Preparation method of hierarchical pore AFI structured aluminum phosphate molecular sieve

An aluminum phosphate molecular sieve and multi-stage pore technology, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, can solve the problems of imperfect preparation methods of multi-stage pore molecular sieves, long crystallization time of molecular sieves, etc., and achieve The effect of low synthesis cost, environmental friendliness, safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

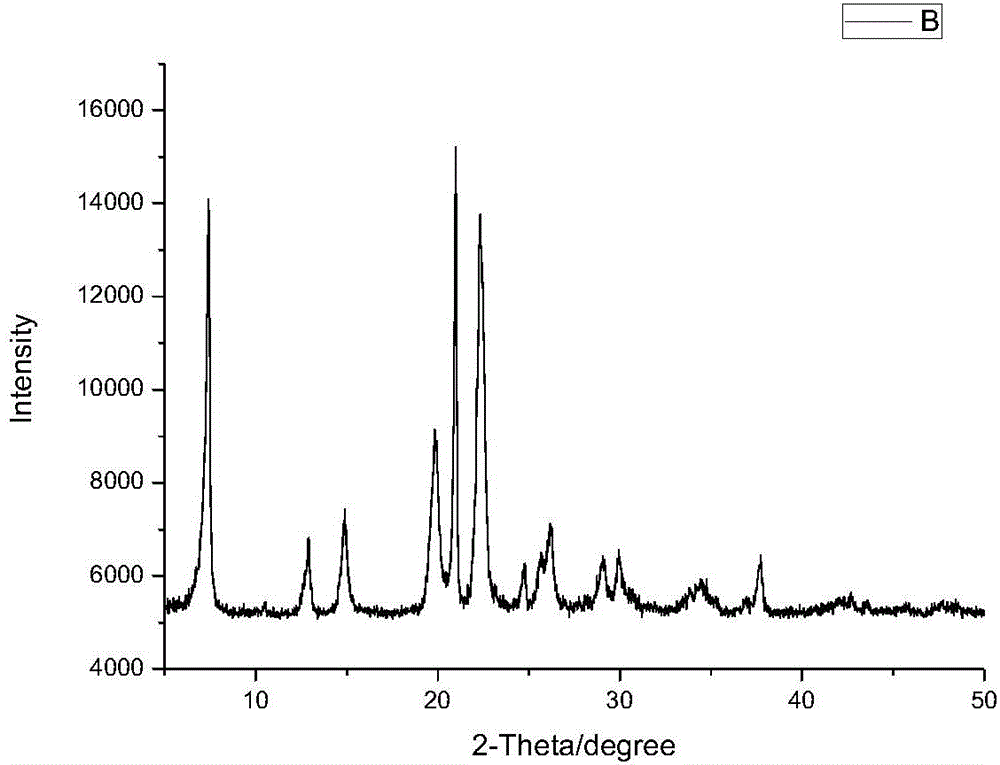

Embodiment 1

[0034]At 90°C, 16.5g of 1-butyl-3-methylimidazolium bromide ionic liquid, 0.44g of aluminum isopropoxide, 0.05g of hydrofluoric acid with a concentration of 40wt%, and 0.75g of phosphoric acid with a concentration of 85wt% were mixed, 0.5 g of n-propylamine was stirred until uniform to obtain a pre-reaction mixture. The reaction mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and then placed in a 150°C oven for crystallization. After 10 hours of crystallization, the reaction kettle was cooled, and then 150ml of deionized water was added to the reaction mixture. Stir, ultrasonically wash, filter the reactant to obtain a white solid powder, repeat the washing three times, and wash the white powder with 50ml of ethanol. The final white powder was dried in an oven at 110°C, and it was confirmed by XRD test that the white powder was the original powder of aluminum phosphate molecular sieve with AFI structure. The moisture and solv...

