Method for testing high-voltage power supply and power distribution system loop

A technology for power supply and distribution system and loop testing, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of destroying high-voltage equipment, error-prone wiring, and increased workload, etc., and achieves simple testing devices and testing methods. Ease of use and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] 1. Preconditions: All installation work of the power distribution system, wiring and wiring, high-voltage relay protection, and insulation test are completed, and there is no other construction work on the power distribution system before power is received.

[0039] 2. Operation steps:

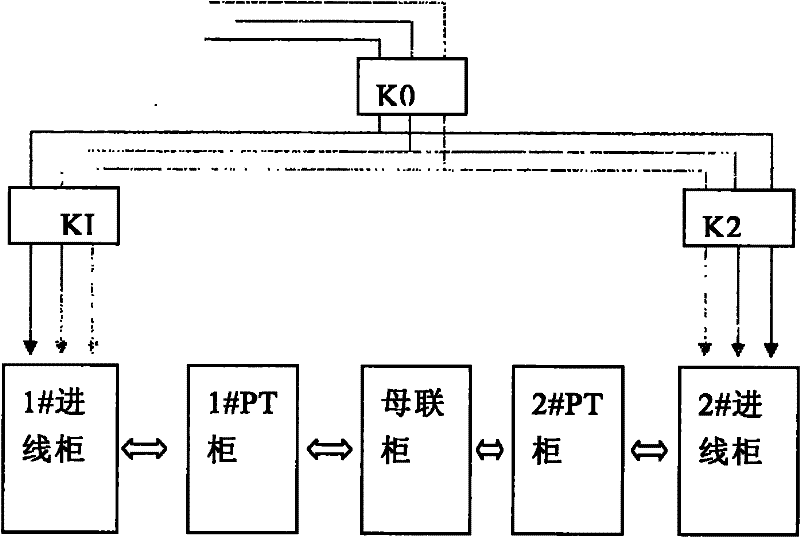

[0040] 1) Push the circuit breaker of the two-way incoming line cabinet to the working position; push the PT cabinet of the two sections of bus to the working position; push the bus tie lifting cabinet to the working position; pull the bus tie cabinet circuit breaker out of the cabinet, The upper and lower high-voltage contact baffles in the bus coupler cabinet are opened to expose the metal contacts.

[0041] 2) Press figure 1 Wiring shown: where K0, K1, K2 are three-phase air switches, A, B, C are three-phase 380V temporary test power supply.

[0042] 3) Measure the voltage value and phase sequence of the temporary power supply at K0, and ensure that the test power supply is in posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com