Acidic visco-elastic fluid, its preparation method and application thereof

A viscoelastic and fluid technology, applied in the field of acid viscoelastic fluid and its preparation, can solve the problems of reducing formation permeability, incomplete gel breaking, residual microgel, etc., and achieves decontamination, seepage resistance, and good sand-carrying performance. , the effect of low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Prepare Agent A

[0049] Get 70g of eicosyltrimethylammonium chloride, 25g of methanol, and 5g of acetic acid. Thoroughly stir and dissolve the above substances, prepare a clear and transparent solution, and prepare Agent A with a viscosity of 10mPa·s.

[0050] (2) Preparation of agent B

[0051] Take 24g of cetyltrimethylammonium bromide, 15g of methanol, 36g of salicylic acid, and 10g of sodium hydroxide. Add the above substances into 15ml of water successively under stirring condition, fully stir and dissolve to form a reddish-brown clear liquid, and prepare agent B with a viscosity of 8mPa·s.

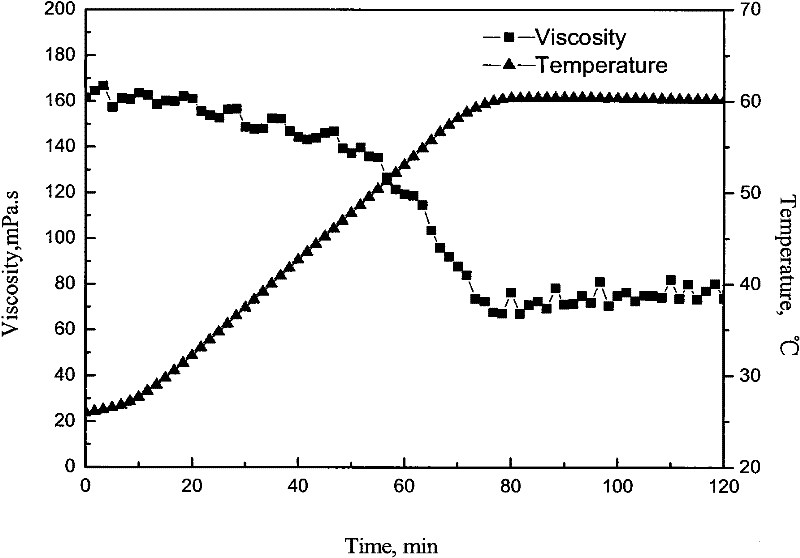

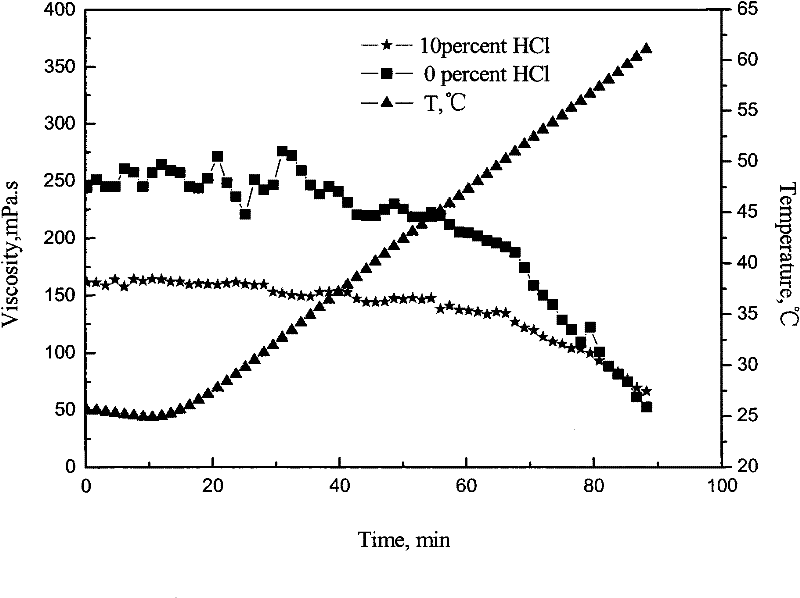

[0052] (3) Preparation of viscoelastic fluid

[0053] Take 24ml of analytically pure hydrochloric acid and dissolve 3g of KCL in 100ml of water. After fully dissolving, add a certain amount of corrosion inhibitor, add 6ml of agent A under stirring, and then add 1ml of agent B. The formed viscoelastic fluid has a viscosity of 160mPa·s, has good viscoelasticity and sand...

Embodiment 2

[0055] (1) Prepare Agent A

[0056] Take 70g of octadecyltrimethylammonium chloride, 17g of methanol, 8g of isopropanol, and 5g of acetic acid. Fully stir and dissolve the above substances, and prepare a clear and transparent solution with a viscosity of 8mPa·s Agent A.

[0057] (2) Preparation of Agent B

[0058] Get 24g of cetyltrimethylammonium chloride, 15g of methanol, 36g of salicylic acid, and 10g of sodium hydroxide. Add the above substances into 15ml of water sequentially under stirring condition, fully stir and dissolve to form reddish-brown clear liquid, agent B with a viscosity of 8mPa·s.

[0059] (3) Preparation of viscoelastic fluid

[0060] Take 24ml of analytically pure hydrochloric acid and dissolve 3g of KCL in 100ml of water. After fully dissolving, add a certain amount of corrosion inhibitor, add 6ml of agent A under stirring, and then add 1ml of agent B. The formed viscoelastic fluid has a viscosity of 165mPa·s, has good viscoelasticity and sand-carryi...

Embodiment 3

[0062] (1) Prepare Agent A

[0063] Get 70g of rapeseed oil-trimethylammonium chloride, 17g of methanol, and 8g of isopropanol. Fully stir and dissolve the above substances, and prepare a clear and transparent solution, A agent with a viscosity of 12mPa·s.

[0064] (2) Preparation of Agent B

[0065] Take 24g of tetradecyltrimethylammonium chloride, 15g of methanol, 36g of salicylic acid, and 10g of sodium hydroxide. Add the above substances into 15ml of water sequentially under stirring condition, fully stir and dissolve to form reddish-brown clear liquid, agent B with a viscosity of 8mPa·s.

[0066] (3) Preparation of viscoelastic fluid

[0067] Take 24ml of analytically pure hydrochloric acid and dissolve 3g of KCL in 100ml of water. After fully dissolving, add a certain amount of corrosion inhibitor, add 6ml of agent A under stirring, and then add 1ml of agent B. The formed viscoelastic fluid has a viscosity of 170mPa·s, has good viscoelasticity and sand-carrying perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com