Manufacture method of diffractive optical element with large aspect ratio

The technology of a diffractive optical element and a manufacturing method, which is applied in the field of semiconductor microfabrication, can solve the problems of easy collapse of photoresist, and achieve the effect of easy batch preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

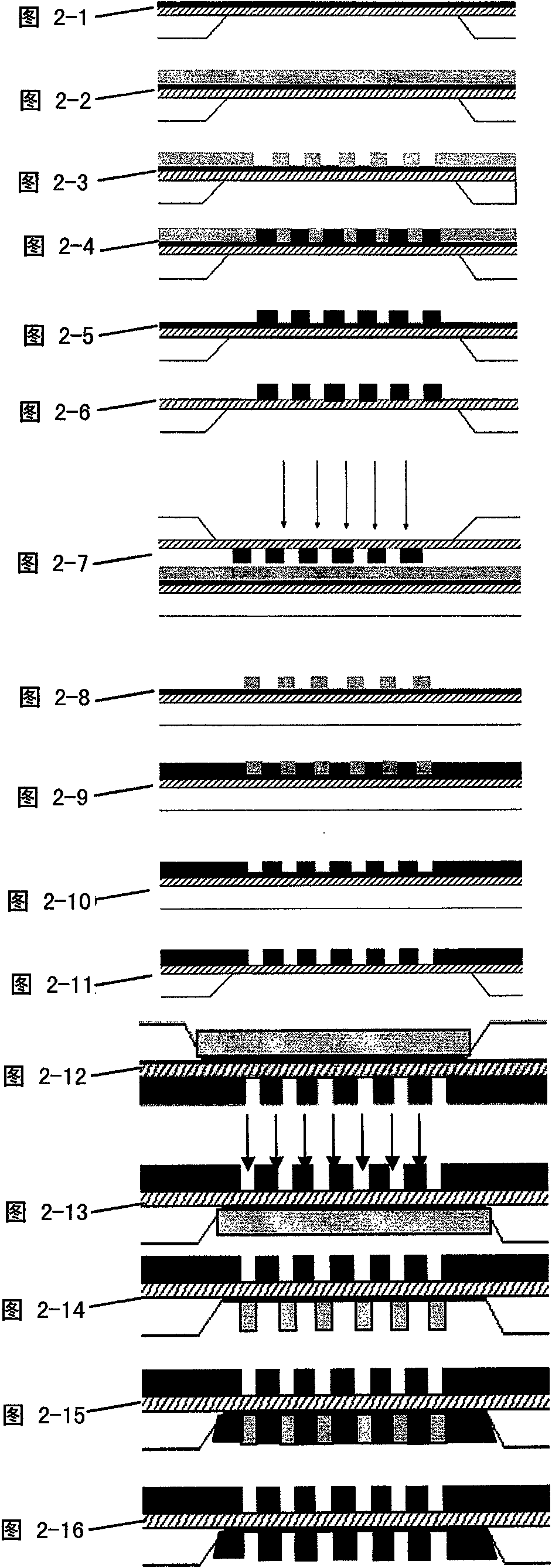

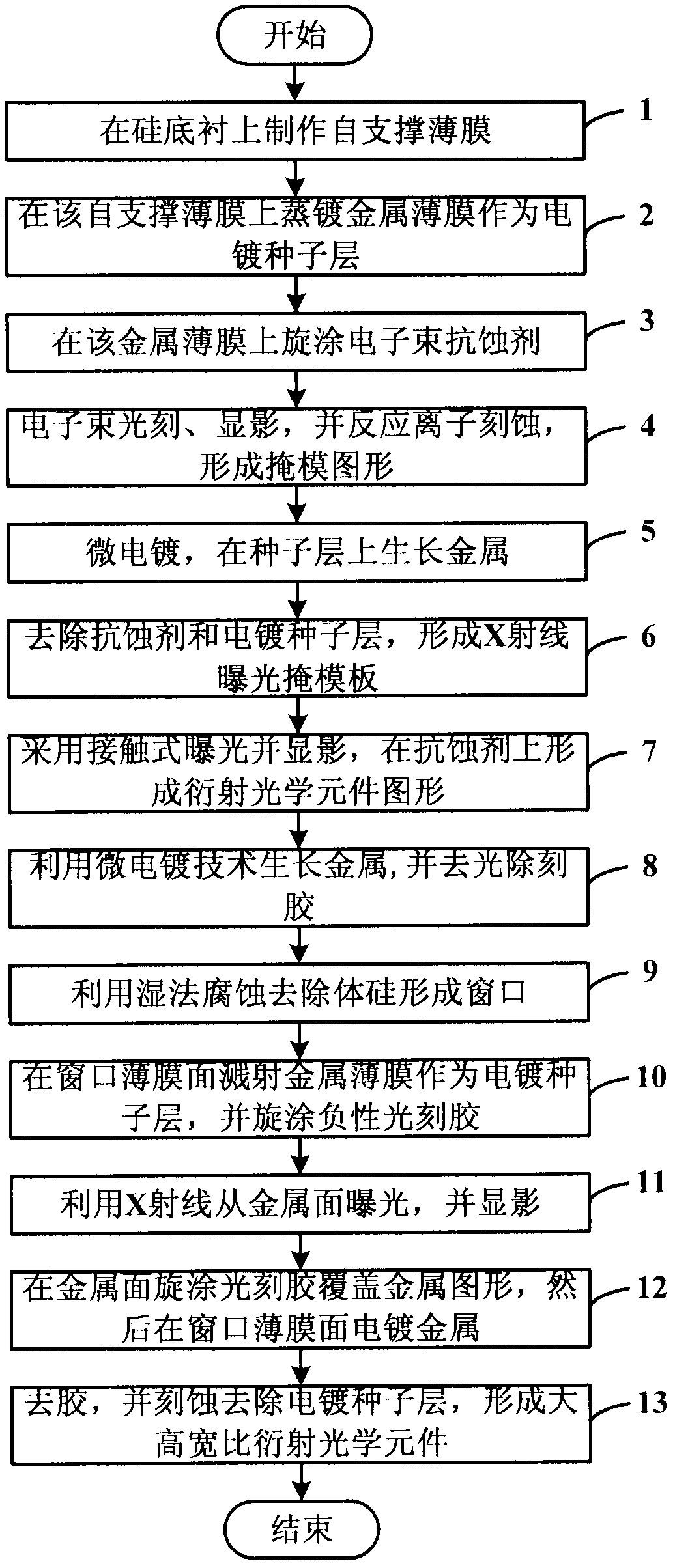

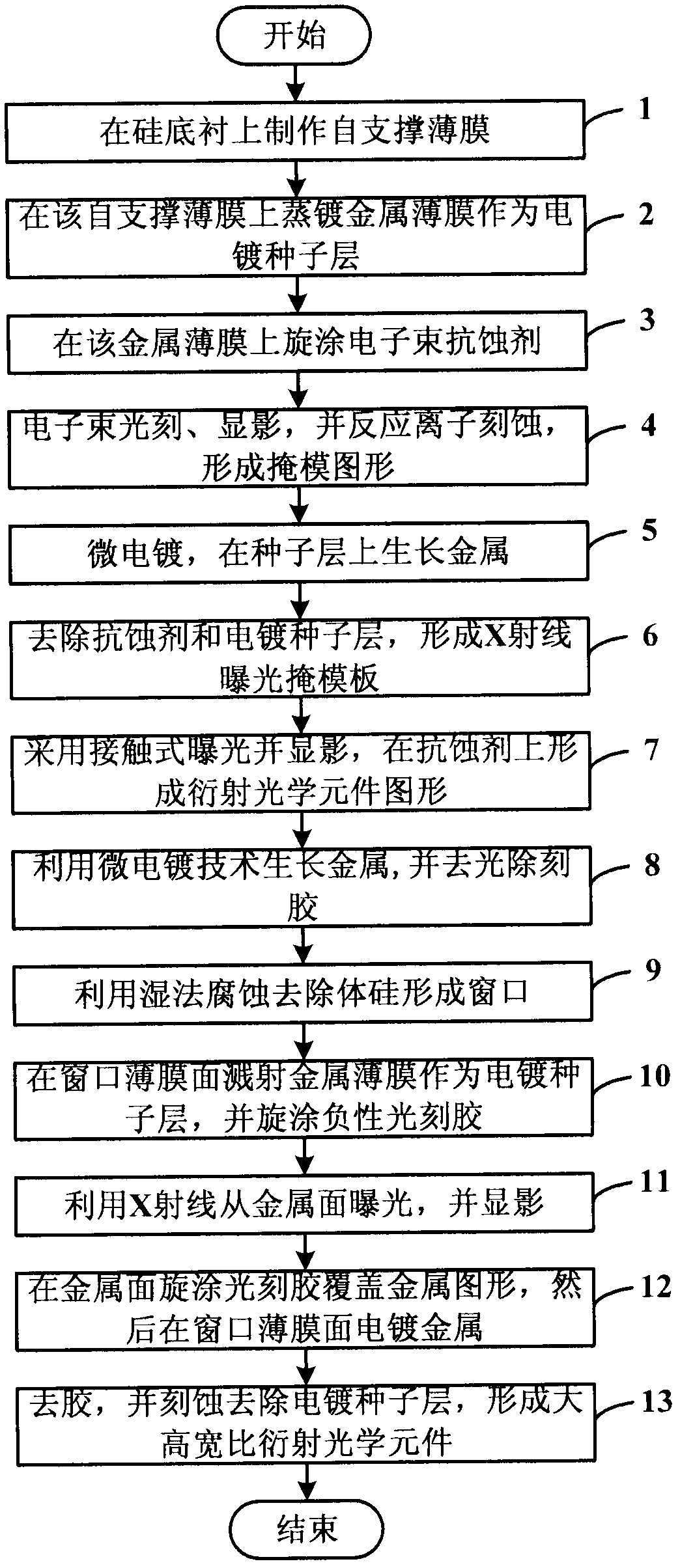

[0040] The method for producing diffractive optical elements with large aspect ratio based on the combination of electron beam lithography and X-ray exposure provided by the present invention uses electron beam direct writing to produce X-ray exposure mask, and uses contact exposure to realize transmission diffractive optics The production of the element involves sputtering and electroplating a seed layer on the surface of the transmissive film substrate, then spin-coating a negative photoresist, exposing it again with X-rays, developing, electroplating, and etching the electroplating seed layer, and then forming a large aspect ratio diffractive optical element.

[0041] Such as figure 1 as shown, figure 1 It is a flow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com