High voltage iii-nitride semiconductor devices

A technology of nitride and nitride layer, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as current collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

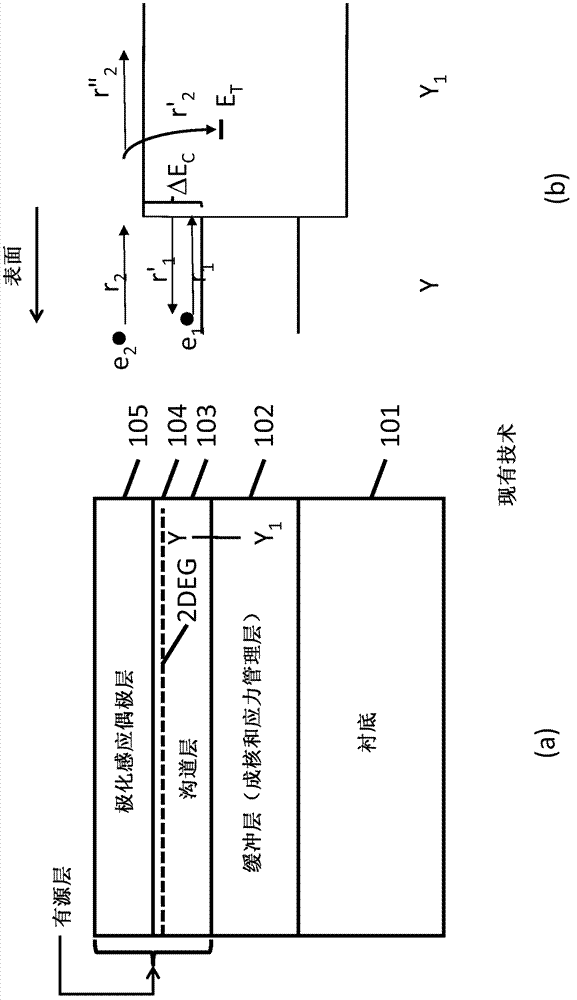

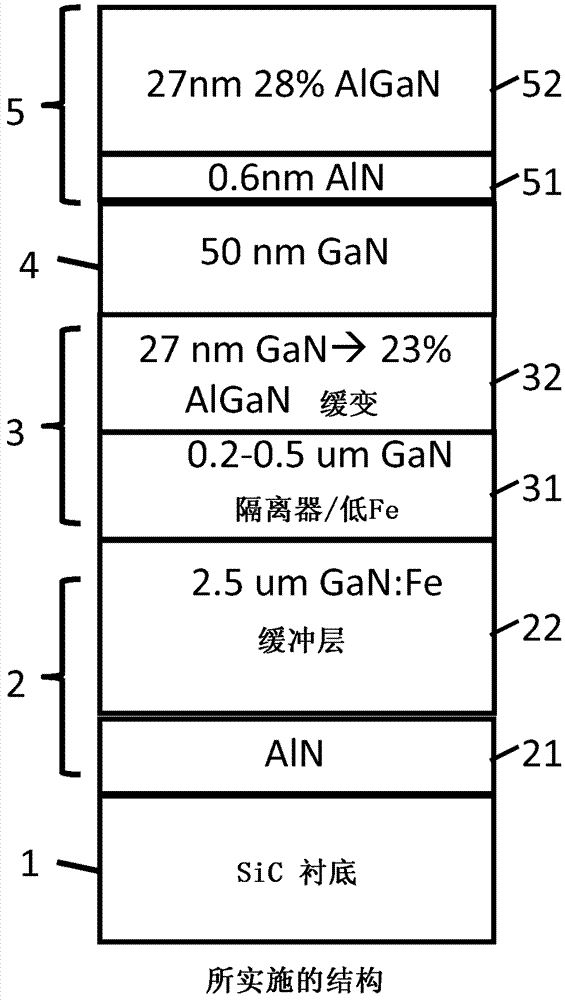

[0022] A device structure in which a dispersed barrier layer is included between the channel layer and the buffer layer of a III-N semiconductor device confines carriers to the channel layer such that dispersion or current collapse due to trapping in the buffer layer is minimized . The term dispersion barrier layer describes a layered structure in a III-N device that reduces electron trapping in the buffer layer and thus reduces drain current dispersion or drain current collapse and increases output. Here, the terms dispersion and current collapse are synonymous for the decrease in drain current due to electron trapping. Additionally, the buffer layer can be made sufficiently insulating, such as by intentional doping to prevent leakage of the buffer layer. To reduce trapping and current collapse, dispersed barrier layers can alleviate the need to grow thick channel or buffer layers. The barrier layer can further eliminate the need to optimize the trade-off between reducing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com