Belly pipe with pulverized coal burning function

A technology of pulverized coal combustion and straight blowing, which is applied in the direction of tuyere etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

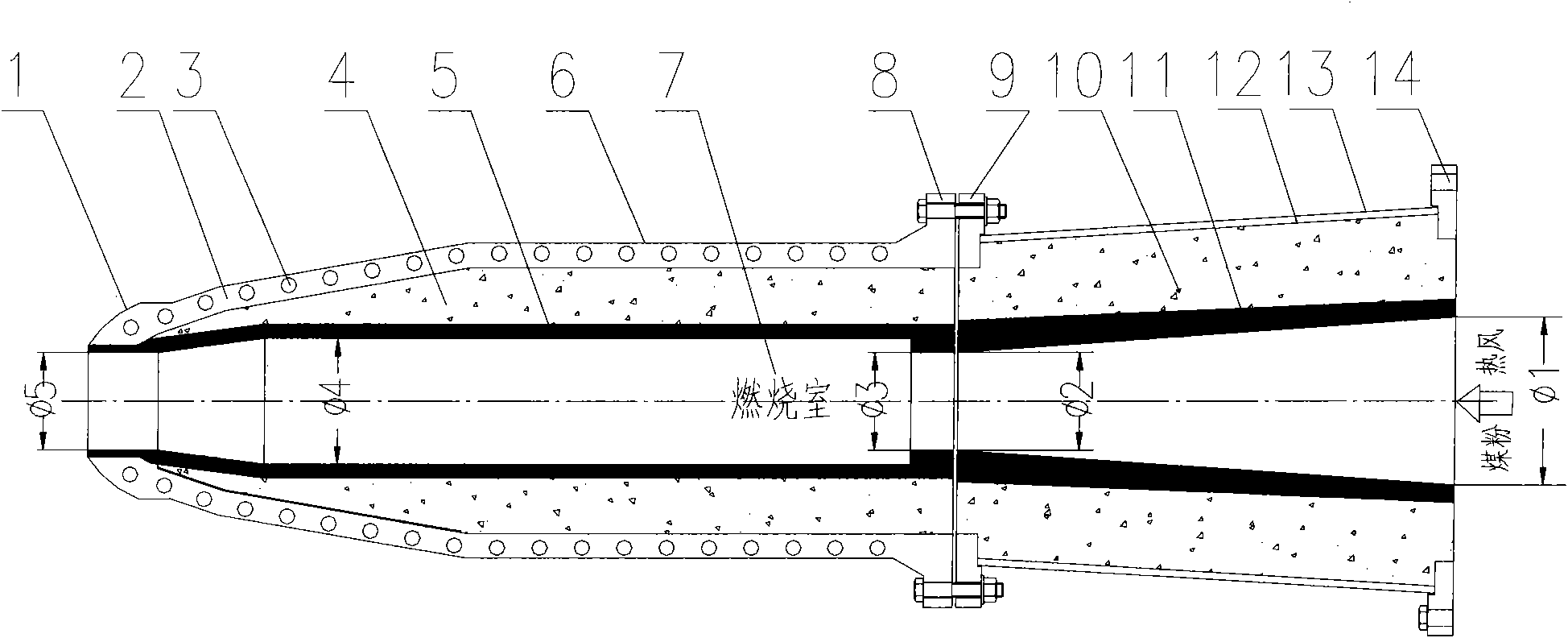

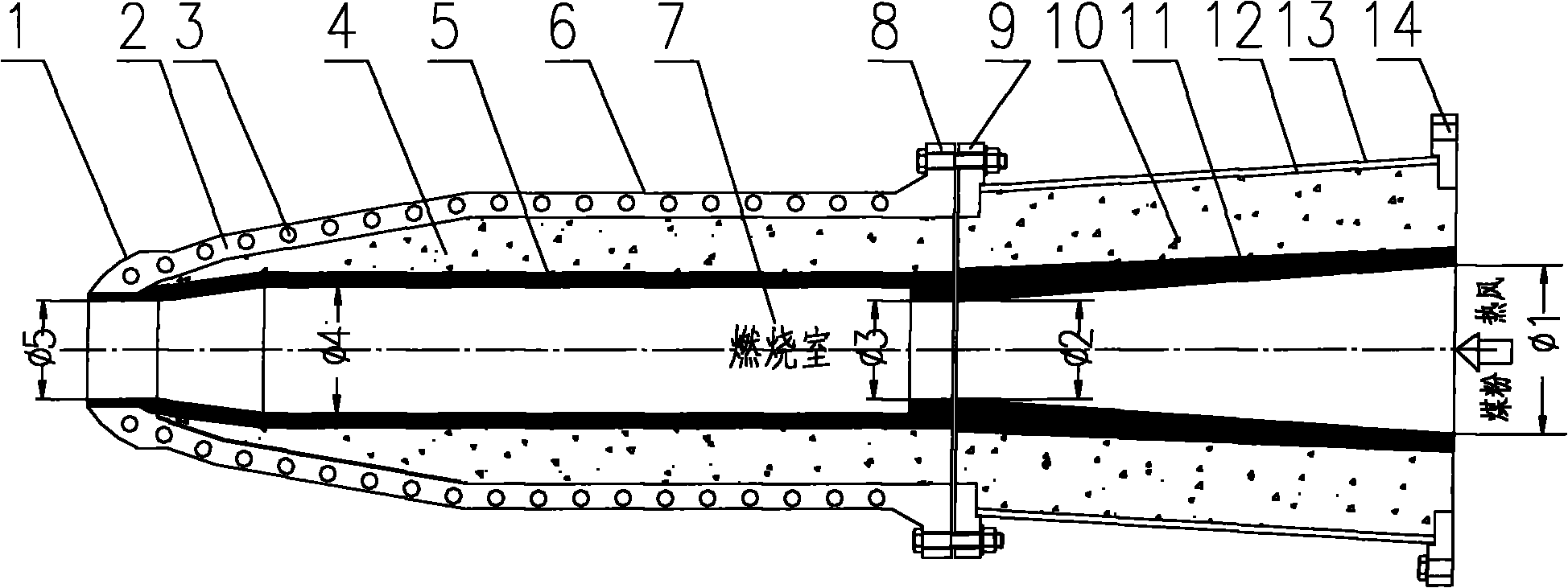

[0021] Such as figure 1 As shown, the straight blowing pipe with pulverized coal combustion function is composed of a burner 6 and a pre-burner 13, and the burner 6 and the pre-burner 12 are connected by flanges 8 and 9, and hot air and pulverized coal are fed from the pre-burner at the same time. Entrance to enter.

[0022] Such as figure 1 As shown, the internal channel of the pre-combustor 6 is a reducer structure, and its function is to accelerate and mix the hot air and coal powder, which is equivalent to the function played by the existing tuyeres. The outlet diameter ¢2 of the preburner 13 is smaller than the inlet diameter ¢1 and equal to the burner inlet diameter ¢3.

