High temperature resistant flexible deintercalating/removing and signal transmission long line cable used for aerospace

A signal transmission, high-temperature flexible technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of reducing the reliability of cable performance, poor cable flexibility, and easy to be scratched, so as to achieve the goal of not being easily scratched, Superior low temperature resistance and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

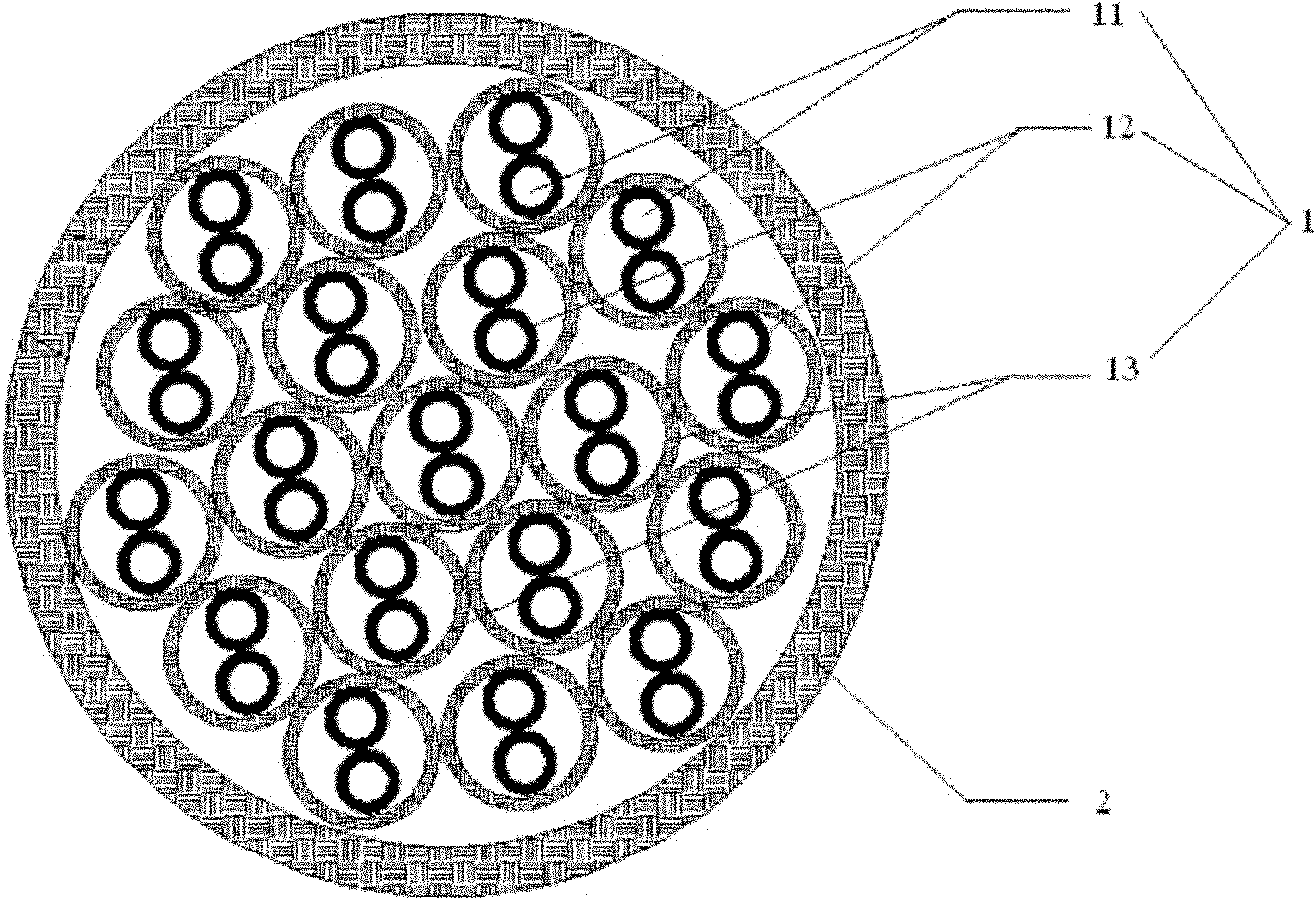

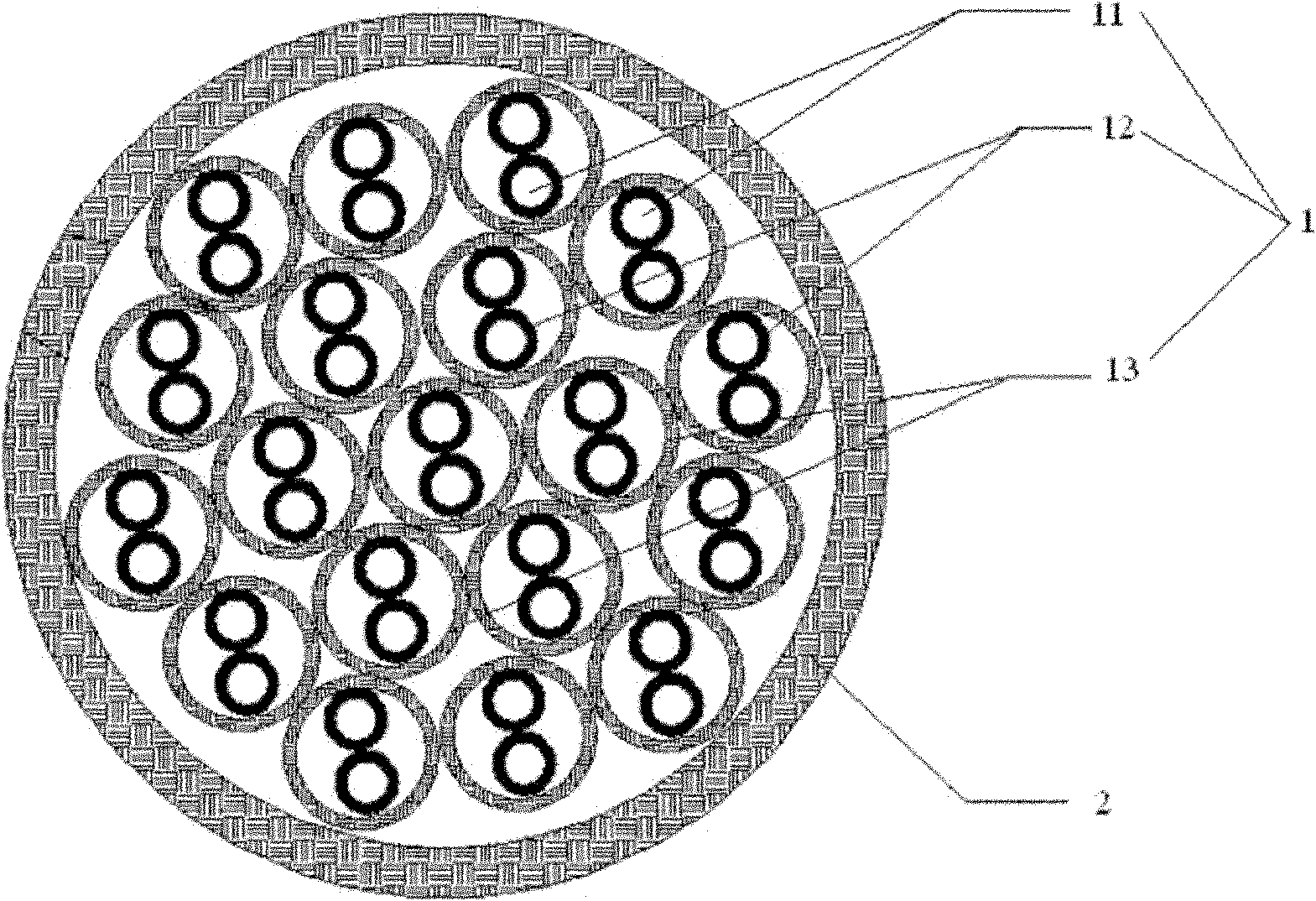

[0031] High temperature resistant flexible plug-in and signal transmission long-line cable for aerospace with 38 cores, such as figure 1 As shown, it includes a cable core and an outer sheath layer 2 wrapped outside the cable core. The cable core includes 19 groups of inner cores 1, and each group of inner cores 1 includes two mutually twisted insulated wire cores and is wrapped in two The metal shielding layer 13 outside the two twisted insulated wire cores, the insulated wire core includes a conductor 11 and an insulating layer 12 wrapped outside the conductor 11; the outer sheath layer 2 is a high temperature resistant fiber braided layer.

[0032] The preparation of the high-temperature-resistant flexible detachment and signal transmission long-line cable for aerospace with an inner core of 38 cores includes the following steps:

[0033] 1) Use 19 / 0.18mm silver-plated copper stranded wires to form a round silver-plated copper stranded conductor through concentric stranding...

Embodiment 2

[0040] The preparation of a high-temperature-resistant flexible detachment and signal transmission long-line cable for aerospace use with an inner core of 50 cores includes the following steps:

