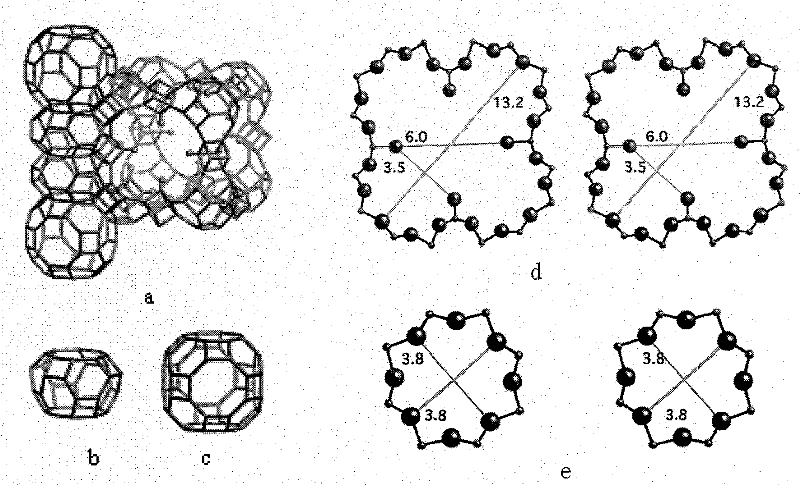

Method of synthesizing super large micropore aluminium phosphate molecular sieve in eutectic mixture

A technology of eutectic mixture and aluminum phosphate molecular sieve, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problem of long crystallization time of molecular sieve, and achieve low synthesis cost, environmental friendliness, low The effect of skeleton density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

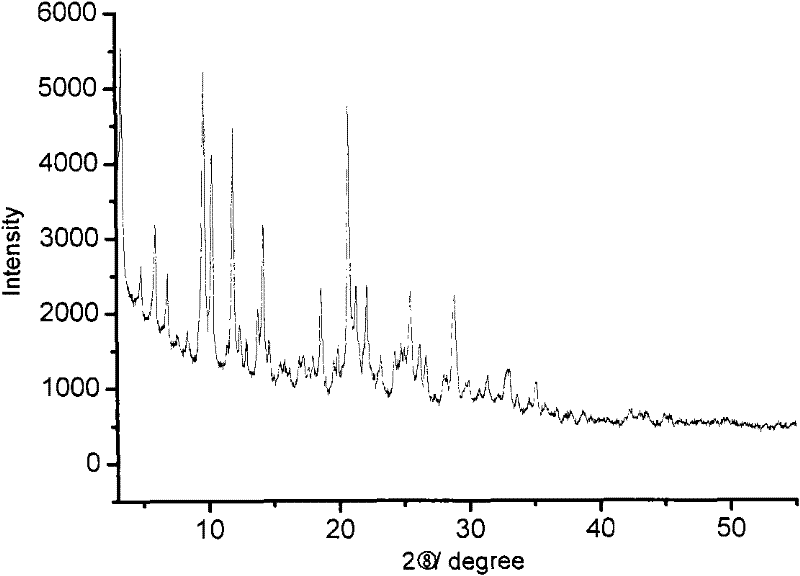

Embodiment 1

[0038] Add 60.0g of tetraethylammonium chloride-pentaerythritol eutectic mixture (TEAC-Pent, TEAC to Pent molar ratio is 0.82:1) into a 100ml beaker, heat up to 100°C, add 6.19g of 85wt% by magnetic stirring Phosphoric acid, 7.6g aluminum isopropoxide, evenly added dropwise 0.96g concentration of 40% hydrofluoric acid, stirred until uniform, then added 1.53g 2-methylimidazole (2-MIm), continued to stir until uniform to obtain the reaction precursor Reactants, where Al 2 o 3 :P 2 o 5 :F - The ratio of :TEAC:2-MIm is 1:1.42:0.53:4.88:0.50 (molar ratio). The above mixture was transferred to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene lining, placed in an oven at 180°C, and kept for 4 hours, then the reaction mixture was cooled to room temperature, 150ml of deionized water was added, stirred, and ultrasonically washed. The reactant was filtered to obtain a white solid powder, which was washed three times repeatedly, and the white powder was washed w...

