Method of using optical fiber Bragg grating to monitor temperature of intermediate connector of medium-voltage power cable

A technology for intermediate joints and power cables, applied in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve problems such as inaccurate measurement results, high current, and strong magnetic field effects, and achieve corrosion resistance and electromagnetic resistance Strong interference ability and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

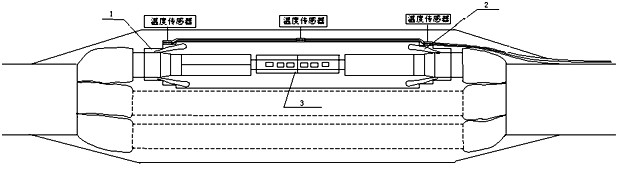

[0034] like figure 1 As shown: three optical fiber Bragg grating temperature sensors can be fixed on the outer surface of the cold-shrink insulation 1 through epoxy resin, and the fixing points correspond to the midpoint of the stress cone 2 at both ends and the midpoint of the intermediate connecting pipe 3 respectively. Then according to the change of the wavelength value reflected by the grating, the temperature of the stress cone at both ends of the joint and the temperature of the intermediate connecting pipe is calculated through the relationship between the shift of the fiber Bragg grating temperature sensor Bragg wavelength and the temperature; finally, according to the measured temperature and the conventional temperature In contrast, when any one or more of them is abnormal, it can be determined that the intermediate joint is in an abnormal working condition.

[0035] The selection of the fiber Bragg grating temperature sensor: common fiber Bragg grating temperature ...

Embodiment 2

[0037] In order to better realize the method, the present invention provides an optical fiber Bragg temperature sensor.

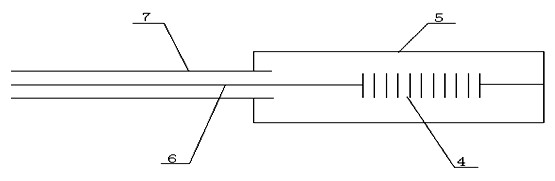

[0038] like figure 2 Shown: including fiber Bragg grating 4, capillary copper tube 5, polytetrafluoroethylene sleeve 6, fiber lead wire 7; use epoxy resin to tightly fix fiber Bragg grating 4 in capillary copper tube 5, fiber lead wire 7 strings In the polytetrafluoroethylene casing, the polytetrafluoroethylene casing 6 and the capillary copper tube 5 are connected as a whole through epoxy resin.

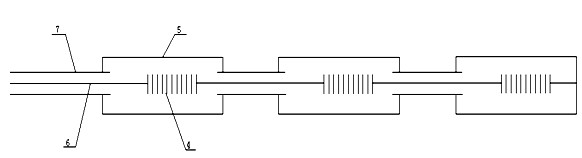

[0039] like image 3 As shown: the three optical fiber Bragg grating temperature sensors connected in series are connected in series and fixed on the outer surface of the cold-shrink insulation 1, and the fixing points correspond to the midpoint of the stress cone 2 at both ends and the intermediate connecting pipe respectively. The midpoint of 3; according to the change of the temperature of the three monitoring points to the wavelength of the grating, and th...

Embodiment 3

[0041] In order to realize described method better, the present invention improves above-mentioned optical fiber Bragg temperature sensor again, as Figure 4 As shown: it consists of fiber Bragg grating 4, capillary copper tube 5, polyimide sleeve 6, optical fiber lead wire 7, and annular metal sheet 8; fiber Bragg grating 4 is encapsulated in capillary copper tube 5 through epoxy resin , and the capillary copper tube 5 and the annular metal sheet 8 are integrally formed and connected as a whole, and the capillary copper tube 5 and the polyimide sleeve 6 sleeved on the optical fiber lead-out line 7 are sealed and connected by epoxy resin.

[0042]The annular metal sheet can be selected from steel, copper, etc., among which copper material with a large expansion coefficient (thermal expansion coefficient is 0.189×10-4m / °C) is preferred.

[0043] Three optical fiber Bragg grating temperature sensors connected in series are fixed on the outer surface of the cold-shrink insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com