Oil shale in-place destructive distillation mining method and simulated experiment system thereof

A mining method and simulation experiment technology, applied in the direction of production fluid, earthwork drilling, measurement, etc., can solve the problems of low shale oil recovery rate, low accelerated heat transfer rate, etc., to improve fracture development and permeability, improve The effect of recovery factor and heat transfer rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

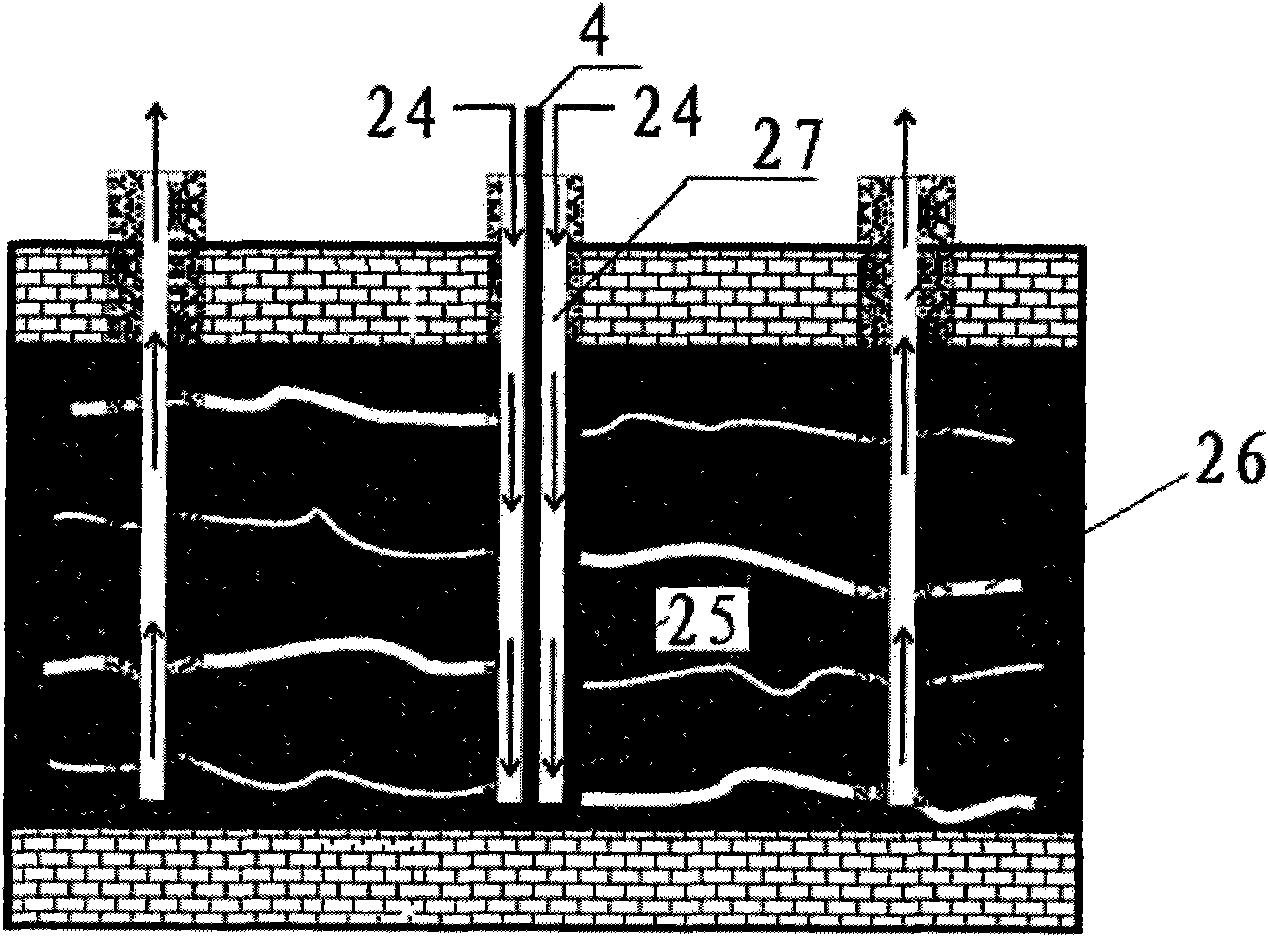

[0036] see figure 1 , the embodiment of the present invention provides an oil shale dry distillation mining method in situ, according to the following steps,

[0037] Step 1, creating fractures in the shale layer, specifically, the present invention uses the fracturing technology in crude oil exploitation to create rock formation cracks 26 in the shale layer, so as to improve the fracture development and permeability of the shale layer;

[0038] Step 2, performing direct conduction heating on the oil shale, and simultaneously injecting gas into the direct conduction heating area.

[0039] Specifically, in this example, the electric heating rod 4 is used to conduct direct conduction heating to the oil shale, and at the same time, carbon dioxide 24 is passed into the vicinity of the heating well 27 to assist in convective heating, and the heat near the heating pipe is carried to the Far and deep oil shale layer 25, thereby improving the efficiency of heat conduction of oil shal...

Embodiment 2

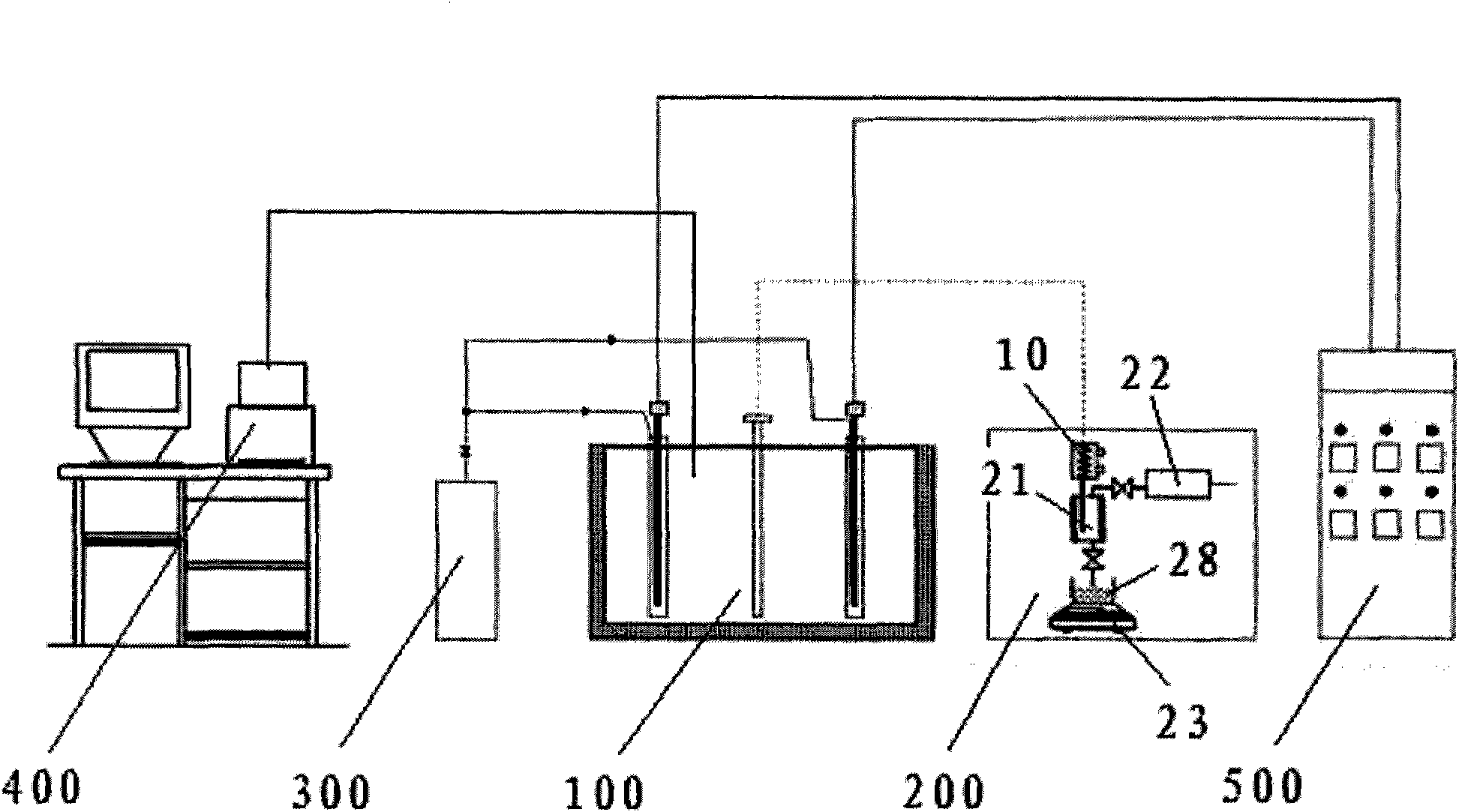

[0041] Such as figure 2 As shown, the embodiment of the present invention also provides a simulation experiment system applied to the mining method, the system includes a heating device 100 and a measuring device 200 connected to the heating device 100, a gas injection device 300, a computer 400 and the control device 500. Wherein, the heating device 100 is used for heating the oil shale and deriving the pyrolysis product of the oil shale, and the measuring device 200 is used for condensation, collection and measurement of the pyrolysis product of the oil shale, so The gas injection device 300 is used to provide gas, the computer 400 is used to analyze data, and the control device 500 is used to control the heating temperature of the heating device 100 .

