Method for preparing biapenem by using micro-reaction technology

A biapenem and micro-reaction technology, which is applied in the field of preparing biapenem by using micro-reaction technology, can solve the problems of many by-products, low yield, long reaction time, etc., to prevent side reactions, increase specific surface area, The effect of reducing the amount of solvent used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

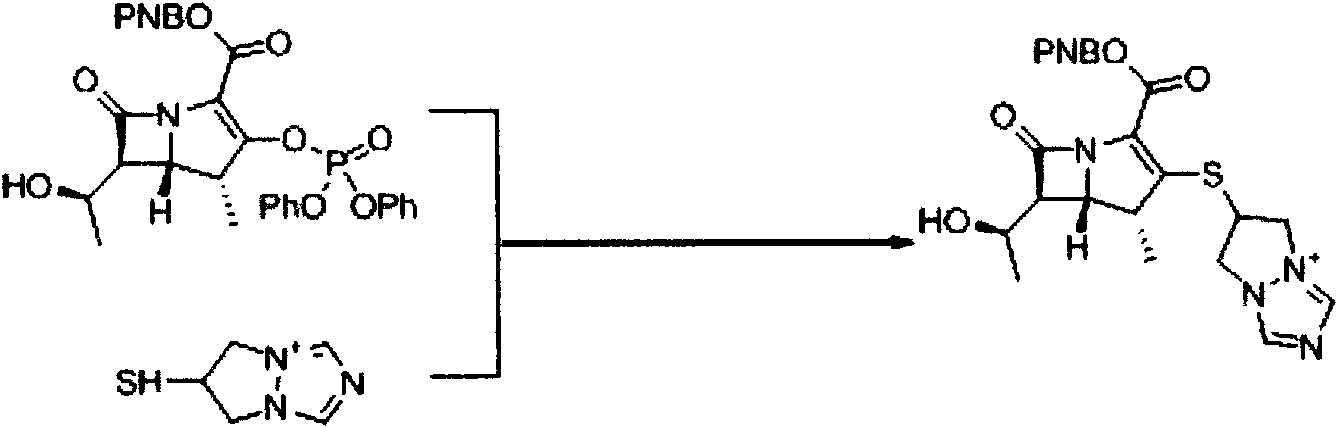

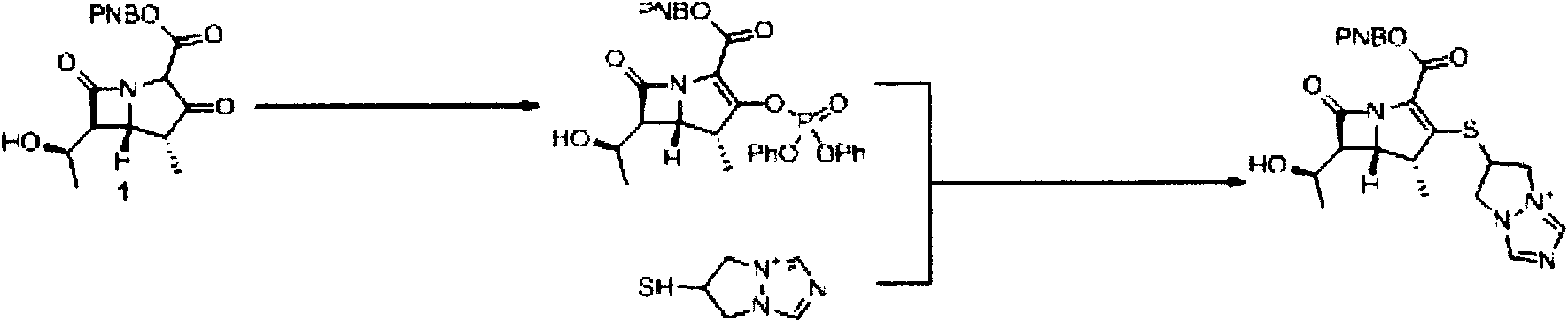

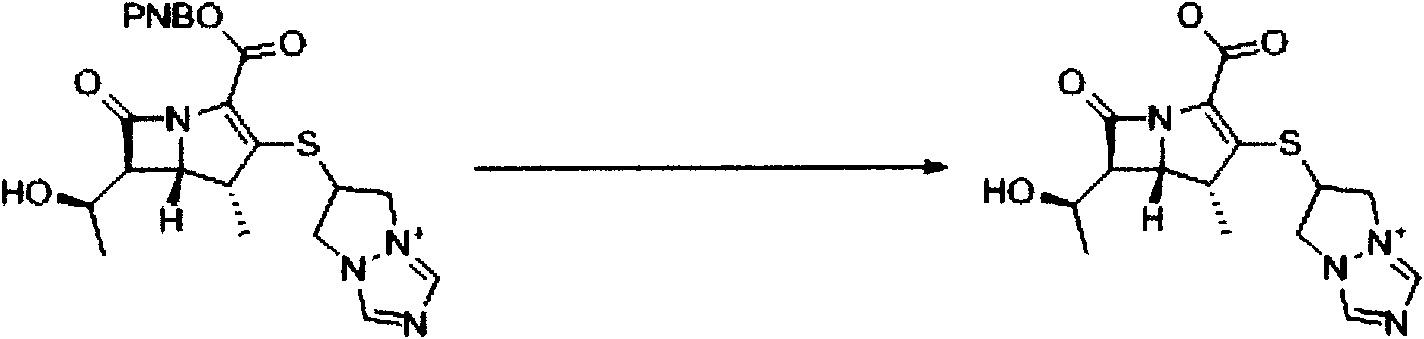

[0043] Synthesis of (4R, 5S, 6S)-3-[(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazolium-6-yl by microreaction technique )]-thio-6-[(R)-1-hydroxyethyl]-4-methylcarbapenicill-2-ene-2-p-nitrophenyl ester (1)

[0044] This reaction was carried out using a microchannel reaction system (FRX 100, Syrris). The first reserve part of the reaction system is loaded with 4.88g (8.0mmol) (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)-1-hydroxyethyl]-4-methyl carbon Penicillium-2-ene-2-p-nitrophenyl ester (2) and 30ml of anhydrous acetonitrile and slightly heated compound (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)- 1-Hydroxyethyl]-4-methylcarbapillin-2-en-2-p-nitrophenyl ester (2) was dissolved. The second storage portion of the reaction system was charged with 1.14 g (8.0 mmol) of 6-mercapto-(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazole ylide ( 3), 1.2ml (8.8mmol) diisopropylethylamine and 30ml anhydrous acetonitrile make it dissolve.Microchannel mixing part is the volume of reaction part is 1...

Embodiment 2

[0046] Synthesis of (4R, 5S, 6S)-3-[(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazolium-6-yl by microreaction technique )]-thio-6-[(R)-1-hydroxyethyl]-4-methylcarbapenicill-2-ene-2-p-nitrophenyl ester (1)

