Out-wall joint and assembly method thereof for embedded metal hose

A metal hose and hose technology, which is applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of increasing the width and depth of the slot, increasing the difficulty of construction, and increasing the difficulty of installation, etc. Achieve the effect of avoiding erosion, easy installation of buried walls, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

Embodiment

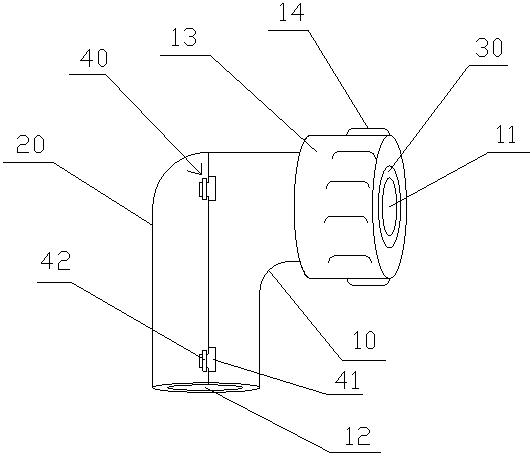

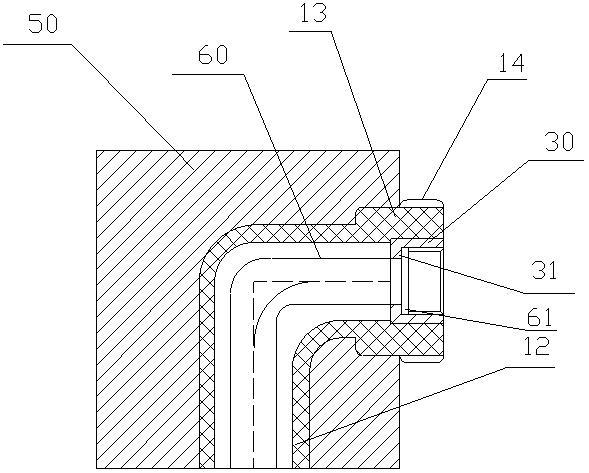

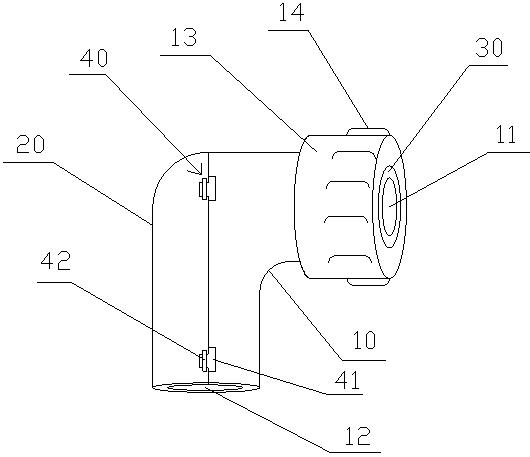

[0028] see figure 1 and figure 2 , this embodiment provides an easy-to-install, safe and reliable wall-out joint for buryable metal hoses, which includes a curved pipe body 10, and an external joint 11 is provided at one end of the curved pipe body 10 for accessing External equipment such as water heaters and stoves; the external joint 11 is fixed with a joint insert 30 with an internal thread. The stainless steel insert used in the joint insert 30 has an inner diameter greater than the diameter of the metal hose 60, which is convenient for the metal hose to connect. 60 installation, and at the same time, it is convenient to thread connection with external equipment to ensure the safety of sealing performance.

[0029] In this embodiment, the metal hose 60 uses a buryable stainless steel corrugated hose as a connecting pipe for transporting gas; The other end of the pipe body 10, that is, the other nozzle of the curved pipe body 10, is the hose access end for extending the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap