Fatigue loading device for reinforced concrete duration test

A durability test and fatigue loading technology, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure test material strength, etc., can solve the problems of negligible non-durable load, difficulty in ensuring accuracy, and large labor load. , to achieve the effect of true and reliable test parameters, convenient operation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

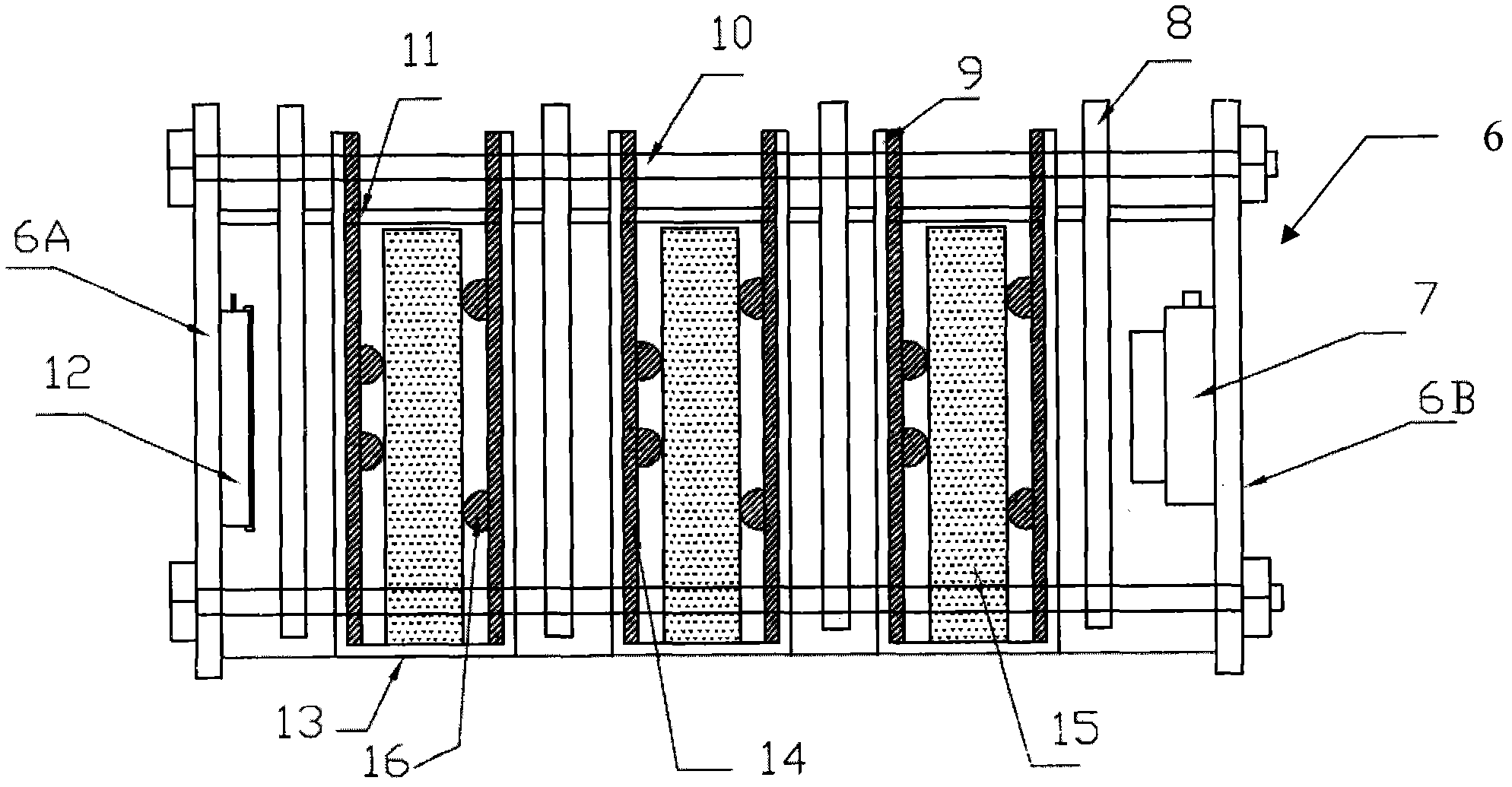

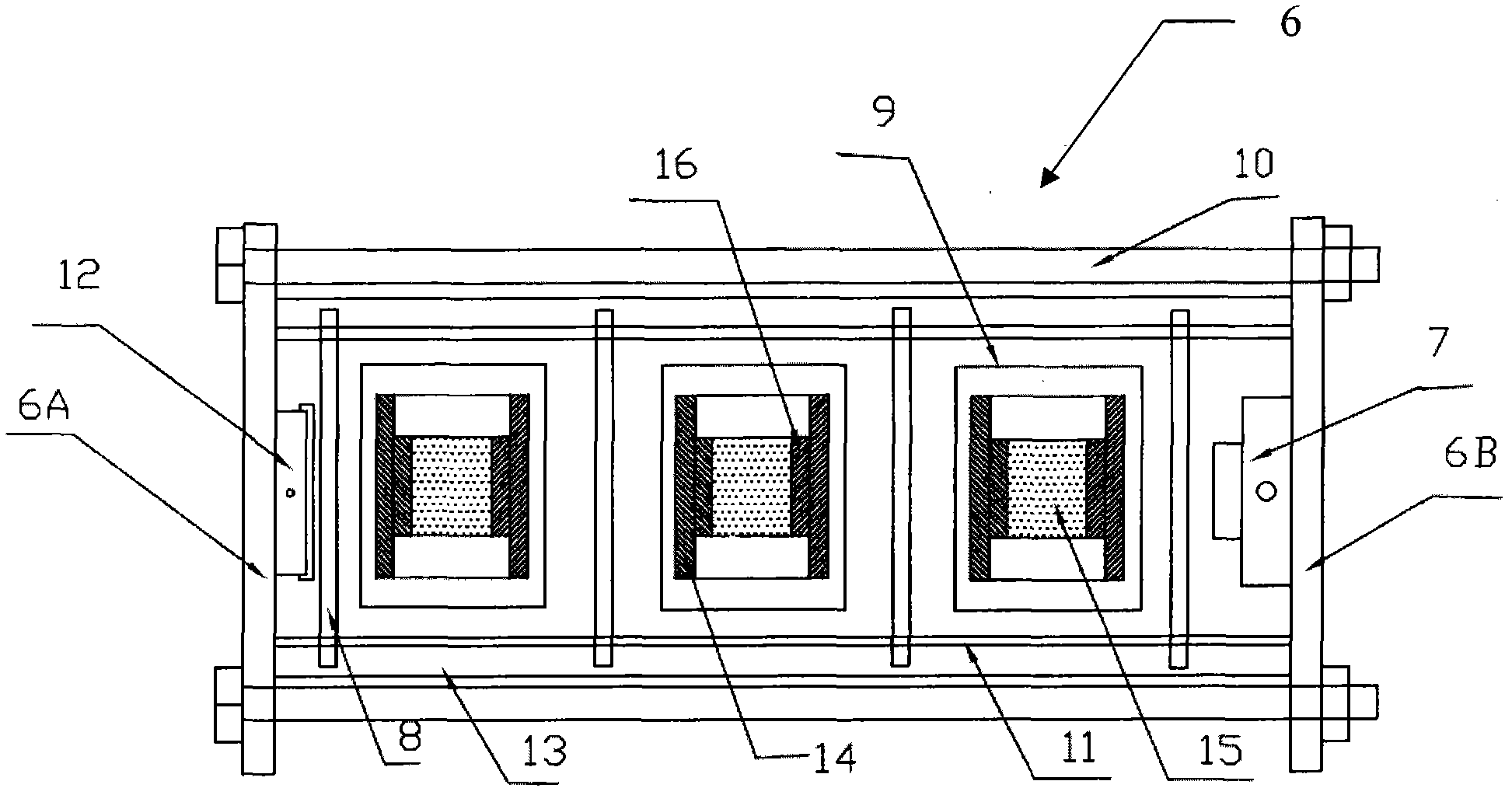

