Automatic LED light-splitting and sorting system

A sorting system and automatic sorting technology, which is applied in the electronic field, can solve the problems that LED automatic 100% spectroscopic detection and sorting cannot be realized, and achieve the effects of fast detection speed, guaranteed continuity, and improved detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

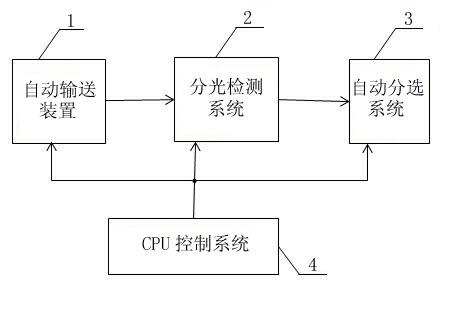

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[0025] A fully automatic LED spectroscopic sorting system, mainly for sorting straw hat-shaped LED lamp beads, including automatic conveying device 1, spectroscopic detection system 2, automatic sorting system 3 and CPU control system 4, automatic conveying device 1 and spectroscopic detection system The system 2 is connected, the spectroscopic detection system 2 is connected with the automatic sorting system 3, the CPU control system 4 is respectively connected with the automatic conveying device 1, the spectroscopic detection system 2, and the automatic sorting system 3, and the spectroscopic detection results are displayed on the display screen 5 in real time Update the display.

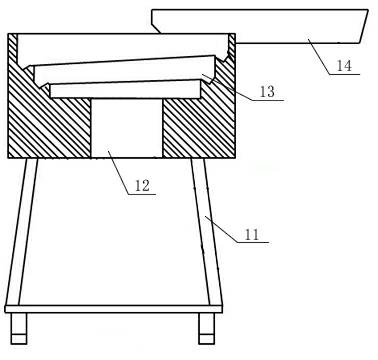

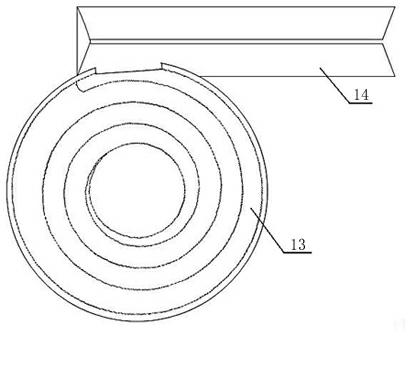

[0026] The automatic conveying device 1 is composed of a vibrating screw conveyor 11, a storage barrel 12, a screw conveying trough 13, a vibrating linear conveyor 14 and an equal interval fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com