Series-excitation AC (Alternating Current) motor brush for soybean milk maker/juice extractor

A technology for AC motors and juice extractors, applied in the field of series-excited AC motor brushes, which can solve the problems of brush wear, wear resistance, dust wear, and deterioration of brush performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

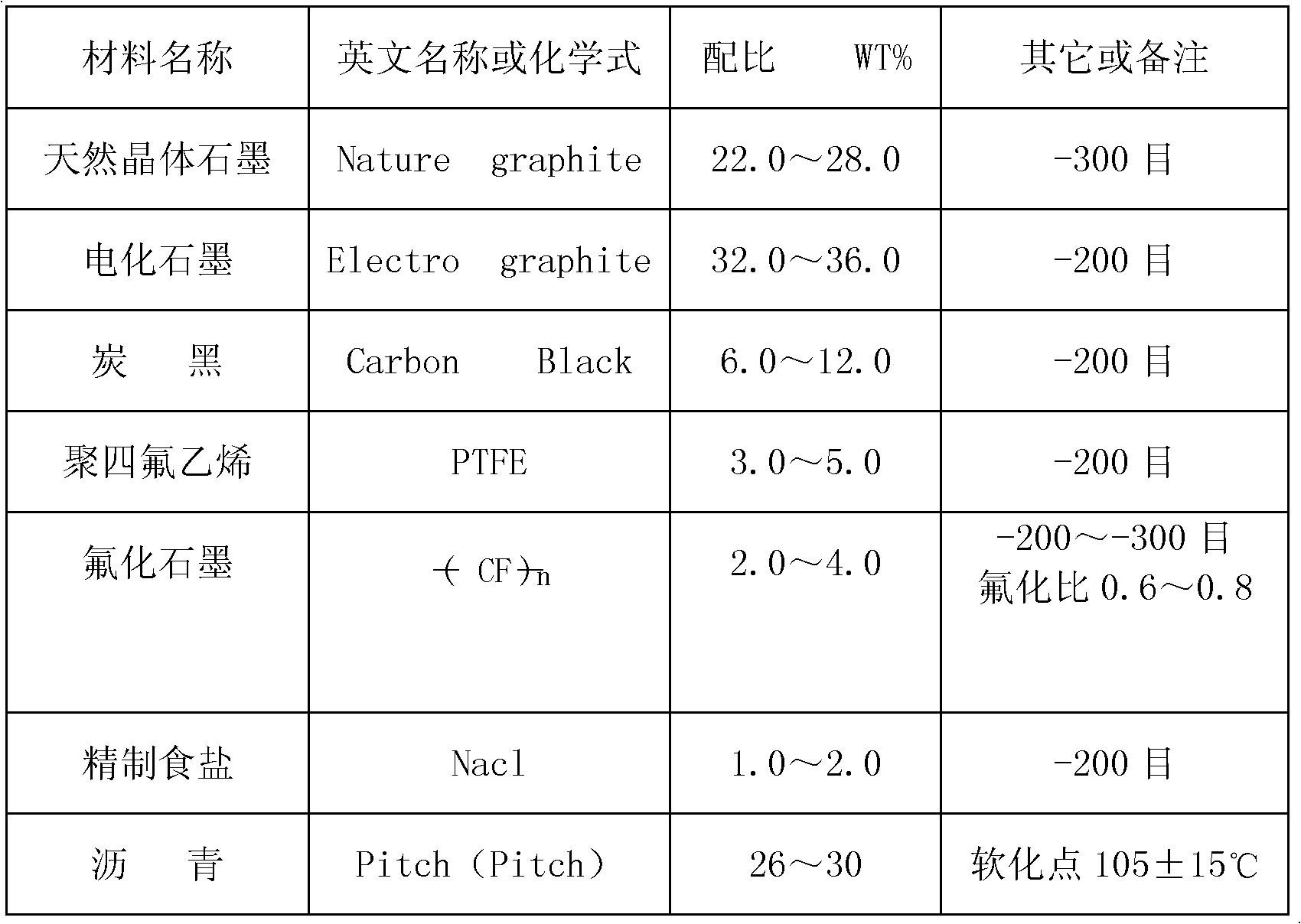

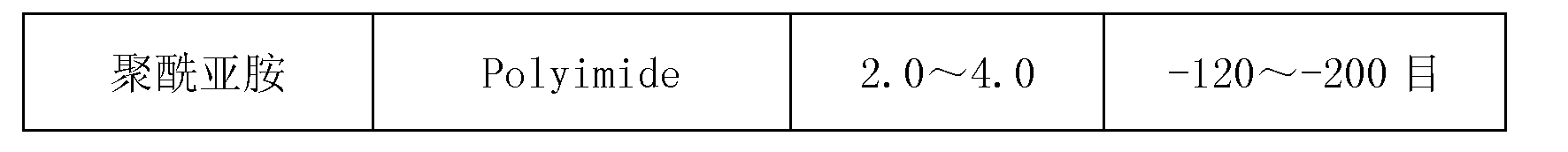

Embodiment 1

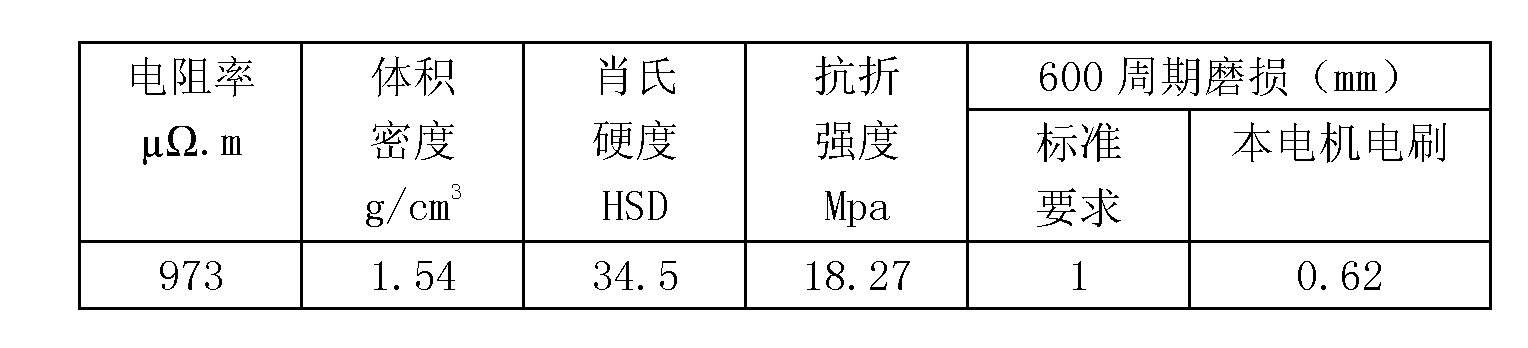

[0031] Take 22 kilograms of natural crystal graphite, 35 kilograms of electrochemical graphite, 6 kilograms of carbon black, 4 kilograms of polytetrafluoroethylene, 3 kilograms of fluorinated graphite, and 1 kilogram of refined salt powder and put them into a mixing container, and heat and dry mix for 60 minutes. When the temperature reaches 120°C, add 26 kg of asphalt and 3 kg of polyimide, and continue heating and kneading for 210 minutes to make each group fully kneaded evenly, then turn off the heating power, and let the kneaded paste material be free Cooling and granulation, when the temperature of the material is 70°C, discharge the material from the mixing container, and freely cool to room temperature; then grind the mixture granules, pass through a 160-mesh sieve, and mold them under a pressure of 16Mpa, and then put them in a protective The finished product can be obtained by roasting at a temperature of 600°C in an atmospheric environment.

[0032] Product of the pr...

Embodiment 2

[0035] Take 25 kilograms of natural crystal graphite, 33 kilograms of electrochemical graphite, 7 kilograms of carbon black, 3 kilograms of polytetrafluoroethylene, 2 kilograms of fluorinated graphite, and 1 kilogram of refined salt powder and put them into a mixing