Touch pad sensor

A sensor and touch panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve problems such as inability to ensure electrical conductivity, and achieve difficult resistance increase, high reliability, and excellent durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

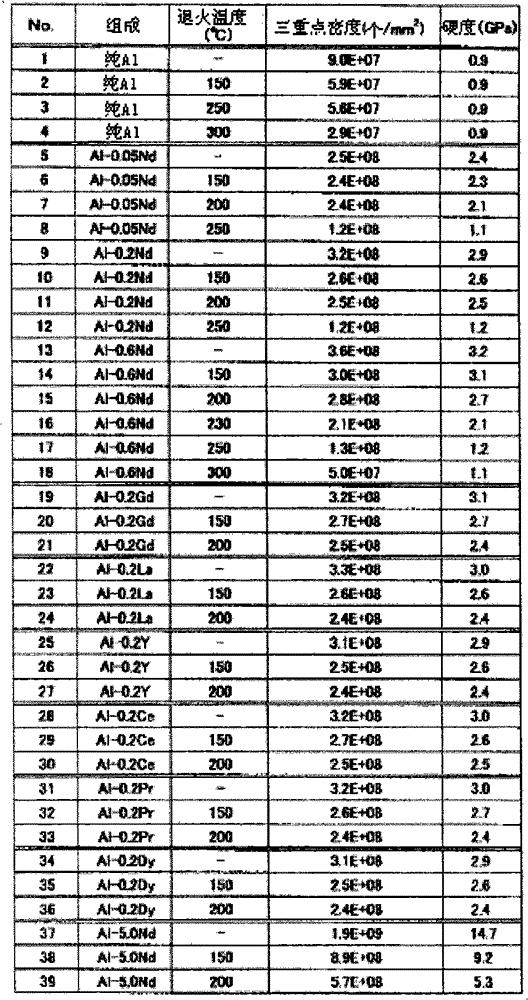

[0032] With an alkali-free glass plate (thickness 0.7mm, diameter 4 inches) as the substrate, the types and contents of the rare earth elements shown in Table 1 below are formed on its surface by DC magnetic sputtering (the unit is atomic %, and the balance: Al and unavoidable impurities) different Al alloy films (both film thicknesses are about 500 nm). Make the atmosphere in the chamber reach vacuum degree before film formation: 3×10 -6 Torr, using a disc-shaped target with a diameter of 4 inches having the same composition as that of each Al alloy film, film formation was carried out under the following conditions. Next, the Al alloy after film formation was heat-treated at various annealing temperatures listed in Table 1 for 30 minutes in a nitrogen atmosphere. In Table 1, "-" means no heating (ie, room temperature). In addition, the composition of the formed Al alloy film was confirmed by an Inductively Coupled Plasma (ICP) mass spectrometry.

[0033] (sputtering condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com