Activation method of carbon fiber electrode material using polyacrylonitrile carbon fiber

A technology of polyacrylonitrile carbon fiber and carbon fiber electrode, which is applied in the direction of carbon fiber, fiber treatment, textiles and paper making, and can solve the problem of limited electrochemical activity of carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0013] Industrial polyacrylonitrile carbon fiber carbonized at about 1300°C, with a concentration of no more than 0.6%

[0014] After impregnating the carbon fiber woven cloth in the acetone solution of cyclocyanide resin for 1-5 minutes, heat up to 630°C under the condition of 60-0mmHg low vacuum, put in 1 atm air, and then evacuate, repeat 10 times, the temperature is naturally at 630- Fluctuate within 780'C, after about 40 minutes, cool down naturally. After treatment, the surface properties of carbon fibers are improved, as shown in Table I data. Increased electrode activity

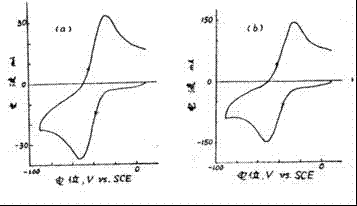

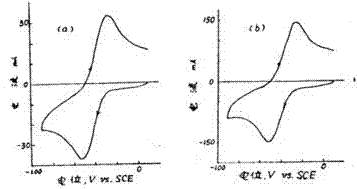

[0015] More than 3 times, as shown in Figure l.

Embodiment 2

[0017] Industrially, polyacrylonitrile carbon fiber carbonized at about 1300°C is impregnated with carbon fiber woven cloth for 1-5 minutes in acetone solution of epoxy resin with a concentration of no more than 0.5%, and the temperature is raised to 60-0mmHg under low vacuum conditions. 600°C, put in 300-400mmHg air, then evacuate, repeat 8 times, the temperature will naturally fluctuate within 600-714°C, after about 30 minutes, cool down naturally. The surface properties of the treated carbon fiber are improved, and the electrode activity is increased by more than 3 times, as shown in Figure 1.

Embodiment 3

[0019] In the industry, polyacrylonitrile carbon fiber carbonized at about 1300 ℃, in the epoxy resin acetone solution with a concentration of no more than 0.5%, the carbon fiber woven cloth after impregnation treatment for 1-5 minutes is under the low vacuum condition of 60-0 mmHg, Raise the temperature to 660°C and put in 300-500 mmHg air, then pump it out and repeat it 8 times. The temperature will naturally fluctuate within 550-680°C. After about 20 minutes, it will cool down naturally. The surface properties of the treated carbon fiber are improved, and the electrode activity is increased by 3 times as shown in Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com