Motor driving device

A driving device and motor technology, which is applied in the direction of controlling electromechanical transmission device, suppressing motor vibration control, motor generator control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, use Figure 8 , 9 , 10 to illustrate the existing motor drive.

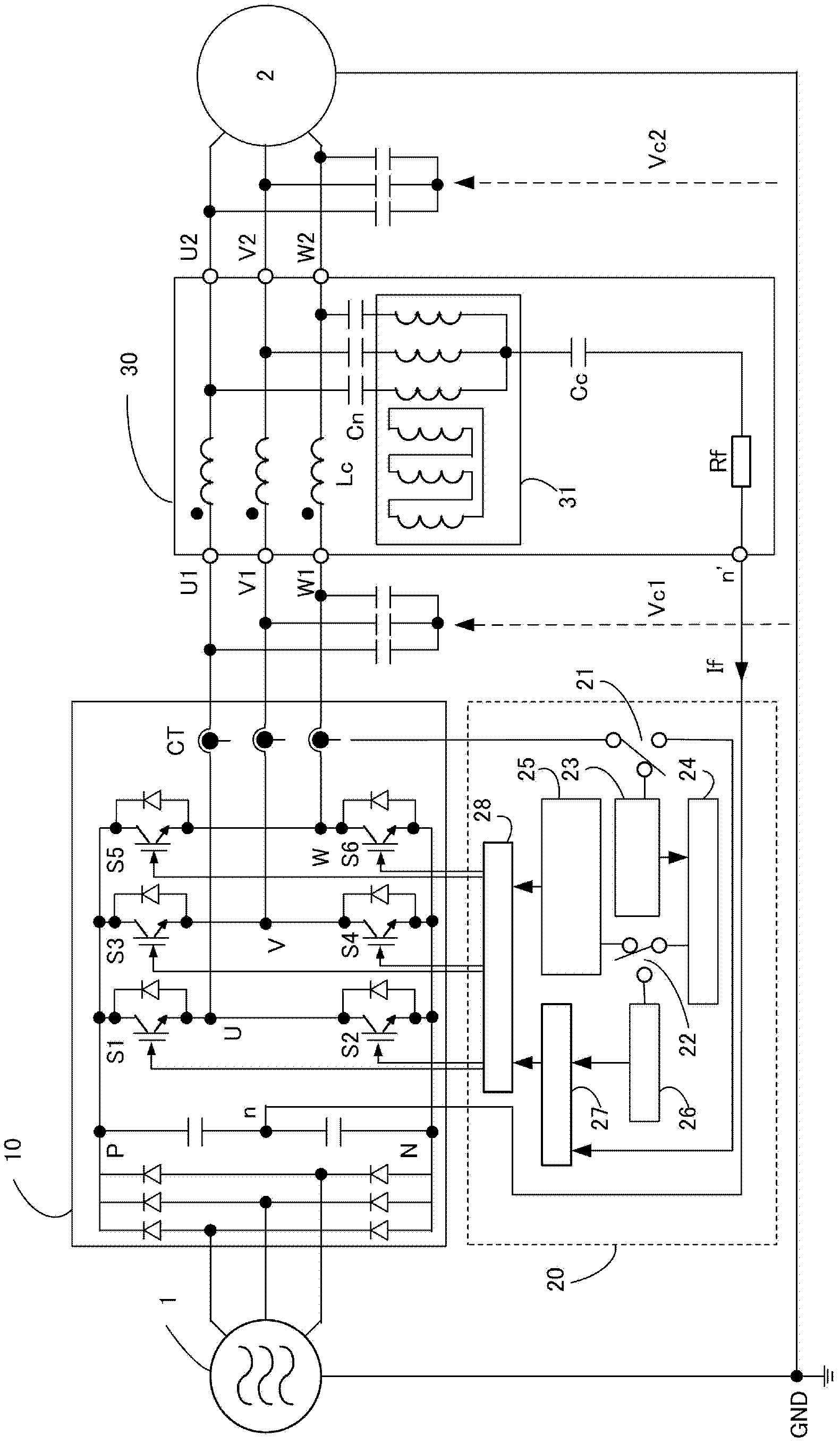

[0034] Figure 8 A schematic configuration diagram of a motor drive device including a common mode filter and a power conversion device is shown.

