Zener diode protection network in submount for leds connected in series

A zener diode and light emitting diode technology, which is applied in the use of semiconductor lamps, electrical components, circuits, etc., can solve the problems of insufficient surface area of zener diode silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

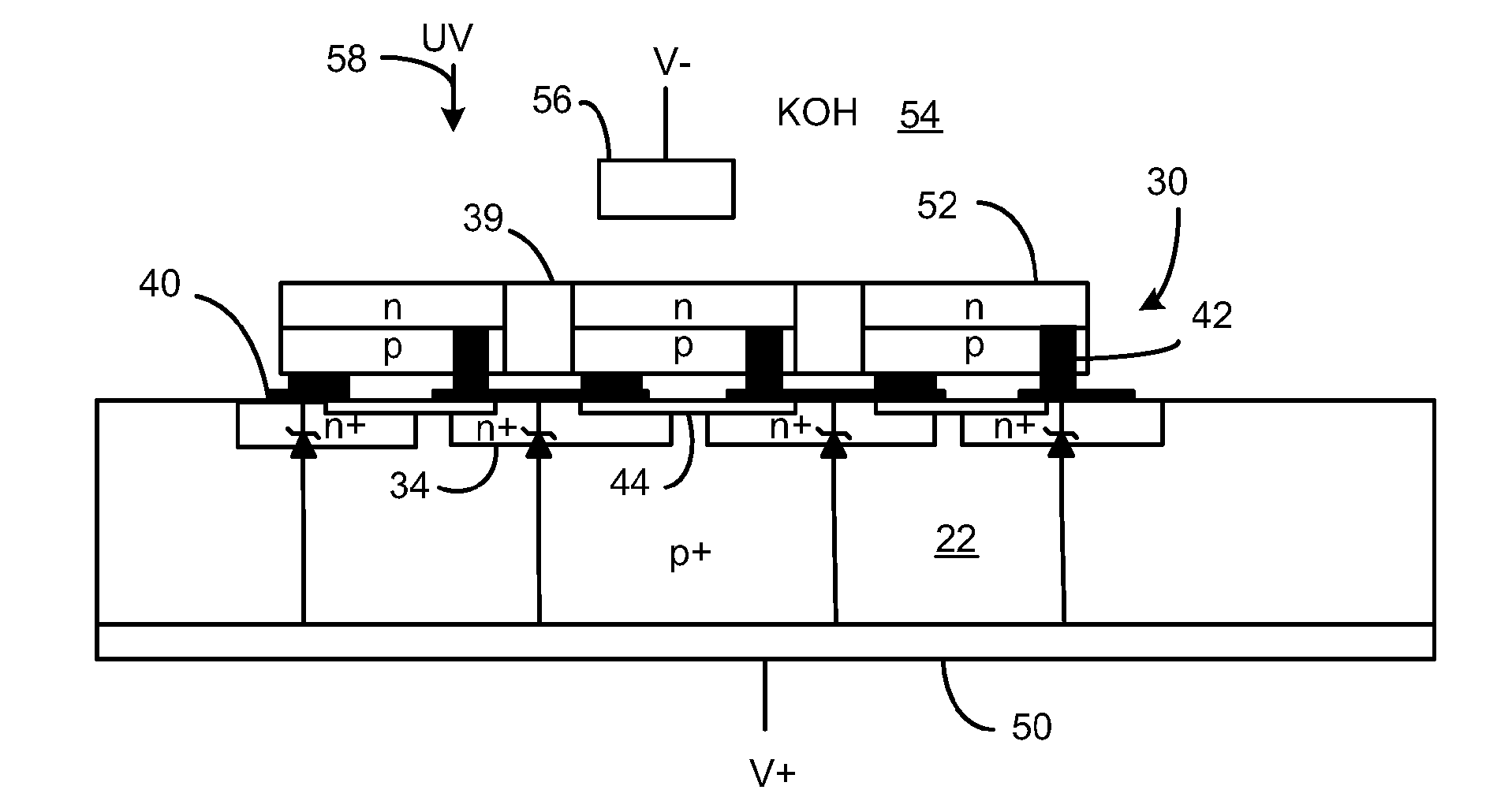

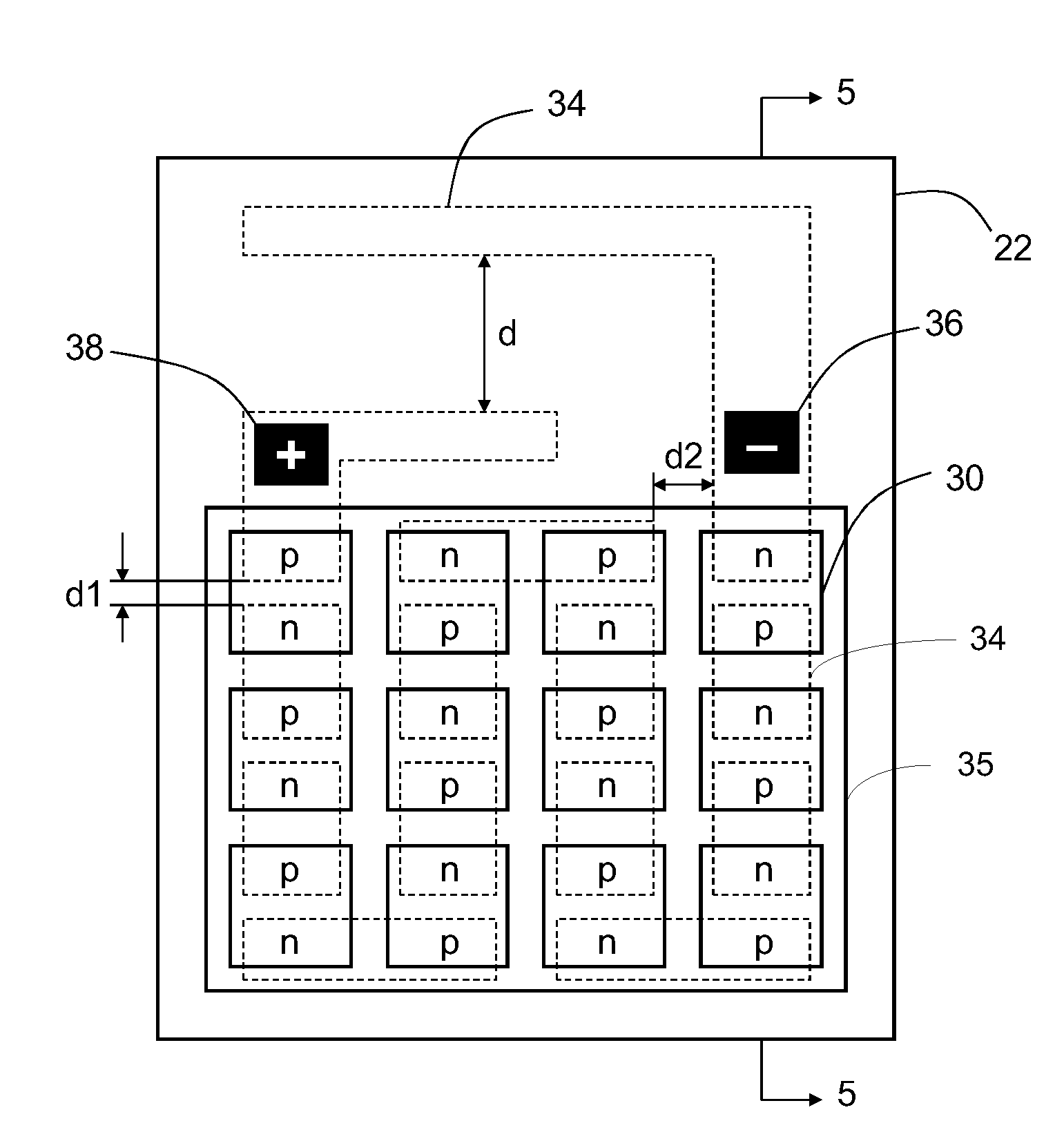

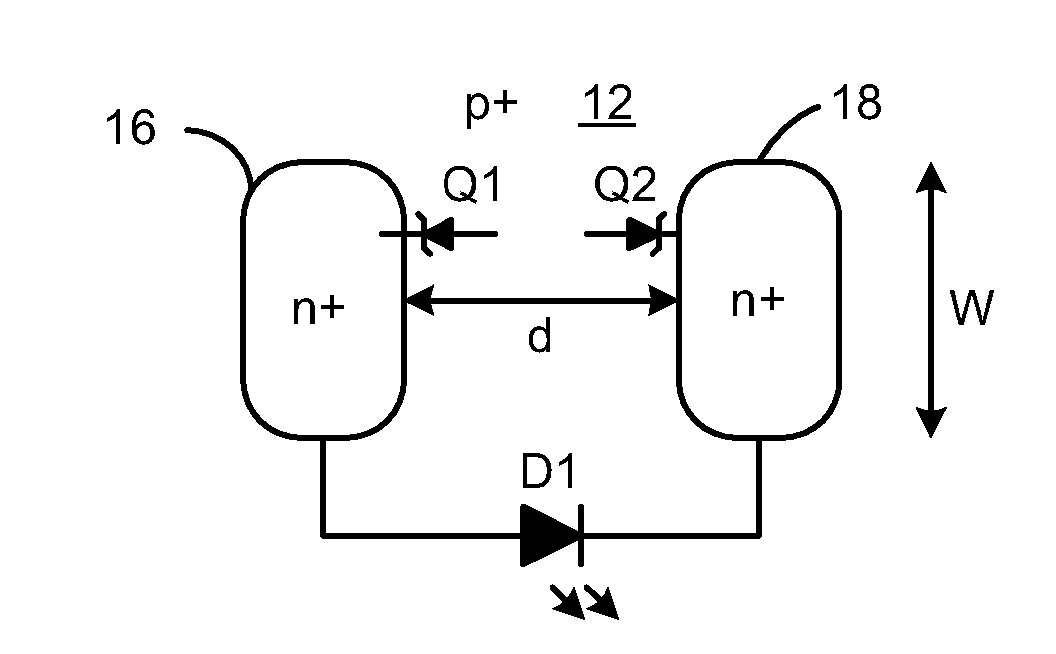

[0027] As a preliminary matter, LEDs were formed on a growth substrate. In the example used, the LEDs are GaN-based LEDs, such as AlInGaN or InGaN LEDs, which are used to generate UV by green light. Typically, a relatively thick n-type GaN layer is grown on a sapphire growth substrate using conventional techniques. Relatively thick GaN layers typically include a low temperature nucleation layer and one or more additional layers to provide a low defect lattice structure for the n-type cladding layer and active layer. Then, one or more n-type cladding layers are formed over the thick n-type layer, followed by the active layer, one or more p-type cladding layers, and a p-type contact layer (for metallization).

[0028] For flip-chip, portions of the p-layer and active layer are etched away to expose the n-layer for metallization. In this way, the p-contact and n-contact are on the same side of the chip and can be electrically attached directly to the substrate contact pads. Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com