High-voltage transient voltage suppressor chip and production process

A technology of transient voltage suppression and production technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve problems such as poor anti-surge capability, affect product reliability, chip damage, etc., and improve withstand voltage performance , Improving the effect of anti-surge capability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

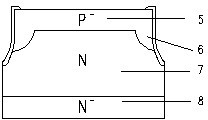

[0036] Such as Figure 1 to Figure 6 As shown, the chip structure of the high-voltage transient voltage suppressor (TVS) is divided into P + NN + Unidirectional High Voltage Transient Voltage Suppressor or P + NP + bi-directional high voltage transient voltage suppressor,

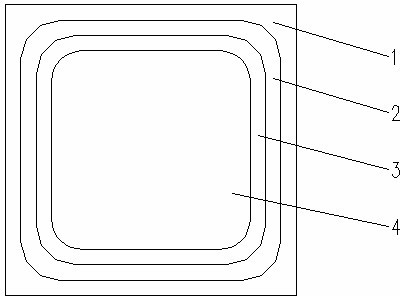

[0037] P + NN + The chip front section of the unidirectional high voltage transient voltage suppressor is as follows: TVS chip 1, mesa groove 2, glass layer 3, metal surface 4;

[0038] P + NP + Bi-directional high-voltage transient voltage suppressor, the front section of the chip is as follows: TVS chip 1, mesa groove 2, glass layer 3, metal surface 4;

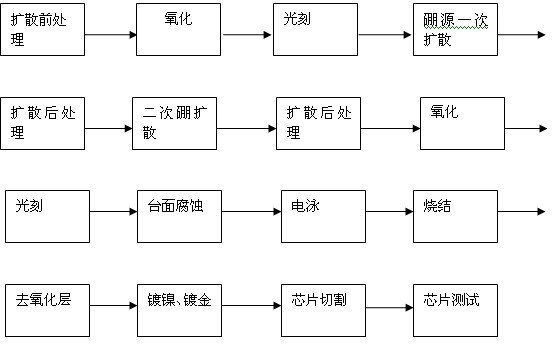

[0039] Such as figure 2 As shown, the chip process flow of the transient voltage suppressor TVS is as follows:

[0040] 1) Pre-diffusion treatment: chemically treat the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com