Method for preparing osmium membrane through electroplating

A technology of osmium film and electroplating solution, which is applied in the field of preparing osmium film by electroplating method, which can solve the problems that the osmium film is prone to cracking and difficult to meet the requirements of use, and achieve the effect of prolonging the detection life, increasing the working life and not being easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

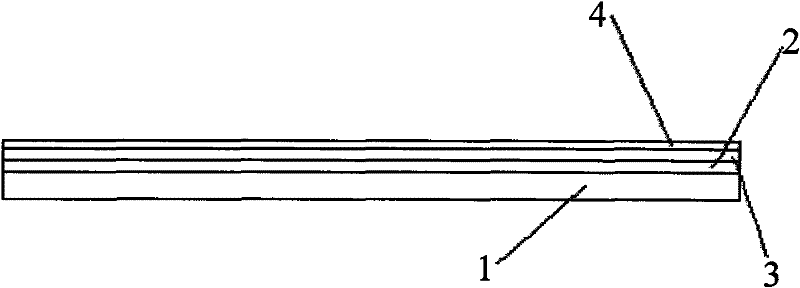

[0018] The osmium film of the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

[0019] The osmium film of the present invention is made by electroplating, its thickness can reach more than 1 micron, and it is not easy to crack. Wherein, the osmium film of the present invention takes a glass substrate as the substrate 1, and a chromium layer 2 is vacuum evaporated on the substrate 1. The thermal expansion coefficient of osmium and quartz is large, so the chromium film with a small thermal expansion coefficient is selected as the bottom layer to increase The bonding strength between the resistive film and the quartz substrate is very necessary. At the same time, due to the low conductivity of chromium, it is difficult to provide the current intensity required for electroplating. Therefore, it is necessary to deposit a layer with high conductivity and good chemical stability on the chromium film. A gold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com