[0047] This reaction was carried out using a microchannel reaction system (FRX 100, Syrris). The first reserve part of the reaction system is loaded with 4.88g (8.0mmol) (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)-1-hydroxyethyl]-4-methyl carbon Penicillium-2-ene-2-p-nitrophenyl ester (2) and 30ml of anhydrous acetonitrile and slightly heated compound (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)- 1-Hydroxyethyl]-4-methylcarbapillin-2-en-2-p-nitrophenyl ester (2) was dissolved. The second storage portion of the reaction system was charged with 1.14 g (8.0 mmol) of 6-mercapto-(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazole ylide ( 3), 1.2ml (8.8mmol) diisopropylethylamine and 30ml anhydrous acetonitrile make it dissolve.Microchannel mixing part is the volume of reaction part is 1...

Embodiment 3

[0049] Synthesis of (4R, 5S, 6S)-3-[(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazolium-6-yl by microreaction technique )]-thio-6-[(R)-1-hydroxyethyl]-4-methylcarbapenicill-2-ene-2-p-nitrophenyl ester (1)

[0050] This reaction was carried out using a microchannel reaction system (FRX 100, Syrris). The first reserve part of the reaction system is loaded with 4.88g (8.0mmol) (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)-1-hydroxyethyl]-4-methyl carbon Penicillium-2-ene-2-p-nitrophenyl ester (2) and 30ml of anhydrous acetonitrile and slightly heated compound (4R, 5S, 6S)-3-diphenylphosphate oxy-6-[(R)- 1-Hydroxyethyl]-4-methylcarbapillin-2-en-2-p-nitrophenyl ester (2) was dissolved. The second storage portion of the reaction system was charged with 1.14 g (8.0 mmol) of 6-mercapto-(6,7-dihydro-5H-pyrazol[1,2-a][1,2,4]triazole ylide ( 3), 1.2ml (8.8mmol) diisopropylethylamine and 30ml anhydrous acetonitrile make it dissolve.Microchannel mixing part is the volume of reaction part is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com