Resin composition and preparation method thereof

A resin composition and resin technology, applied in the field of polymer resin and its preparation, can solve the problems of lack of pigments, affecting the appearance of products, etc., and achieve the effects of reducing streamlines and high market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

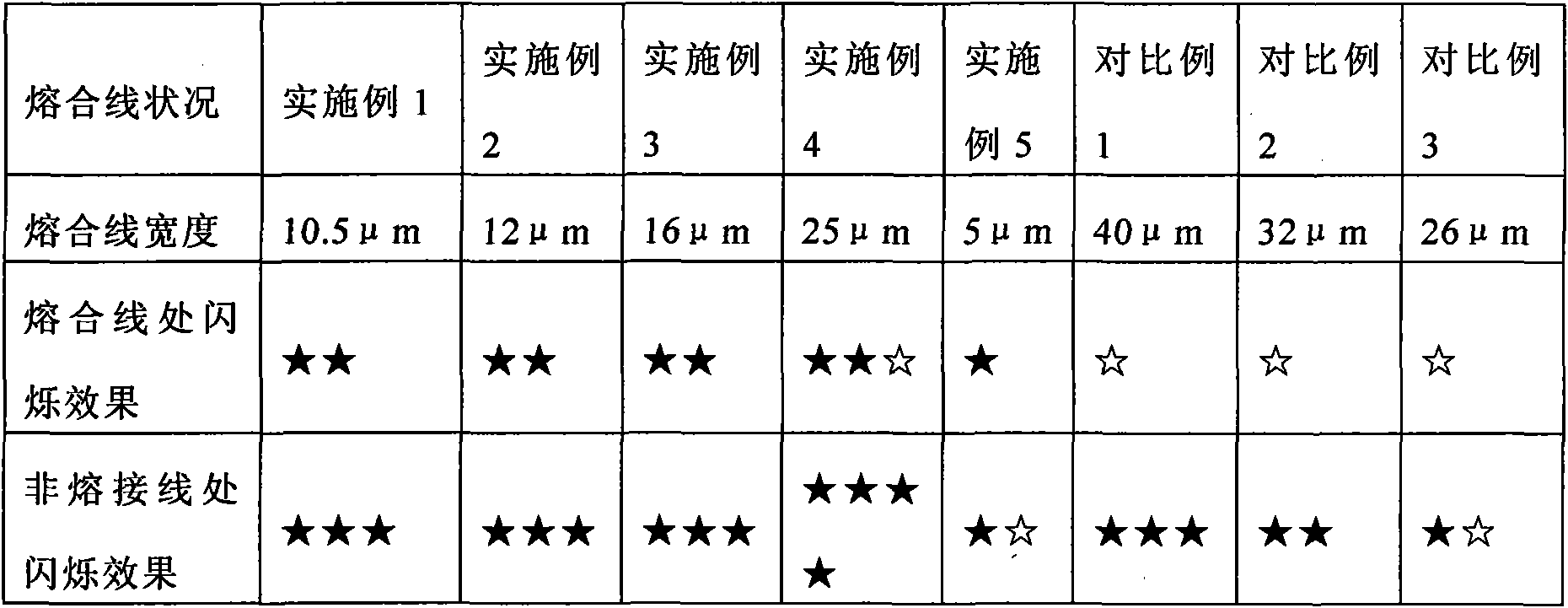

Examples

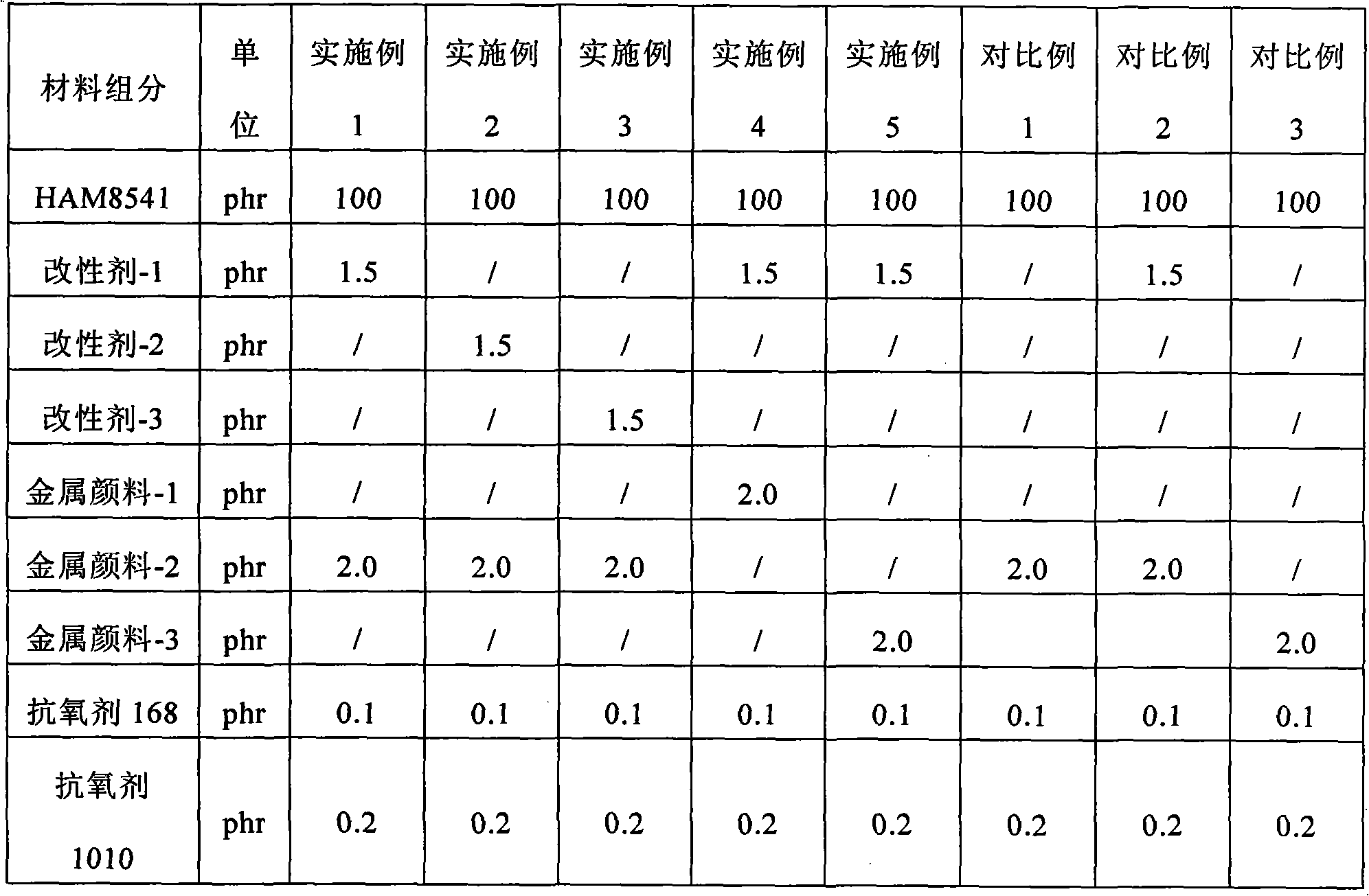

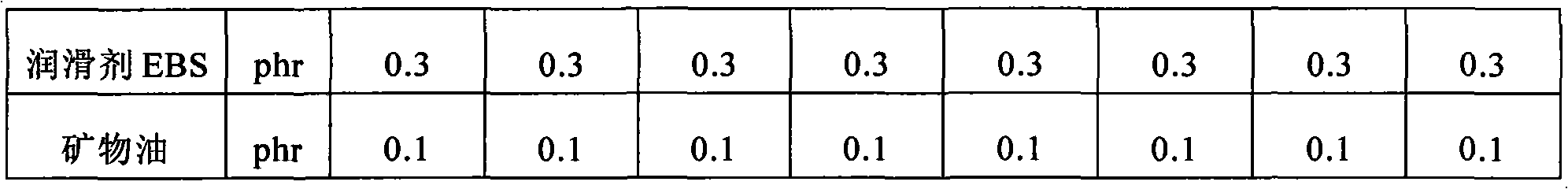

Embodiment 1~5

[0053] 1) Premix part of PMMA (80%) with other components except metallic pigments and mineral oil in a high-speed mixer in a certain proportion for 5-10 minutes;

[0054] 2) Pre-mix the remaining PMMA (20%) and mineral oil in a low-speed mixer for 3-5 minutes in a certain proportion, then add metal pigments and mix for 5 minutes, so that the metal pigments can be evenly distributed in the resin;

[0055] 3) Through a twin-screw extruder, 1) is added from the upstream feeding port, and 2) is added from the downstream feeding port to carry out the steps of melt extrusion, drawing, cooling, and pelletizing to obtain a resin composition with excellent appearance .

Embodiment 6

[0079] A preparation method of a resin composition, characterized in that the method comprises the following steps:

[0080] (1) Prepare materials according to the following components and parts by weight: 100kg of transparent resin, 0.2kg of modifier for bridging structure, 0.3kg of metallic pigment, 0.3kg of lubricant, 0.1kg of antioxidant, and 0.1kg of mineral oil; in addition, It can also include 0.3kg of antistatic