[0041] 1) Use 19 / 0.18mm silver-plated copper stranded wires to form a round silver-plated copper stranded conductor through concentric stranding; among them, the stranding pitch is 16D (D is the outer diameter of the silver-plated copper stranded conductor) , the outer diameter of the silver-plated copper stranded conductor is 0.90mm;

[0042] 2) Using a high-temperature extruder outside the silver-plated copper stranded conductor to form an insulating layer through the extrusion process of granular or massive high-temperature-resistant insulating materials to obtain an insulated wire core, wherein the thickness of the insulating layer is 0.25mm , the outer diameter of the insulated wire core is 1.40±0.05mm;

[0043] 3) Twisting two insulated wire cores of blue and transparent color ...

Embodiment 3

[0048] The preparation of the high-temperature-resistant flexible detachment and signal transmission long-line cable for aerospace with a 28-core inner core includes the following steps:

[0049] 1) Use 19 / 0.18mm silver-plated copper stranded wires to form a round silver-plated copper stranded conductor through concentric stranding; among them, the stranding pitch is 16D (D is the outer diameter of the silver-plated copper stranded conductor) , the outer diameter of the silver-plated copper stranded conductor is 0.90mm;

[0050] 2), outside the silver-plated copper stranded conductor, use a high-temperature extruder to form an insulating layer through the extrusion process of the granular high-temperature-resistant insulating material to obtain an insulating wire core, wherein the thickness of the insulating layer is 1.0mm, and the The outer diameter of the insulated wire core is 2.90±0.10mm;

[0051] 3) Twisting two insulated wire cores of blue and transparent color respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com