container, and heat and dry mix for 75 minutes, and wait for the material When the temperature reaches 130°C, add 27 kg of asphalt and 2 kg of polyimide, and continue heating and kneading for 180 minutes to make each group fully kneaded evenly, then turn off the heating power, and let the kneaded paste material be free in the kneaded state. Cooling and granulation, when the temperature of the material is 80°C, discharge the material from the mixing container, and freely cool to room temperature; then grind the mixture granules, pass through a 160 mesh sieve, and mold them under a pressure of 18Mpa, and then put them in a protective The finished product can be obtained by roasting at a temperature of 700°C under an a...

Embodiment 3

[0039] Take 28 kilograms of natural crystal graphite, 32 kilograms of electrochemical graphite, 6 kilograms of carbon black, 3 kilograms of polytetrafluoroethylene, 2 kilograms of fluorinated graphite, and 1 kilogram of refined salt powder and put them into a mixing container, and heat and dry mix for 90 minutes. When the temperature reaches 140°C, add 26 kg of asphalt and 2 kg of polyimide, and continue heating and kneading for 200 minutes to make each group fully kneaded evenly, then turn off the heating power, and let the kneaded paste material be free Cooling and granulation, when the temperature of the material is 75°C, discharge the material from the mixing container, and freely cool to room temperature; then grind the mixture granules, pass through a 160-mesh sieve, and mold them under a pressure of 17Mpa. The finished product can be obtained by roasting at a temperature of 650°C under an atmospheric environment.

[0040] Product of the present invention reaches technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com