Embodiment 2

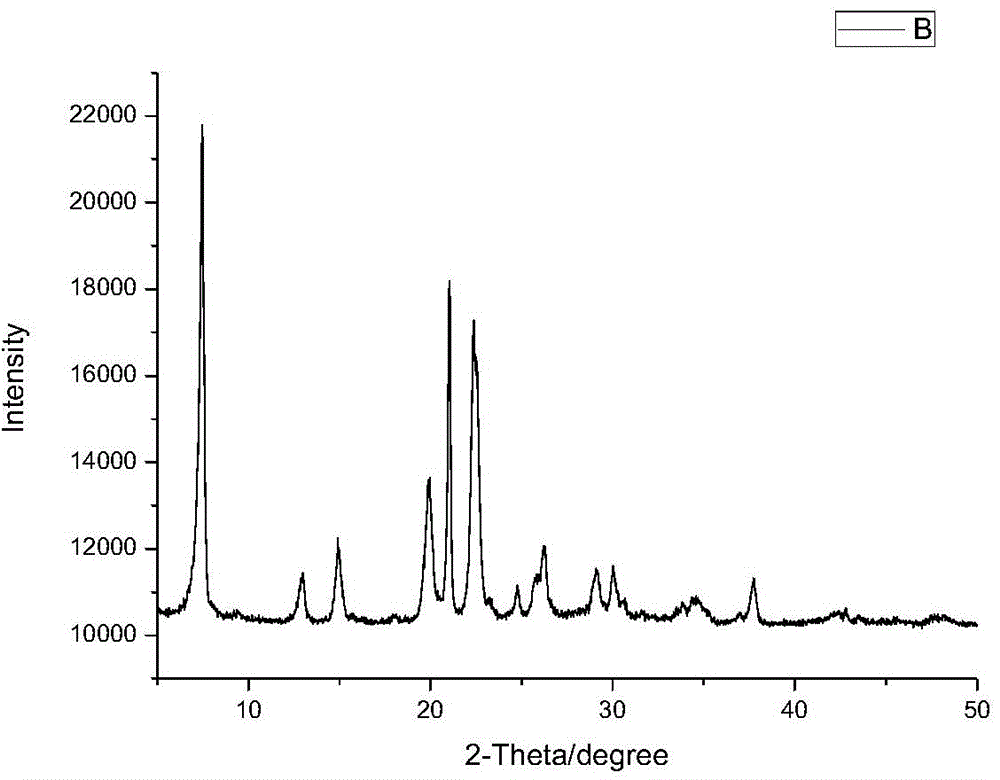

[0036] At 80°C, 33g of 1-butyl-3-methylimidazolium bromide ionic liquid, 0.88g of aluminum isopropoxide, 1.5g of phosphoric acid with a concentration of 85wt%, 0.05g of hydrofluoric acid with a concentration of 40wt%, and 0.4g Ethanolamine was mixed and stirred until uniform to obtain a pre-reaction mixture. The reaction mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene lining, and then placed in a 150°C oven for crystallization. After crystallization for 6 hours, it was taken out, the reaction kettle was cooled, and then 200ml of deionized water was added to the reaction mixture. Ultrasonic washing was performed, and the reactant was filtered to obtain a white solid powder. The washing was repeated three times, and the white powder was washed with 50 ml of ethanol. The final white powder was dried in an oven at 110°C. It was determined by XRD that the white powder was the original powder of aluminum phosphate molecular sieve with AFI ...

Embodiment 3

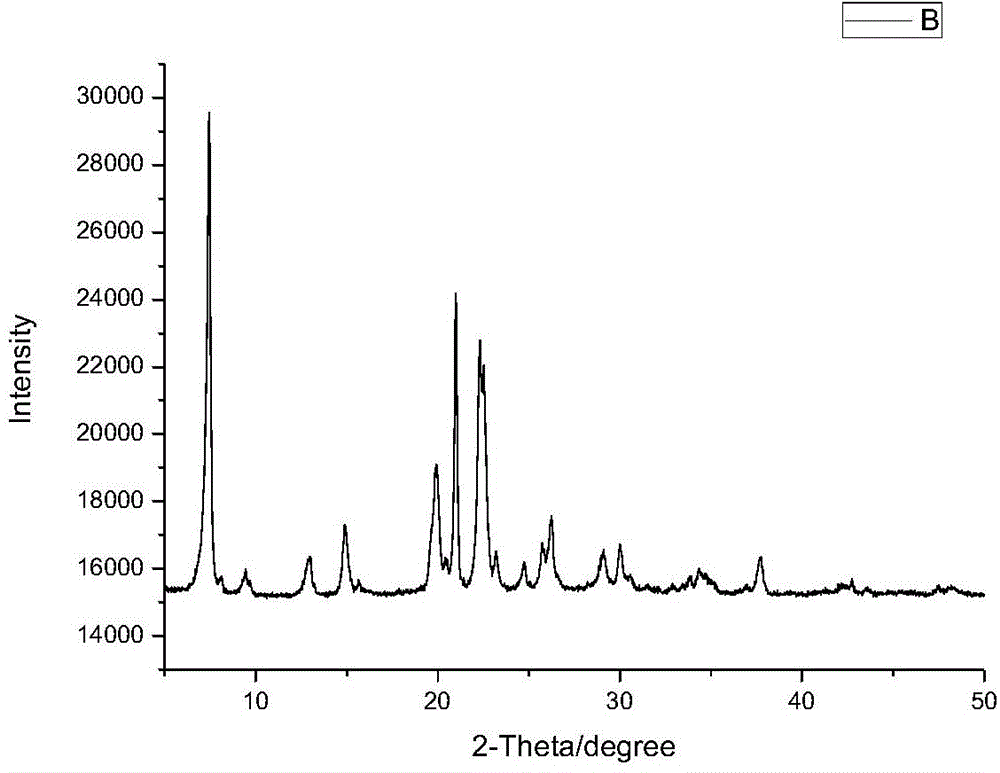

[0038] At 80°C, 20g of 1-butyl-3-methylimidazolium bromide ionic liquid, 1.0g of aluminum isopropoxide, 1.8g of phosphoric acid with a concentration of 85wt%, 0.05g of hydrofluoric acid with a concentration of 40wt%, and 0.5g Ethanolamine was mixed and stirred until uniform to obtain a pre-reaction mixture. The reaction mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and then placed in a 160°C oven for crystallization. After crystallization for 4 hours, the reaction kettle was cooled, and then 300ml of deionized water was added to the reaction mixture. Ultrasonic washing was performed, and the reactant was filtered to obtain a white solid powder. The washing was repeated three times, and the white powder was washed with 50 ml of ethanol. The final white powder was dried in an oven at 110°C. It was confirmed by XRD test that the white powder was the original powder of magnesium aluminum phosphate molecular sieve with AFI struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com