[0035] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

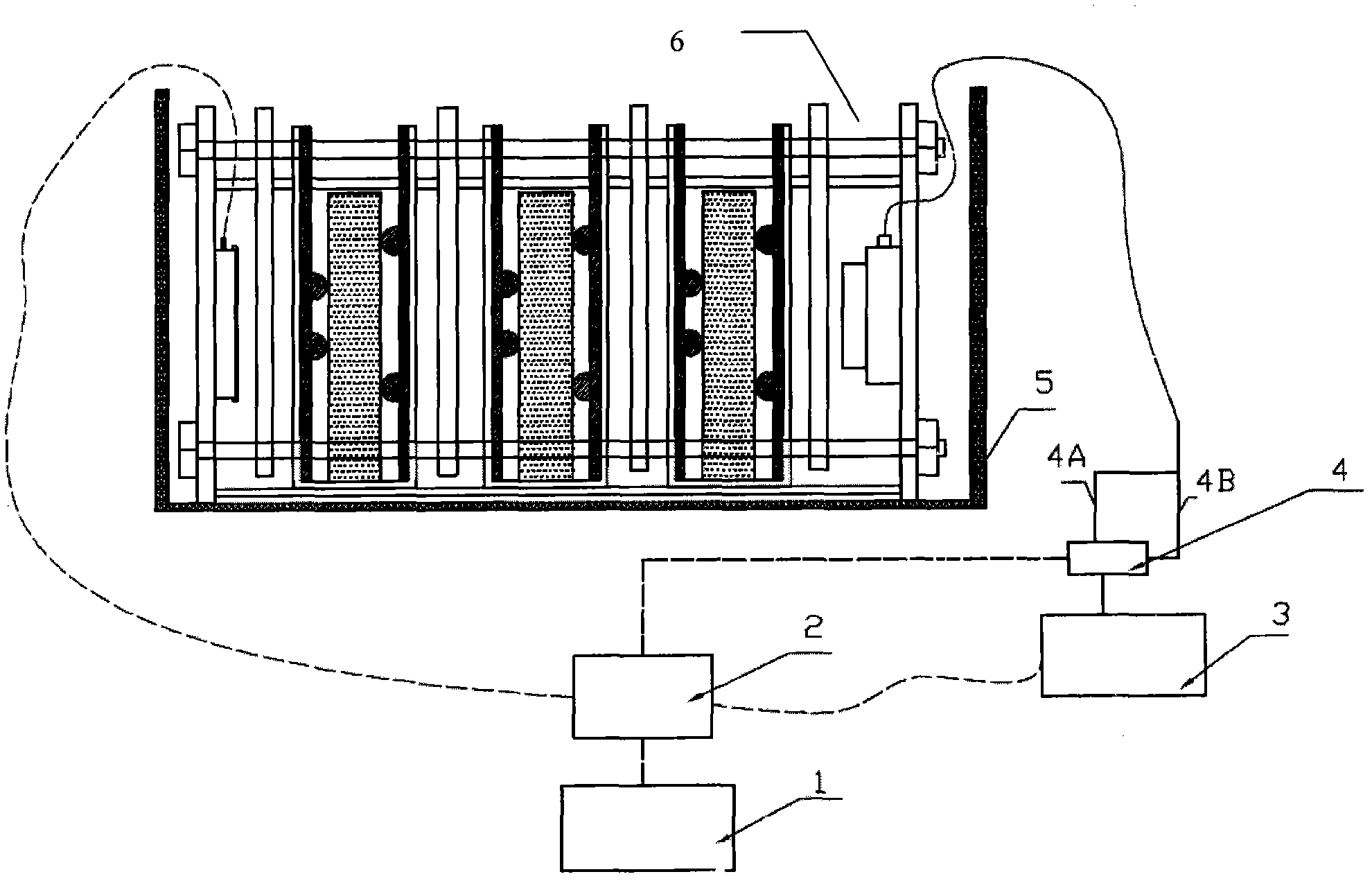

[0036] see figure 1 As shown, the fatigue loading device for reinforced concrete under the conditions of freeze-thaw cycle and saline solution erosiveness of the present invention includes a touch screen 1, a controller 2, an electric hydraulic pump 3, a three-way electromagnetic reversing valve 4, a fast freeze-thaw cycler box 5 and Load component6. in:

[0037] The touch screen 1 is a man-machine dialogue interface, which is connected with the controller 2 through a data line, through which the requirements of the fatigue loading process can be input into the controller 2, and the change of the fatigue load can be observed in real time during the test;

[0038] The controller 2 is a programmable logic controller PLC, which is the computing center of the whole device, and is responsible for collecting pressure sensors 12 from the loading asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com