Interior material for motor vehicles

A technology for interior decoration and automobiles, applied to vehicle parts, transportation and packaging, and special positions of vehicles, etc., can solve problems such as through-hole clogging, achieve the effects of preventing global warming, excellent sound absorption, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

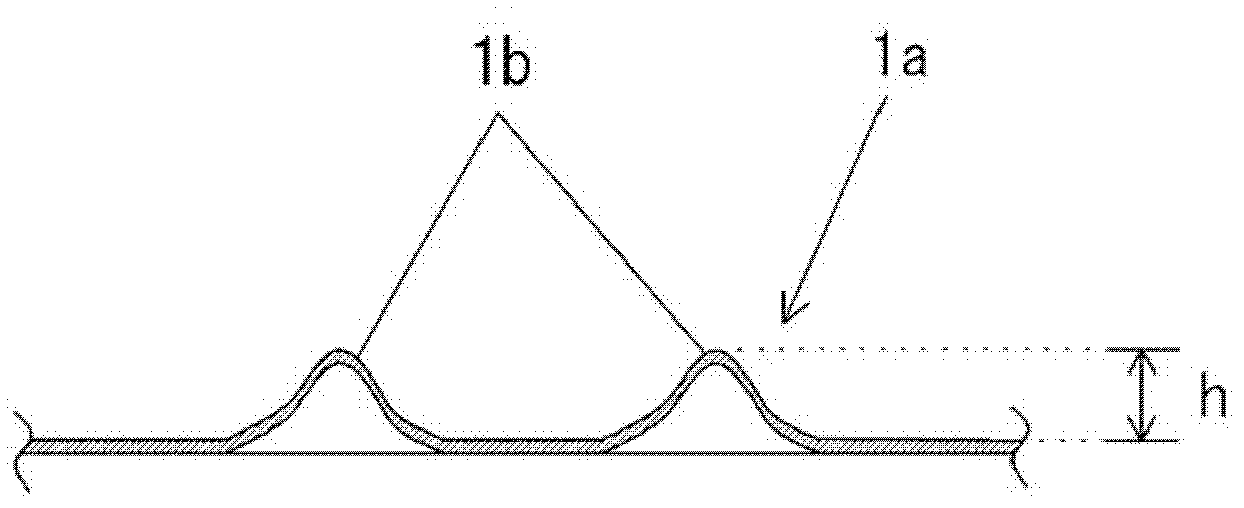

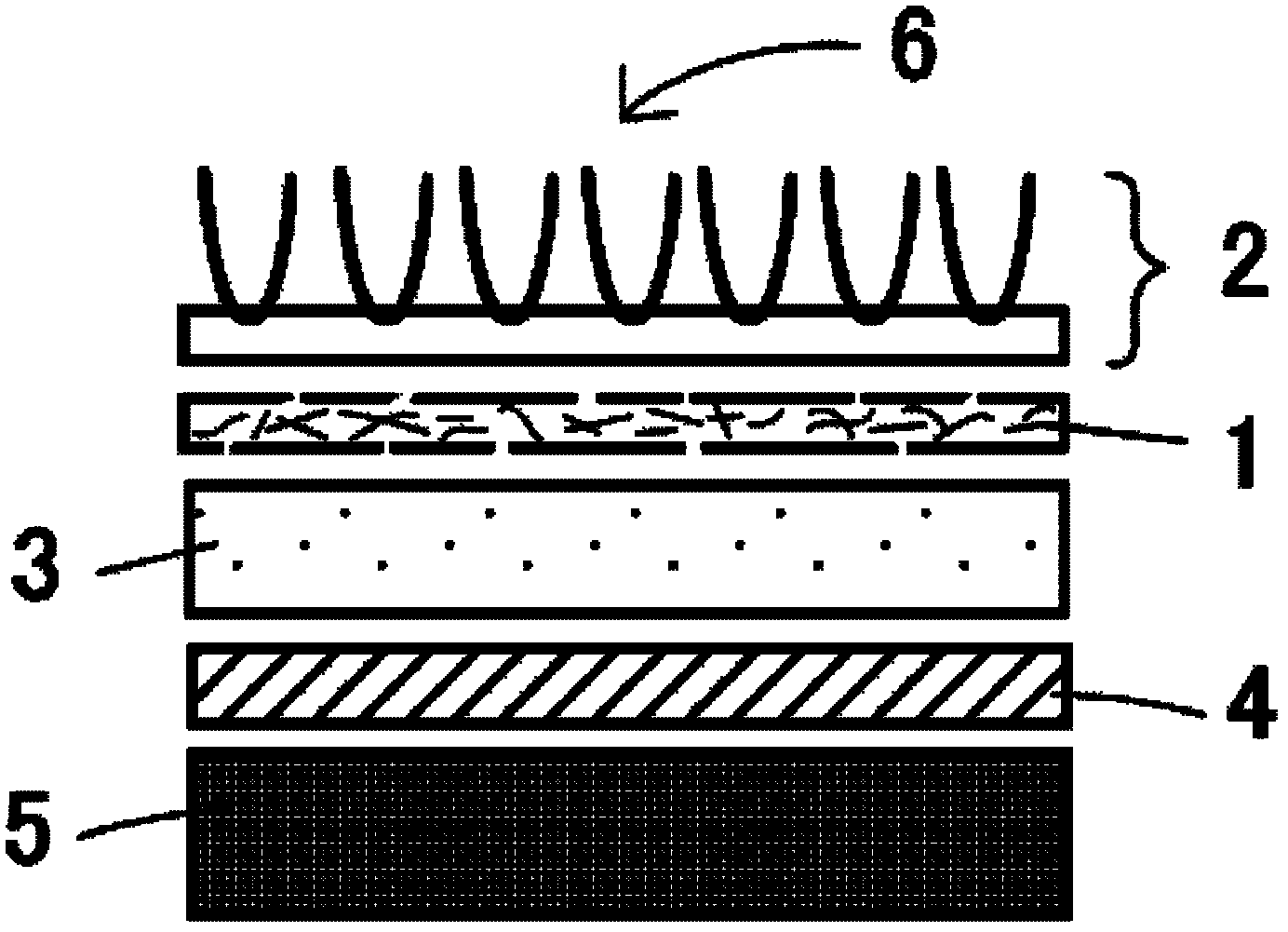

[0133] The weight per unit area made of polyester fiber is 120g / m 2 , a breathable surface material of needle-punched non-woven fabric with a thickness of 3mm.

[0134] Next, wood pulp composed of 50% by mass of softwood pulp and 50% by mass of broadleaf tree pulp is used as a raw material, and the beating degree reaches JIS P 8121-1995 4. Canadian standard with a disk refiner. The Canadian Standard Freeness 490ml (CSF) stipulated by the Canadian Standard Freeness is beaten, and then made through the usual papermaking process. The wrinkle rate is 25%, and the mass per unit area is 30g / m 2 , a paper material made of porous pulp fibers with an air resistance of 0.84kPa·s / m.

[0135] 3g / m on one side of the above paper material 2After coating hot-melt adhesive powder composed of polyester resin with a melting point of 150 °C and a particle size of 200 μm to 300 μm, the above-mentioned air-permeable surface material is laminated on the coated surface, and the paper is removed fr...

Embodiment 2

[0143] Except that the mass per unit area of the formable felt in Example 1 is set to 150g / m 2 Other than that, the thickness is 26.0mm and the weight is 1206g / m by the same method 2 interior material (No.2).

[0144] In addition, the airflow resistance of the moldable felt at this time was 0.04 kPa·s / m. And in the same manner as in Example 1, (air-permeable surface material-paper material)-formable felt is sequentially laminated, which is laminated and bonded through heating-cooling, and its air resistance is 1.27kPa·s / m.

Embodiment 3

[0146] Except that the mass per unit area of the formable felt in Example 1 is set to 100g / m 2 Other than that, the thickness is 26.0mm and the weight is 1156g / m by the same method 2 interior materials (No.3).

[0147] In addition, the airflow resistance of the moldable felt at this time was 0.03 kPa·s / m. And in the same manner as in Example 1, (air-permeable surface material-paper material)-formable felt is sequentially laminated, which is laminated and bonded through heating-cooling, and its air resistance is 1.26kPa·s / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com