Latex for dip molding, composition for dip molding, preparation method of dip molded product, and dip molded product prepared thereby

A dip molding and latex technology, which is applied in applications, household components, household appliances, etc., can solve the problems of reduced effective effect of stability, serious air bubbles, and poor quality of dipped molded products, and achieves excellent tensile strength, The effect of resolving inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

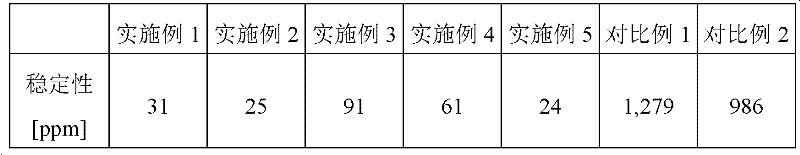

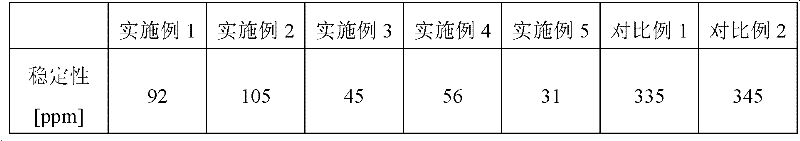

Examples

Embodiment 1

[0068] 1-1. Preparation of latex for dip molding

[0069] A 10L high-pressure reactor connected to a stirrer, a thermometer, a cooler and a nitrogen inlet was installed so that monomers, emulsifiers and polymerization initiators were continuously added, and the reactor was filled with nitrogen, containing 30 wt% based on 100 parts by weight of A monomer mixture of acrylonitrile, 66wt% 1,3-butadiene and 4wt% methacrylic acid, adding 2 parts by weight of sodium alkylbenzene sulfonate, 0.5 parts by weight of tertiary dodecyl mercaptan, 2 parts by weight of Sodium methallyl sulfonate and 140 parts by weight of deionized water, and the temperature was raised to 40°C.

[0070] After heating, 0.3 parts by weight of a polymerization initiator potassium persulfate was added, and the polymerization reaction was terminated by adding 0.1 parts by weight of sodium dimethyldithiocarbamate when the conversion rate reached 95%. Unreacted monomers were removed through a deodorization step, an...

Embodiment 2

[0078] Except for using 5 parts by weight of sodium methallyl sulfonate instead of using 2 parts by weight of sodium methallyl sulfonate, a composition for dip molding and The physical properties of the glove-shaped dip-molded article are shown in Tables 1-3 below.

Embodiment 3

[0080] Except for using 10 parts by weight of sodium methallyl sulfonate instead of using 2 parts by weight of sodium methallyl sulfonate, a composition for dip molding and The physical properties of the glove-shaped dip-molded article are shown in Tables 1-3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com