A kind of preparation method of macroporous silica gel carrier

A technology of large pore volume and silica gel, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of pore volume and small pore size, and achieve the effect of simple operation, low cost and broad market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

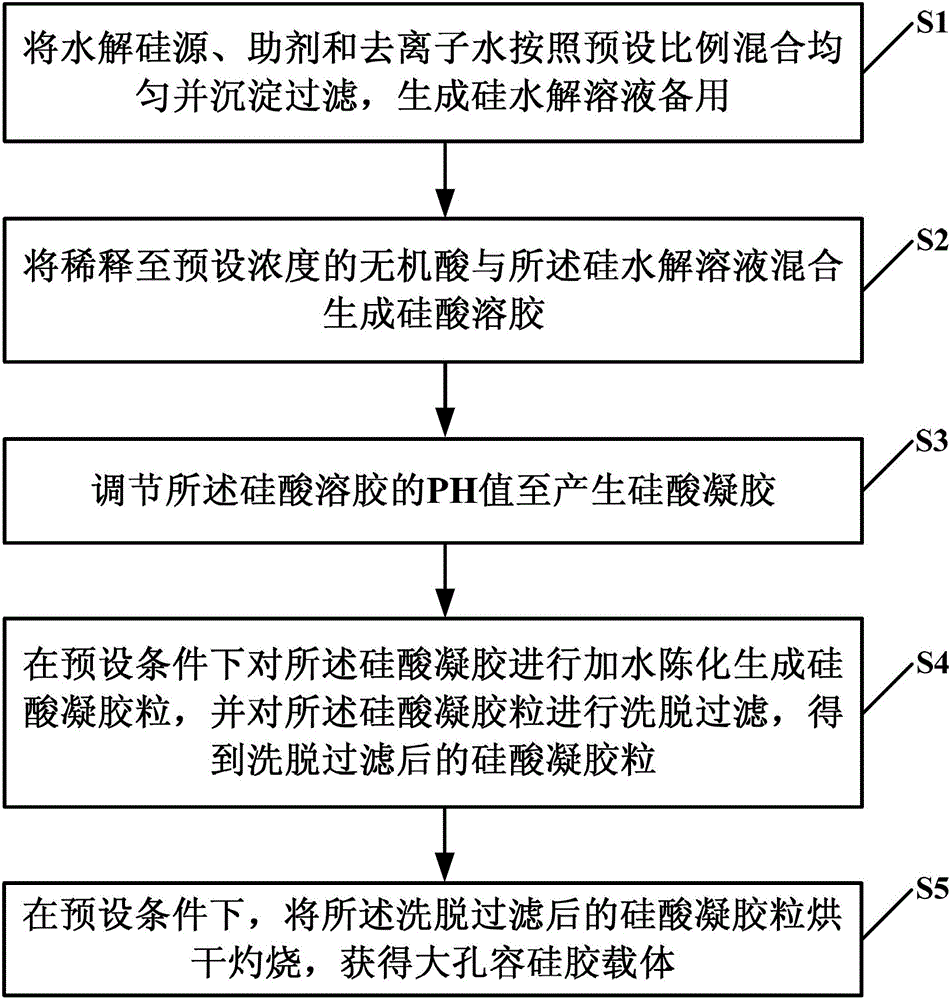

[0034] like figure 1 Shown, the preparation method of a kind of macroporous silica gel carrier of the present invention, comprises the following steps:

[0035] Mix the hydrolyzed silicon source, additives and deionized water according to the preset ratio evenly and precipitate and filter to generate a silicon hydrolyzed solution for later use;

[0036] mixing inorganic acid diluted to a predetermined concentration with the silicon hydrolysis solution to generate a silicic acid sol;

[0037] adjusting the pH value of the silicic acid sol to produce silicic acid gel;

[0038] Aging the silicic acid gel with water under preset conditions to generate silicic acid gel particles, and eluting and filtering the silicic acid gel particles to obtain eluted and filtered silicic acid gel particles;

[0039] Under preset conditions, the eluted and filtered silicic acid gel particles are dried and calcined to obtain a silica gel carrier with large pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com