[0042] Specifically, the computer 400 includes computer data processing software and data input and output devices (such as a keyboard).

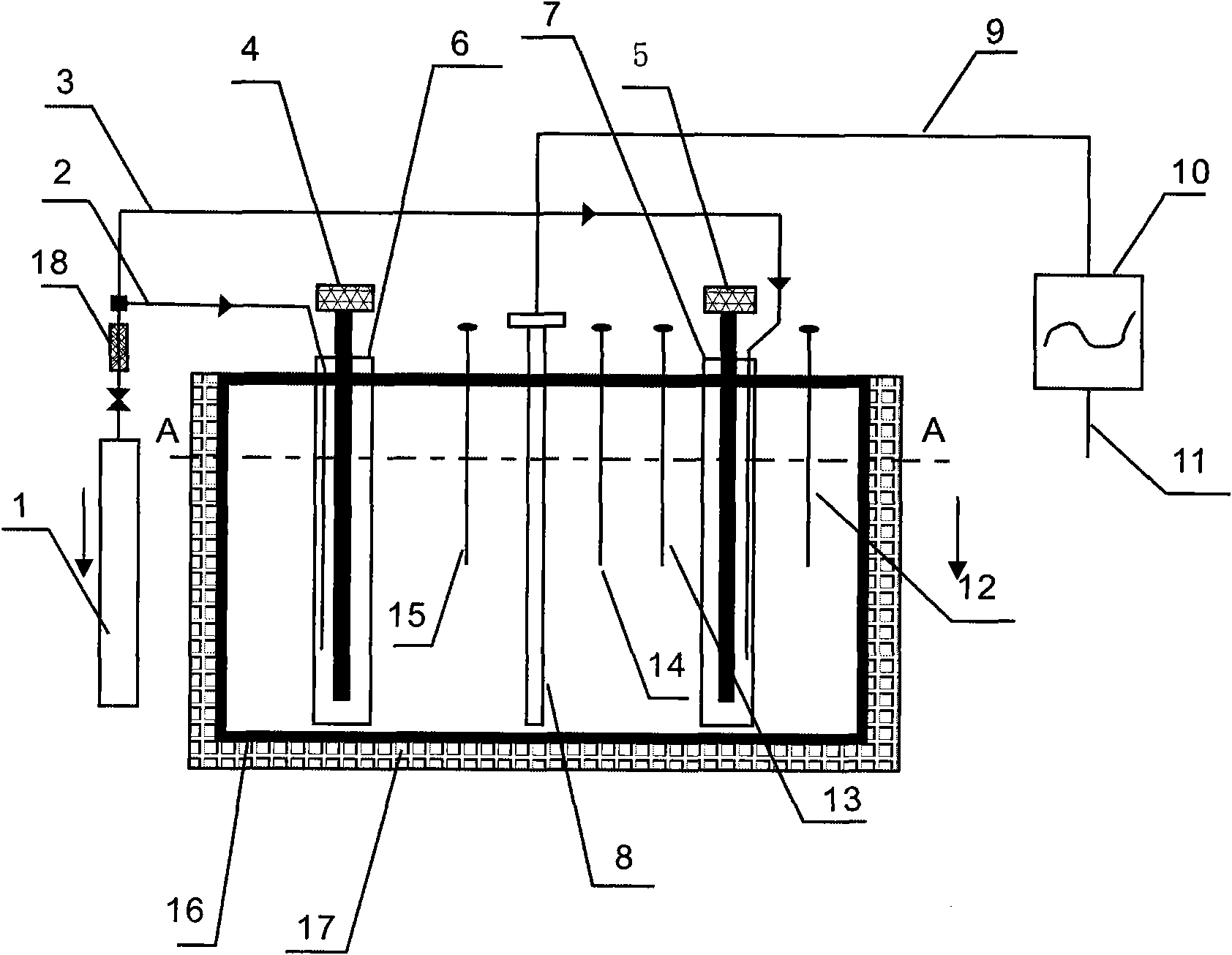

[0043] Specifically, such as image 3 As shown, the heating device includes a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com