Synthetic process of SAPO-11 Molecular sieve

A technique for the synthesis of SAPO-11, which is applied in the field of synthesis of SAPO-11 molecular sieves, can solve the problems of difficult operation, complex process, and high synthesis cost, and achieve the effects of safe and convenient operation, strong process economy, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

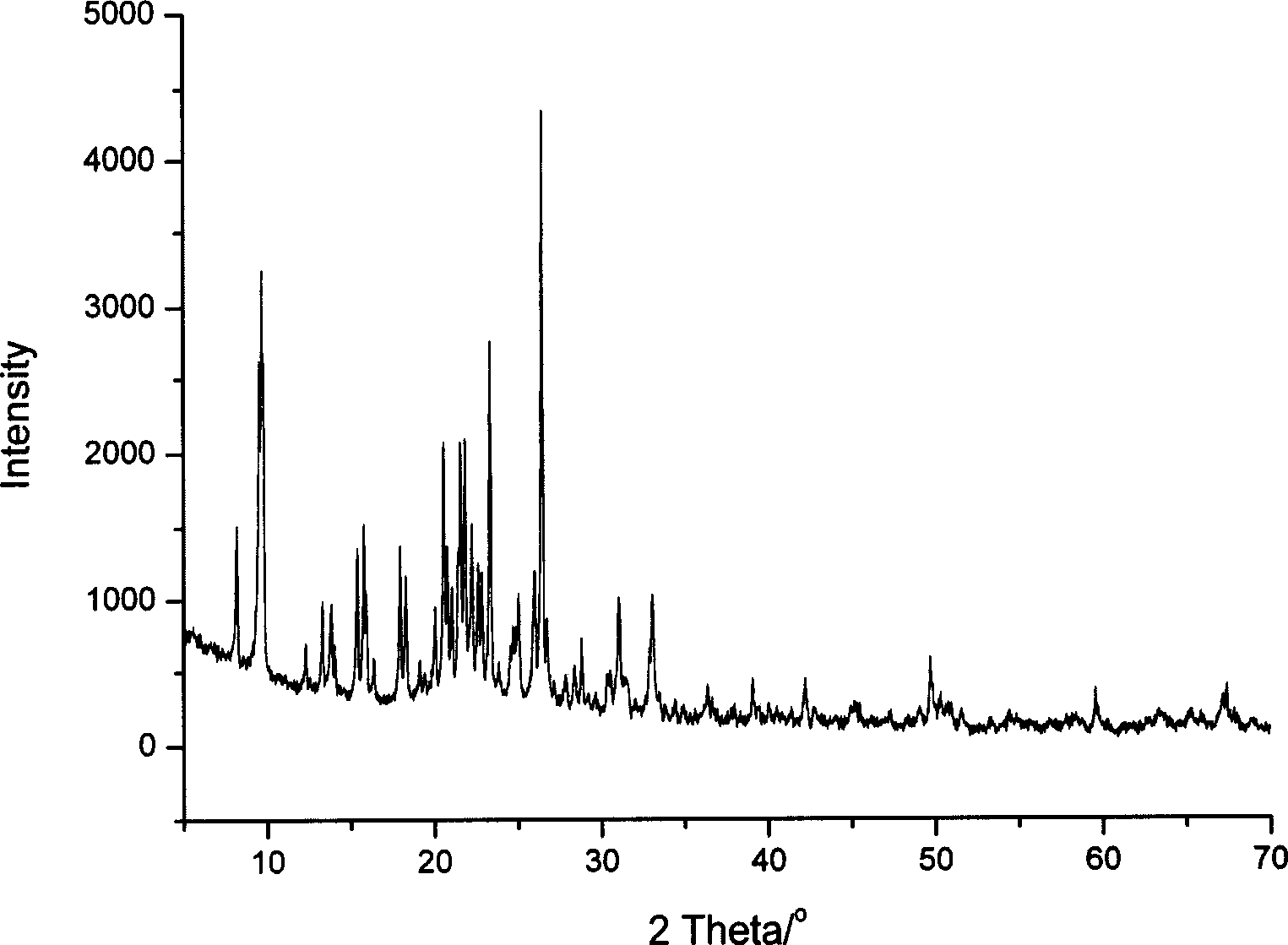

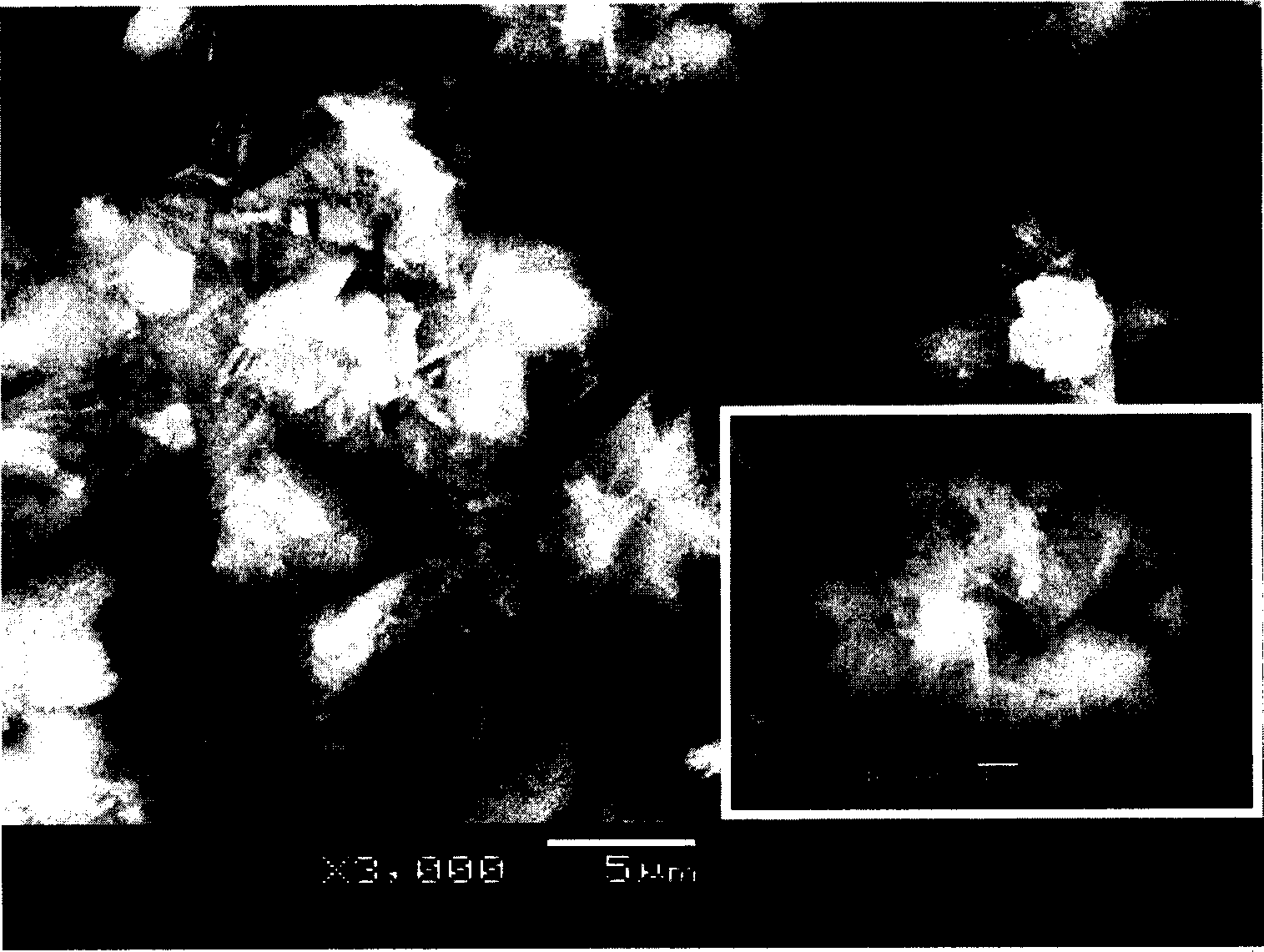

Embodiment 1

[0022] Add 80g of 1-ethyl-3-methylimidazole bromide into a three-necked flask, heat up to 100°C, add 3.2g of phosphoric acid with a concentration of 85wt%, stir well, then add 2.1g of aluminum isopropoxide, stir well, Then add 0.5g ethyl orthosilicate, stir evenly, then add 0.3g hydrofluoric acid with a concentration of 40wt%, stir evenly, heat up to 150°C, keep for 68 hours, then cool the reaction mixture to room temperature, add 150ml water, stir uniform, then the reaction mixture was filtered to obtain a brown powder, which was washed with 100ml of acetone to obtain a white powder, which was tested by XRD to be SAPO-11 molecular sieve and contained a small amount of unknown miscellaneous crystals. The water in the washed filtrate and the solvent for washing the molecular sieves are evaporated in a rotary evaporator to recover the ionic liquid.

Embodiment 2

