Method for producing a coated item by means of texture etching

An etching and coating technology, applied in the direction of equipment, cable/conductor manufacturing, conductors, etc. for the manufacture of conductive/semiconductor layers, to achieve the effect of improving conductivity and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

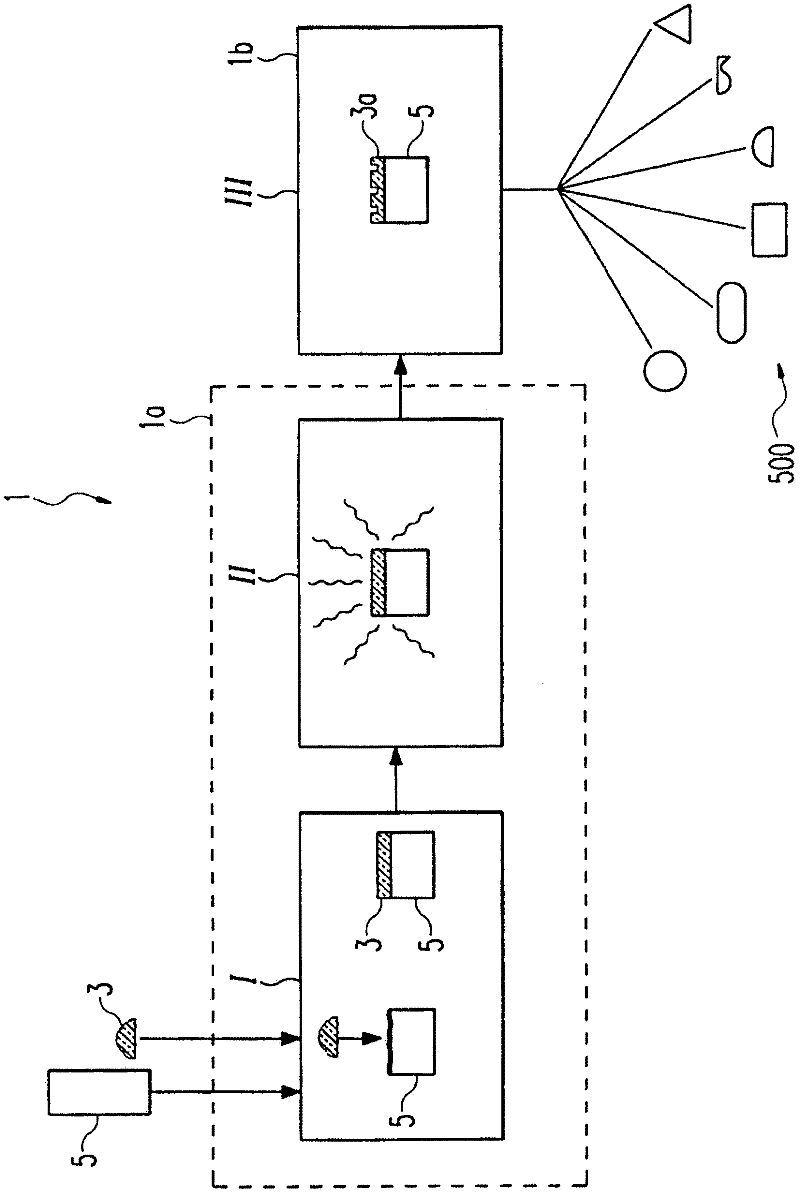

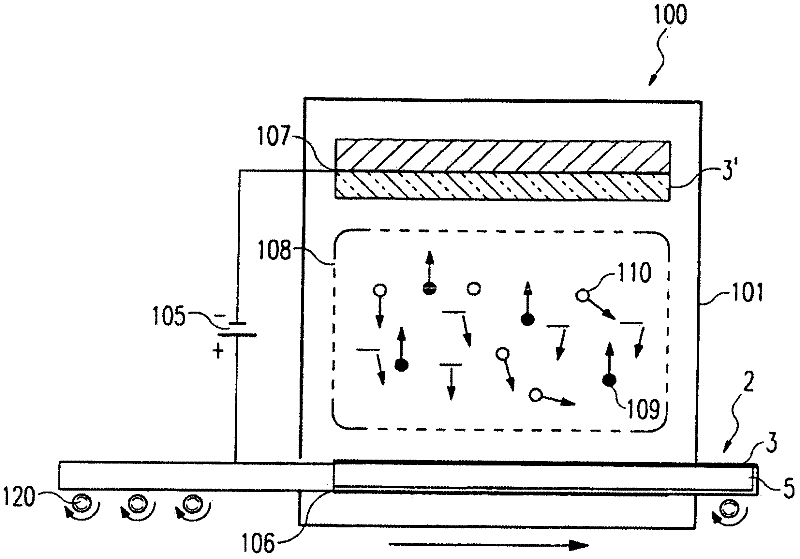

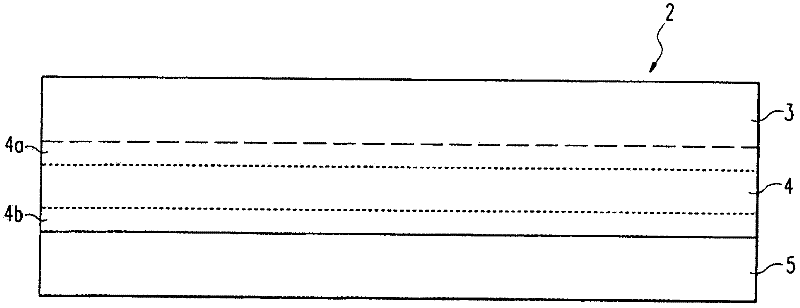

[0052] The reference numerals are consistent across all figures such that each component has the same reference numeral throughout the figures. First, the drawings will be described in detail. Two exemplary embodiments according to the present invention are described next.

[0053] figure 1 The method according to the invention is shown, with which the coated object 2 is produced in two or three method steps: I coating, II heating and III etching. The two method steps I and III form the solution according to the invention, whereas method step II, ie etching, can optionally be inserted between the two method steps I and III. The upper left corner shows the raw material, which is the coating material 3 and its carrier, the so-called substrate 5 , preferably consisting of glass.

[0054] The coating material is one or more metal oxides, which are called TCOs (transparent, conductive oxides). In method step I, the substrate 5 is coated with one or more metal oxides. In method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com