Filter membrane module cleaning method and cleaning apparatus

A technology for cleaning equipment and filtration membranes, applied in chemical instruments and methods, membranes, ultrafiltration, etc., can solve problems such as uneven cleaning, and achieve the effect of reducing costs and inhibiting the decline of cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

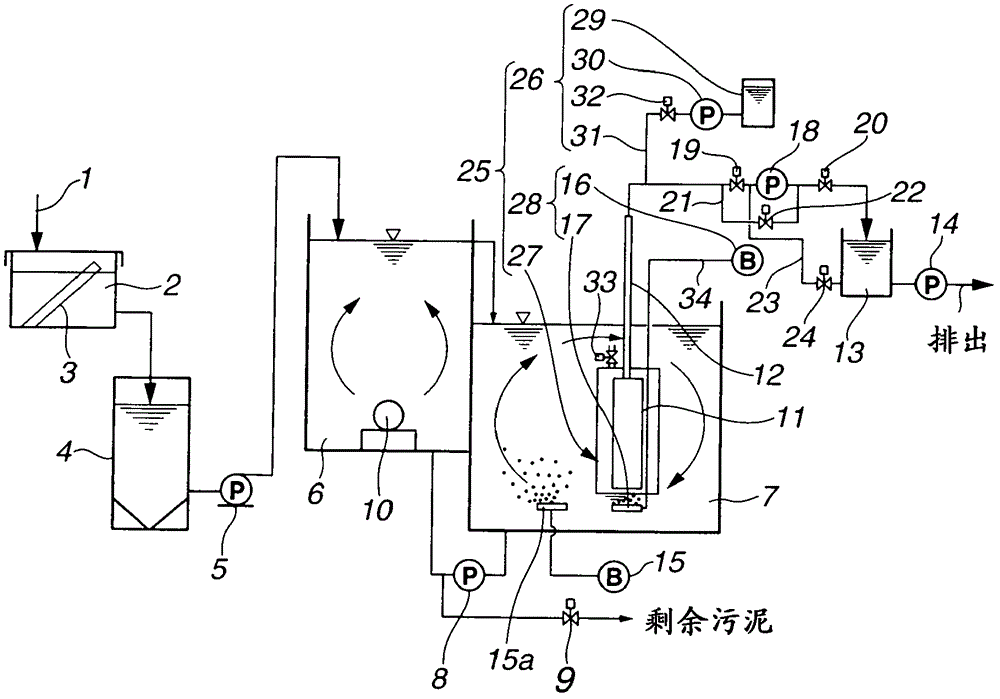

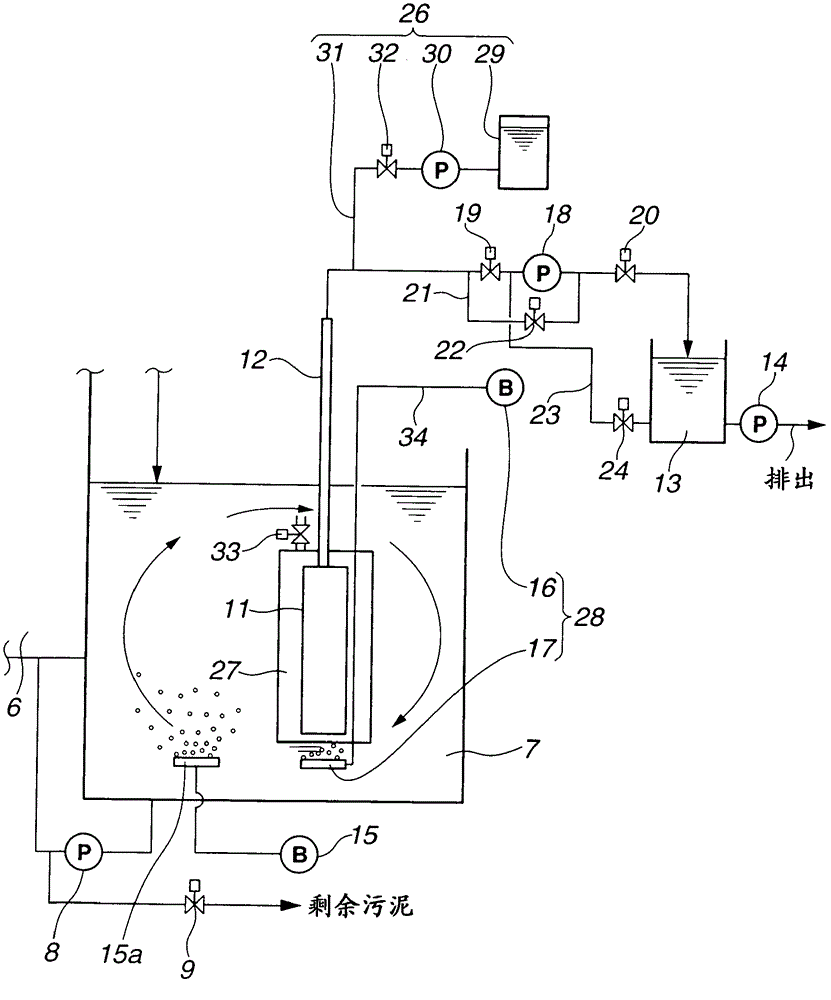

[0032] figure 1 is a schematic diagram of a sewage treatment system equipped with the filter membrane module cleaning apparatus of the present invention, which system operates by implementing the membrane bioreactor method (MBR). In the shown sewage treatment system, raw water 1 such as domestic sewage, industrial wastewater, etc. is introduced into a screen tank 2 and filtered by a fine mesh 3 to thereby remove solid waste, and guided to a flow regulating tank 4 . Then, with the help of the pump 5 regulating the flow, the raw water from which the solid waste has been removed is guided from the flow regulating tank 4 to the denitration tank 6 and then to the reaction tank 7 with the gravity flow caused by the water level difference. Due to the operation of the return pump 8, water returns from the reaction tank 7 to the denitration tank 6, thereby forcing the activated sludge to circulate between and around the denitration tank 6 and the reaction tank 7, and a part of the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com