Combined technology of phosphorite scrubbing and direct floatation and reverse floatation

A forward and reverse flotation, combined process technology, applied in the direction of flotation, wet separation, filtration loop, etc., can solve the problems of increasing the coverage of fertile fields, loss of resources, silting river channels, etc., to improve the utilization rate of backwater, reduce The cost of beneficiation and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

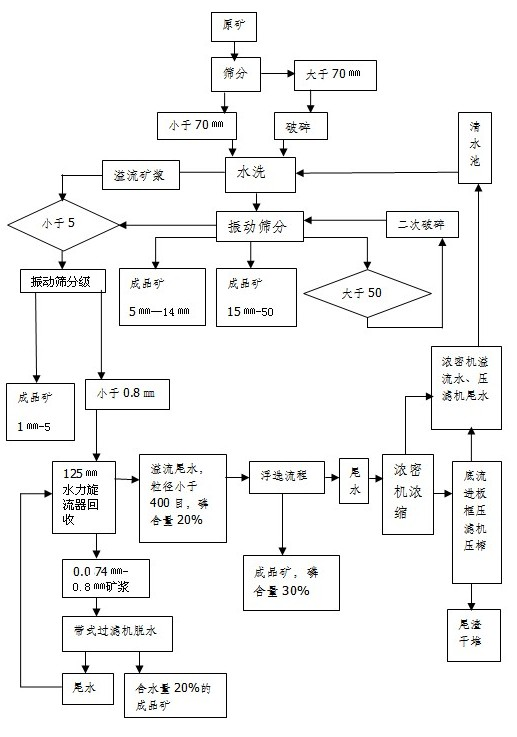

[0018] The combined process of phosphate rock scrubbing and positive and negative flotation is as follows: (such as figure 1 shown)

[0019] 1. The raw ore enters the first stage of screening from the hopper, and the raw ore larger than 70mm enters the first stage of crushing to 65mm and then enters the ore washing machine, and the raw ore smaller than 70mm is directly used as the screen material to the ore washing machine;

[0020] 2. The ore is scrubbed in the ore washing machine to achieve the first desliming, and the scrubbed ore enters the second stage of screening;

[0021] 3. a. The output of the ore washing machine enters the second stage of screening and desliming to produce finished ore of 5㎜-14㎜, 15㎜-50㎜;

[0022] b. Lump ore larger than 50mm after screening enters the secondary crushing, and then returns to the second stage of screening and classification;

[0023] c. The overflow ore pulp at the tail of the ore washing machine and the underflow ore pulp (less th...

Embodiment 2

[0029] 1-5, 7 steps are identical with embodiment 1.

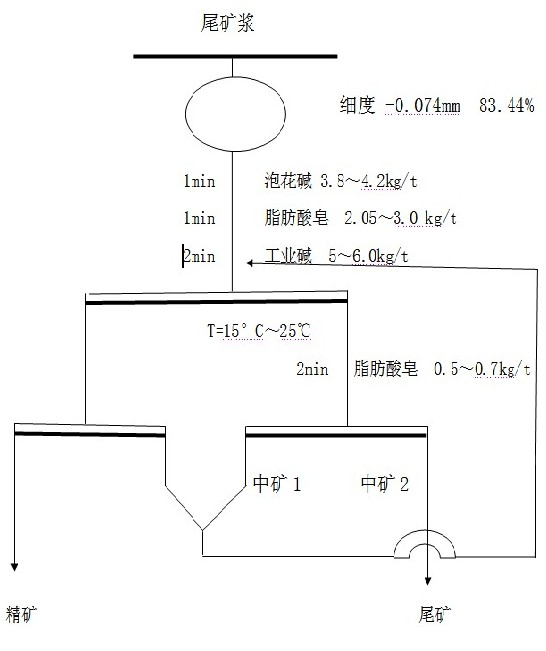

[0030] 6. When the tailings fineness is 0.074㎜, it accounts for 83.44%, and the pulp concentration is 23 ~ In the case of 24%, adopt the beneficiation process of positive flotation (one coarse, one fine and one sweep), and the dosage of positive flotation roughing agent is: 4.0kg / t of inhibitor natron, 2.05kg / t of collector fatty acid soap t, adjusting agent industrial alkali 6.0kg / t, adding collector fatty acid soap 0.5kg / t in the scavenging process, flotation temperature is 20 ℃, the grade of obtained phosphorus concentrate is 30.83%, the recovery rate is 84.43%, the yield 69.10% beneficiation index.

Embodiment 3

[0032] 1-5, 7 steps are identical with embodiment 1.

[0033] 6. When the tailings fineness is 0.074㎜, it accounts for 83.44%, and the pulp concentration is 23 ~ In the case of 24%, the beneficiation process of positive flotation-coarse-fine-sweeping is adopted, and the dosage of positive flotation roughing agents is: 4.0 kg / t of inhibitor natron, 3.0 kg / t of collector fatty acid soap, Adjusting agent (industrial alkali) 6.0kg / t, adding collector fatty acid soap 0.5kg / t in the scavenging process, under the condition of flotation temperature of 25℃, the grade of phosphorus concentrate is 30.58%, and the recovery rate is 90.71% , The beneficiation index with a yield of 75.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com