agent, wherein the transparent resin is commercially available PMMA, the modifier of the bridge structure is a cross-linked methacrylic acid copolymer, the microscopic shape is spherical, the particle size is 2 μm, the transparent resin and The refractive index difference of the modifier with bridging structure is 0.04, the rheological viscosity of the modifier with bridging structure is much larger than that of the selected transparent resin and metal aluminum pigment, the aspect ratio is 1:1, and the lubricant is silicone oil , the antioxidant is Irganox 1010...

Embodiment 7

[0085] A preparation method of resin composition, the method comprises the following steps:

[0086] (1) Prepare materials according to the following components and parts by weight: 100kg of translucent resin, 3kg of modifier of bridge structure, 4kg of metallic pigment, 2kg of lubricant, 1kg of antioxidant, 0.3kg of mineral oil; in addition, can also include 0.1kg of the mixture of flame retardant and light stabilizer, wherein the translucent resin is a commercially available GPPS and PETG mixture, the modifier of the bridge structure is a cross-linked cross-linked styrene copolymer, and the microscopic shape is spherical, The particle size is 150μm, the refractive index difference between the transparent resin and the modifier with bridge structure is 0.1, and the rheological viscosity of the modifier with bridge structure is much larger than the selected translucent resin and metal titanium oxide pigment. The ratio is 15:1, the lubricant is silicone oil, and the antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com