Method for producing a plasma jet and plasma source

A plasma source and plasma technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of unsuitable size, high cost, and complex structure of plasma processing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

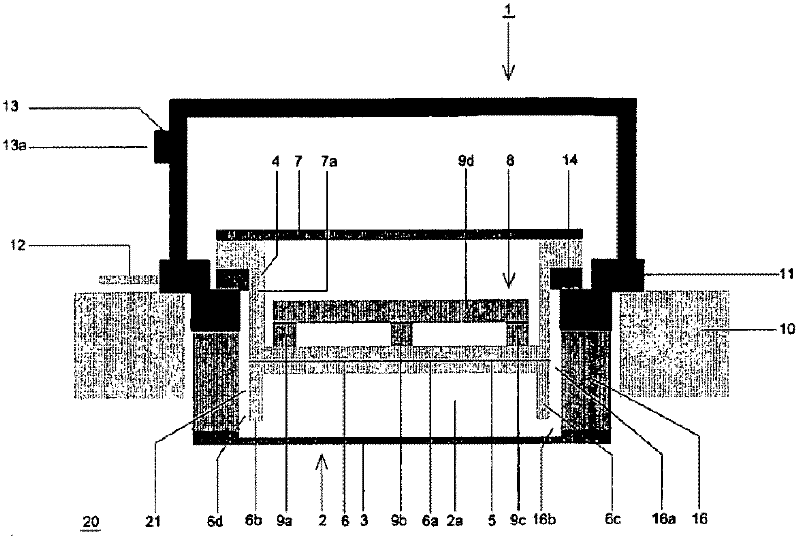

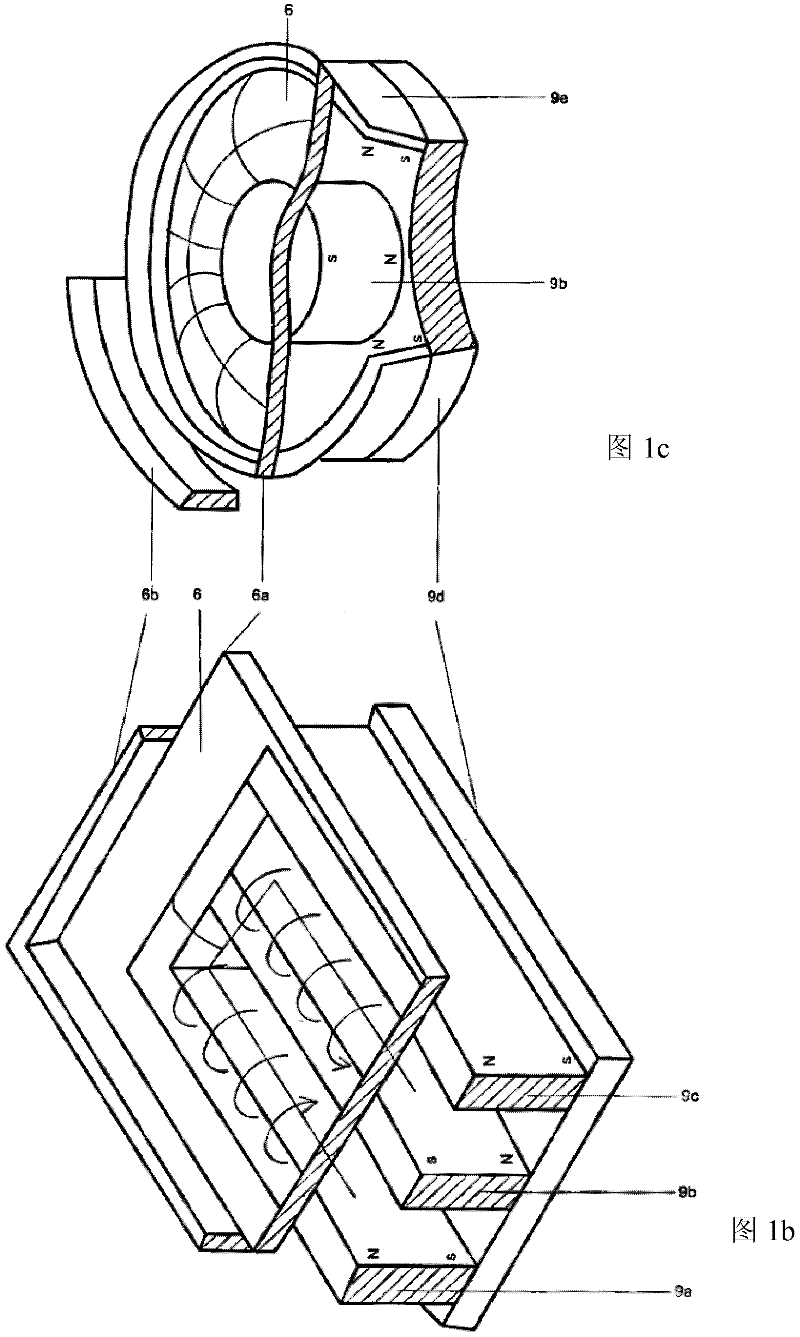

[0059] Figure 1a The schematic diagram shows a cross section of a high-frequency plasma source 1 installed in a vacuum chamber 10 according to the present invention. The high-frequency plasma source 1 has a plasma container 2, an extraction electrode 3 and a high-frequency electrode device 4. The process gas and reaction gas, such as argon and oxygen, can be introduced into the plasma container 2 through the gas input device 12.

[0060] The plasma container 2 has a front surface and a back surface, and the plasma chamber 2a is located between them. In addition, the plasma container 2 has side walls 16, which extend into the interior 20 of the vacuum chamber 10 and are provided with extraction electrodes 3 constituting the front surface of the plasma container 2 on their end surfaces. These electrodes are thus opposed to the interior of the vacuum chamber. 20 permeable defines the plasma chamber 2a. The lead electrode 2 can also be constructed in a curved manner.

[0061] The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com