Method for reducing germanium/silicon epitaxy surface defects

A silicon germanium epitaxy and silicon wafer surface technology, which is applied to chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problems of epitaxial layer crystal defects, quality reduction and poor effect of germanium silicon epitaxial growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

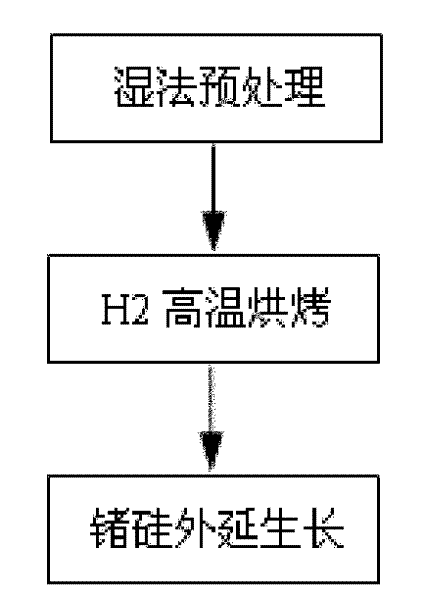

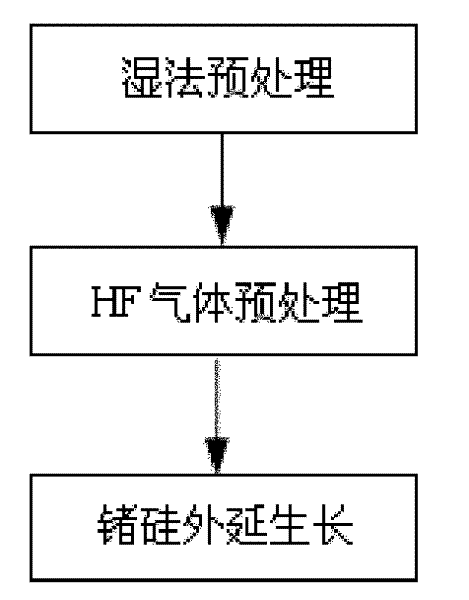

[0021] combine figure 2 Shown, in the present embodiment, the implementation process of the method of the present invention is as follows:

[0022] In the first step, the oxide layer and pollutants on the surface of the silicon wafer are removed by wet pretreatment.

[0023] In the second step, the silicon wafer is transported to the silicon germanium process chamber, and the surface of the silicon wafer is treated with HF gas under a certain temperature and pressure before the growth of silicon germanium. The function of HF gas treatment is to remove the natural oxide layer on the surface of the silicon wafer, the temperature during treatment is 100-800°C, and the pressure is 0.01-760Torr. In this embodiment, for example, the temperature is 400° C. and the pressure is 20 torr.

[0024] The third step is to adjust the process parameters and carry out epitaxial growth of silicon germanium on the surface of the silicon wafer. The parameters of germanium-silicon epitaxial gro...

Embodiment 2

[0026] combine figure 2 Shown, the method implementation process of the present invention is as follows:

[0027] In the first step, the oxide layer and pollutants on the surface of the silicon wafer are removed by wet pretreatment;

[0028] The second step is to transfer the silicon wafer to the silicon germanium process machine, first enter the HF pretreatment chamber, and in a vacuum or inert gas state (does not react with silicon), under a certain temperature and pressure, in the silicon germanium epitaxy Before the growth, the surface of the silicon wafer is treated with HF gas, for example, the temperature is 400° C., and the pressure is 20 torr. Then the silicon wafer is transferred to the silicon germanium process chamber, and the transfer process is in a vacuum state or an inert gas state (does not react with silicon).

[0029] The third step is to adjust the process parameters and carry out epitaxial growth of silicon germanium. The parameters of silicon germaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com