Preparation method for superabsorbent antibacterial fiber

A technology of water absorption and fiber, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of low release rate, cytotoxicity, poor thermal stability, etc., and achieve the effect of good water absorption, good antibacterial property and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

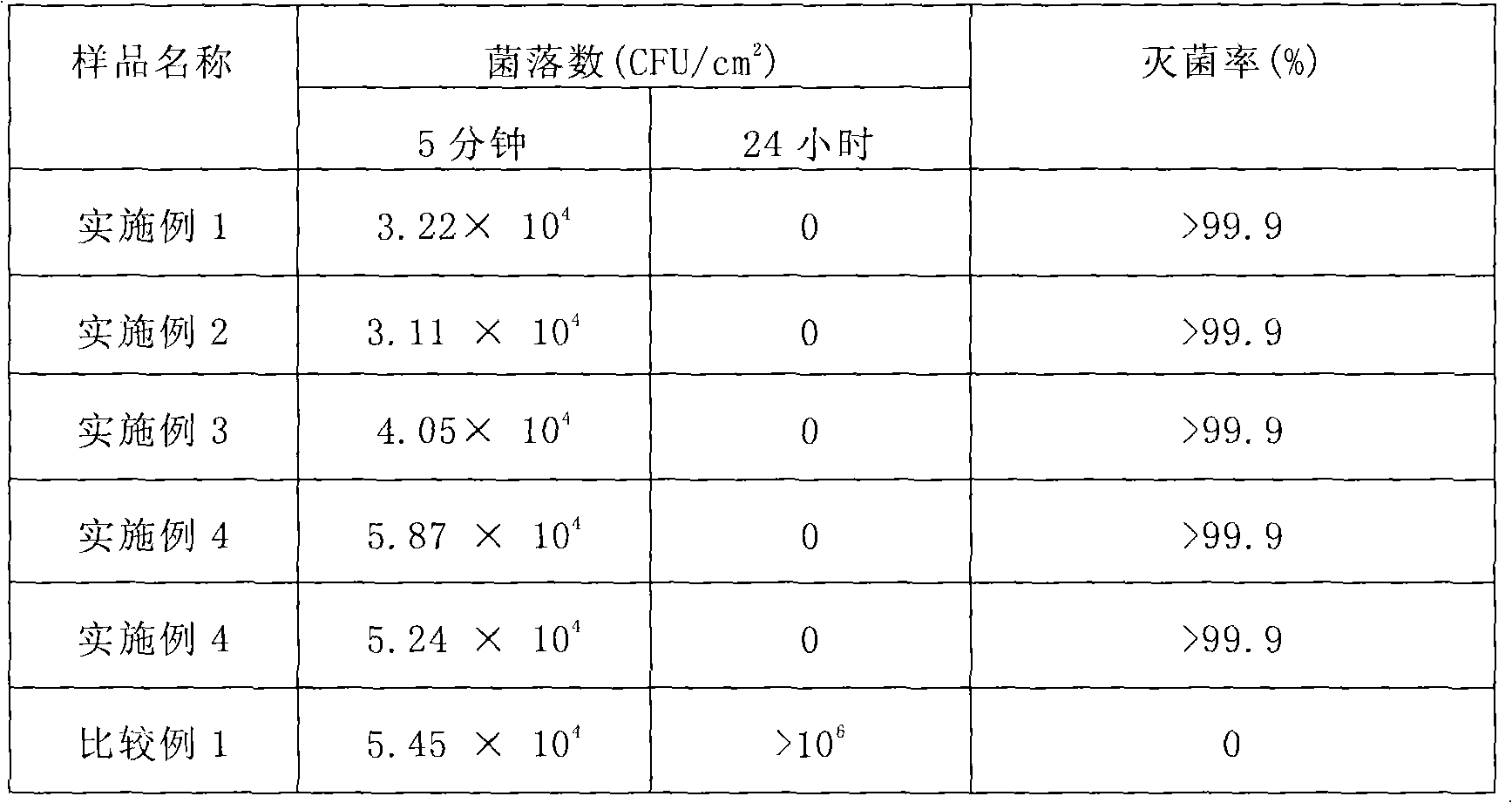

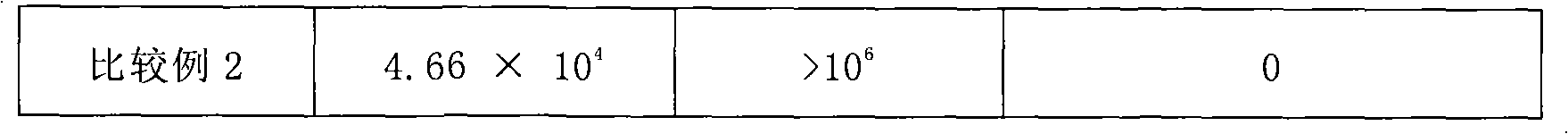

Examples

preparation example Construction

[0026] In order to make the preparation method of the present invention have a better preparation effect, the pH value of the aforementioned sodium hypochlorite aqueous solution is preferably in the range of 6-8; when the pH value is too high in an alkaline environment, it is easy to cause polyglutamic acid fibers. The reaction speed with sodium hypochlorite in sodium hypochlorite aqueous solution is slow, the degree of oxidation is poor and the effect is not good; when the pH is lower than 6, the reaction speed will increase, but at the same time, it will cause the breakage of the peptide bond (amide bond) and the decrease of the molecular weight, and the destruction The structure of polyglutamate fibers.

[0027] In order to control the pH value of the aforementioned sodium hypochlorite aqueous solution to be kept within a desired range during the reaction process, it is preferable to further add a pH value buffer to the sodium hypochlorite aqueous solution to adjust the pH v...

Embodiment 1

[0038] The polyglutamic acid fibers were soaked in a sodium hypochlorite aqueous solution with a concentration of 0.4 wt %, and the pH value was adjusted between 6-8 with a 0.5 N phosphoric acid aqueous solution, and the fibers were soaked for 40 seconds and taken out. The fibers were rinsed twice with water and left to dry.

Embodiment 2

[0040] The polyglutamic acid fibers were soaked in a sodium hypochlorite aqueous solution with a concentration of 0.3 wt %, and the pH value was adjusted between 6-8 with a 0.5 N phosphoric acid aqueous solution, and then taken out after soaking for 1 minute. The fibers were rinsed twice with water and left to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com