Embodiment 2

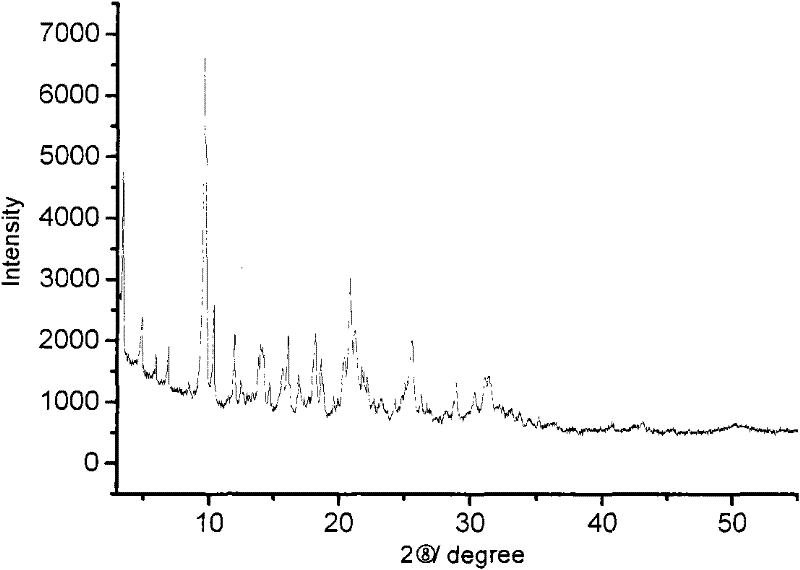

[0042] Add 60.0g of tetraethylammonium chloride-pentaerythritol eutectic mixture (TEAC-Pent, TEAC to Pent molar ratio is 0.41:1) into a 100ml beaker, heat up to 100°C, add 5.23g of 85wt% by magnetic stirring Phosphoric acid, 7.6g aluminum isopropoxide, evenly added dropwise 0.96g concentration of 40% hydrofluoric acid, stirred until uniform, then added 1.53g 2-methylimidazole (2-MIm), continued to stir until uniform to obtain the reaction precursor Reactants, where Al 2 o 3 :P 2 o 5 :F - The ratio of :TEAC:2-MIm is 1:1.20:0.53:2.66:0.50 (molar ratio). The above mixture was transferred to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene lining, placed in an oven at 180°C, and kept for 4 hours, then the reaction mixture was cooled to room temperature, 150ml of deionized water was added, stirred, and ultrasonically washed. The reactant was filtered to obtain a white solid powder, which was washed three times repeatedly, and the white powder was washed w...

Embodiment 3

[0044] 60.0g tetraethylammonium chloride-pentaerythritol eutectic mixture (TEAC-Pent) is added in the 100ml beaker, is warming up to 100 ℃, magnetic stirring adds 7.23g concentration and is the phosphoric acid of 85wt%, 7.6g aluminum isopropoxide, Evenly add 0.96g concentration of 40% hydrofluoric acid, stir until uniform, then add 1.53g 2-methylimidazole (2-MIm), continue stirring until uniform to obtain the reaction precursor reactant, wherein Al 2 o 3 :P 2 o 5 :F - The ratio of :TEAC:2-MIm is 1:1.66:0.53:4.88:0.50 (molar ratio). The above mixture was transferred to a 100ml stainless steel reaction kettle with a polytetrafluoroethylene lining, placed in an oven at 180°C, and kept for 4 hours, then the reaction mixture was cooled to room temperature, 150ml of deionized water was added, stirred, and ultrasonically washed. The reactant was filtered to obtain a white solid powder, which was washed three times repeatedly, and the white powder was washed with 50 ml of acetone....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com