[0024] Add 200g of 1-ethyl-3-methylimidazole bromide into a three-necked flask, heat up to 80°C, add 3.2g of phosphoric acid with a concentration of 85wt%, stir well, then add 2.1g of aluminum isopropoxide, stir well, Then add 0.5g ethyl orthosilicate, stir evenly, then add 0.3g hydrofluoric acid with a concentration of 40wt%, stir evenly, heat up to 150°C, keep for 68 hours, then cool the reaction mixture to room temperature, add 150ml water, stir uniform, then the reaction mixture was filtered to obtain a brown powder, which was washed with 100ml of acetone to obtain a white powder, which was tested by XRD to be SAPO-11 molecular sieve and contained a small amount of unknown miscellaneous crystals.

Embodiment 3

[0026] Add 40g of 1-ethyl-3-methylimidazole bromide into a three-necked flask, heat up to 150°C, add 3.2g of phosphoric acid with a concentration of 85wt%, stir well, then add 2.1g of aluminum isopropoxide, stir well, Then add 0.5g ethyl orthosilicate, stir evenly, then add 0.3g hydrofluoric acid with a concentration of 40wt%, stir evenly, heat up to 150°C, keep for 68 hours, then cool the reaction mixture to room temperature, add 150ml water, stir uniform, then the reaction mixture was filtered to obtain a brown powder, which was washed with 100ml of acetone to obtain a white powder, which was tested by XRD to be SAPO-11 molecular sieve and contained a small amount of unknown miscellaneous crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com