[0023] Such as figure 1 As shown, in the burner 6, a combustion chamber 7 with a sudden diameter expansion is provided. Part of the pulverized coal that is mixed and has combustion conditions burns rapidly, just like the similar effect of deceleration and rapid combustion when the existing pulverize...

Embodiment 2

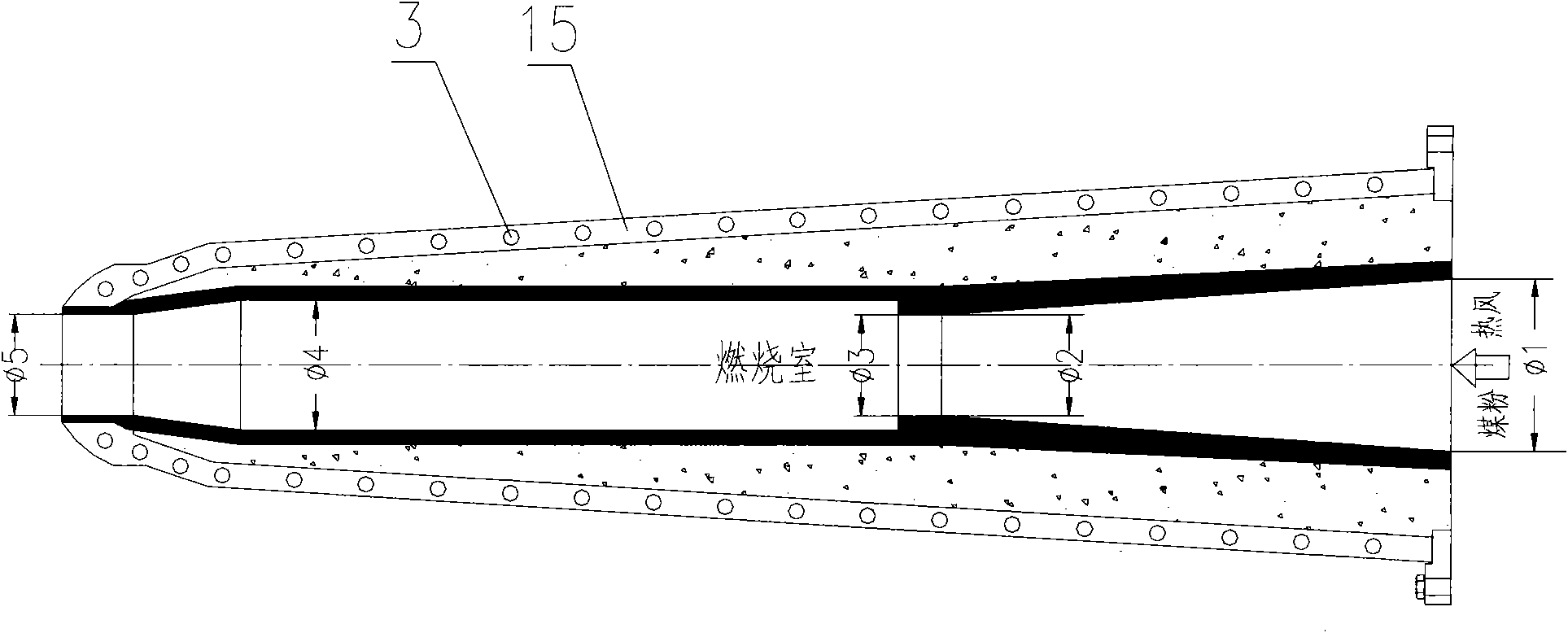

[0030] Such as figure 2 As shown, the above-mentioned burner 6 and pre-combustor 13 can save the intermediate connecting flanges 8 and 9 when it is convenient to manufacture, and make them into a whole, and their internal structure remains unchanged. At this time, the integral housing 15 has a cooling water channel 3 inside. The material of the housing 2 is heat-resistant stainless steel or copper or a combination of other metal materials.

[0031] In the above description, the tuyere and the elbow are the contents of the prior art. Instructions attached figure 1 Attached is the abstract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com