Film solar cell

A solar cell and thin film technology, applied in the field of solar cells, can solve the problems of reducing conversion efficiency, affecting the performance of solar cells, affecting the open-circuit voltage and short-circuit current of solar cells, etc., so as to achieve the effect of super confinement of light intensity and improvement of photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

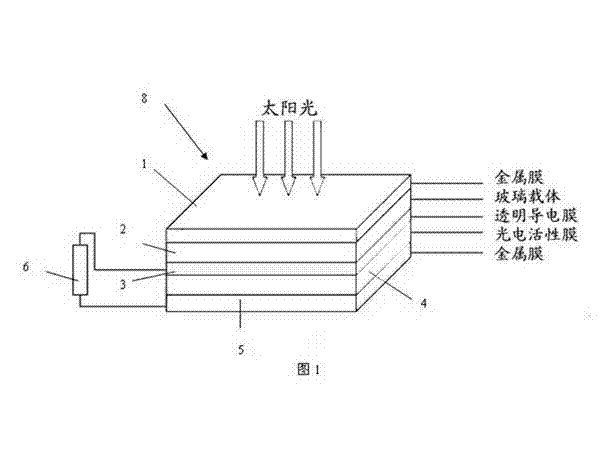

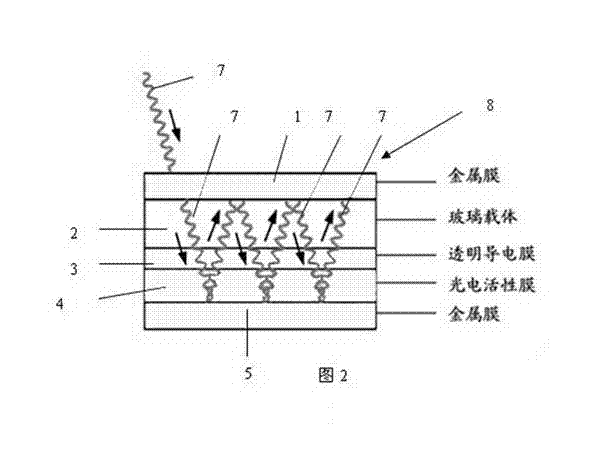

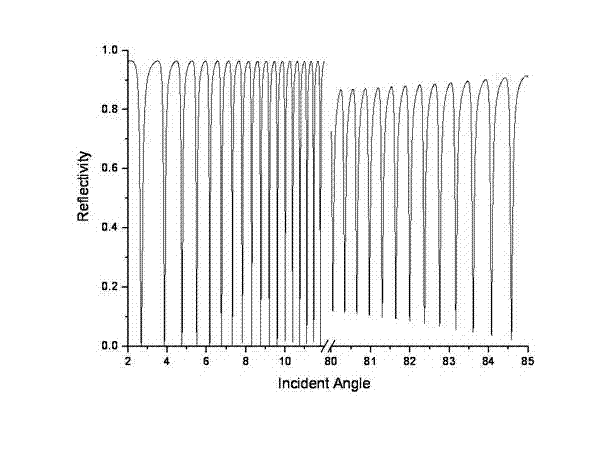

[0026] The present invention will be further described in detail by the accompanying drawings and examples below. A thin-film solar cell (8) is provided with an upper layer metal film (1), thick glass (2), transparent conductive film (3), photoactive Thin film (4) and lower metal film (5), wherein the upper metal film (1) and the lower metal film (5) form the cladding layer of the waveguide, thick glass (2), transparent conductive film (3) and photoelectric active film ( 4) Forming a waveguide layer, the lower metal film (5) and the transparent conductive film (3) constitute the electrodes of the battery, and the thickness of the upper metal film (1) is determined according to the wavelength band of the photoelectrically active film (4) with high photoresponsivity.

[0027] The thickness of the upper metal thin film (1) is determined by the wavelength band with a large photoresponsivity of the photoelectric active film (4).

[0028] The photoelectric active film (4) is a polyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com