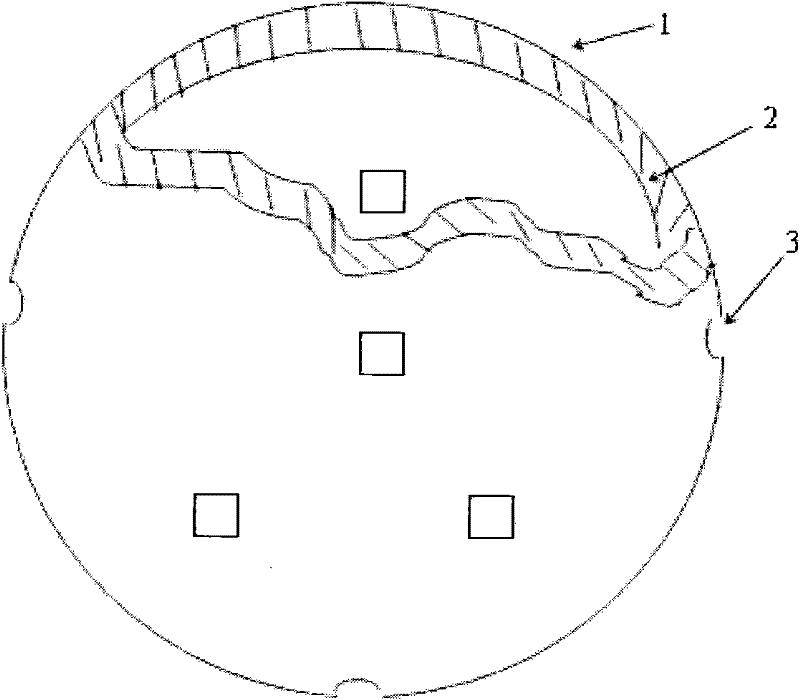

[0029] exist figure 2 Among them, the open-hole hollow ceramic ball is made of china clay, and spherical activated carbon with a diameter of 10 mm is used as a hollow agent, wrapped with 3 mm thick porcelain clay, pressed into a spherical shape in a mold, and dried to form a porcelain embryo. Use a special tool to open square holes on the porcelain embryo. The side length of the holes is 3mm, the number of holes is 10, and the holes are evenly distributed on the spherical surface. Put the open-pored ceramic embryo into the roasting furnace, and gradually raise the temperature to 600 ° C under the air, so that the charcoal is converted into carbon dioxide and formed into a hollow ball. Continue to raise the temperature to 1500°C, sinter the hollow balls, then slowly cool down to 300°C, and accelerate cooling to room temperature to make hollow open-pore ceramic balls.

Embodiment 3

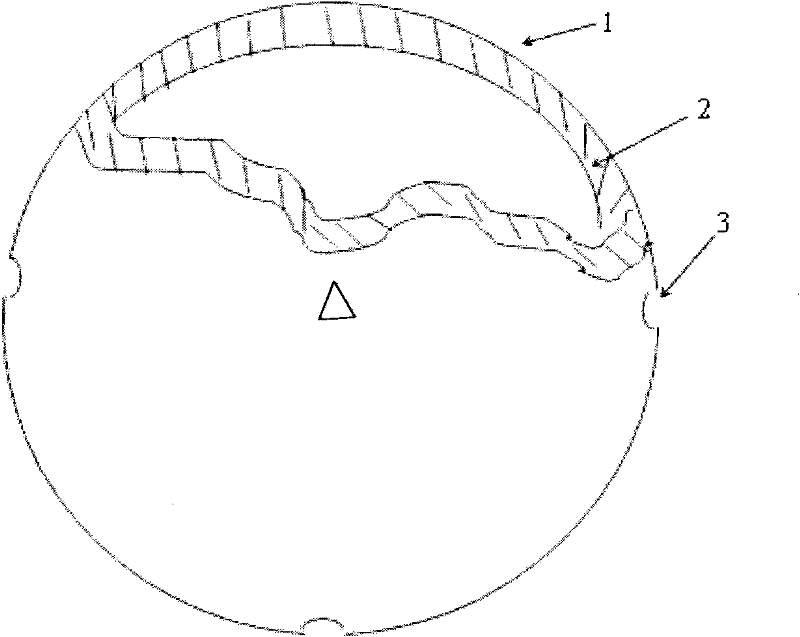

[0031] exist image 3 Among them, the open-hole hollow ceramic ball is made of china clay, spherical activated carbon with a diameter of 5mm is used as a hollow agent, covered with 1mm thick porcelain clay, pressed into a spherical shape in a mold, and dried to form a porcelain embryo. Use a suitable tool to make triangular holes on the porcelain embryo. The side length of the holes is 1mm, the number of holes is 6, and the holes are evenly distributed on the spherical surface. Put the porous ceramic embryo into the roasting furnace, and gradually raise the temperature to 700°C under the air, so that the charcoal is converted into carbon dioxide and formed into a hollow ball. Continue to heat up to 1600°C, sinter the hollow balls, then slowly cool down to 400°C, and accelerate cooling to room temperature to make hollow open-pore ceramic balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com