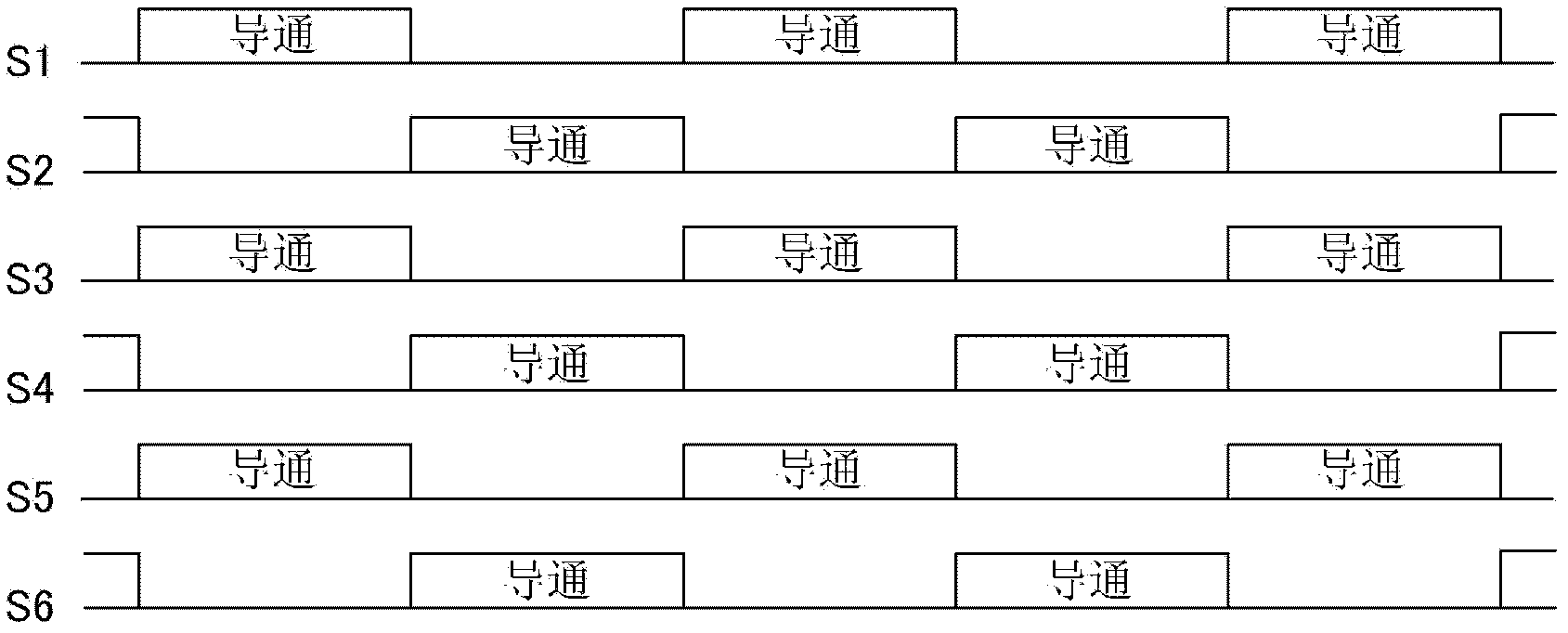

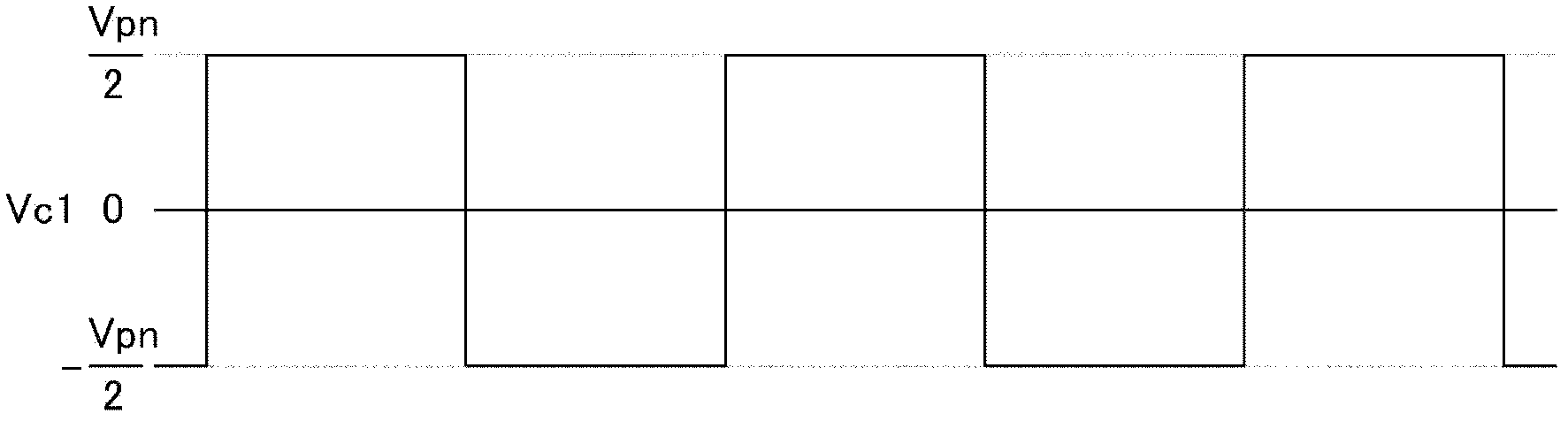

[0035] This motor drive device is constituted by a power conversion device (main circuit unit 10 , drive control unit 40 ) and a common mode filter 30 provided on the output side thereof. The AC power supply 1 is input to the main circuit part 10, and the switching elements S1-S6 in the main circuit part 10 are turned on and off according to the PWM driving signal from the drive control part 40, and the AC-DC conversion is performed, and then through the common The modulo filter 30 supplies power to the motor 2 .

[0036] In addition, in the drive control unit 40, the controller 47 is based on the output current detection signal from the current detector CT included in the main circuit unit 10, a command signal from a higher level (not shown), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com