Bifunctional direct current ice melting apparatus based on voltage source type current converter and ice melting method thereof

A voltage source type, DC ice-melting technology, applied in cable installation, output power conversion device, AC power input conversion to DC power output, etc., can solve the high reactive power demand of ice-melting power supply and the influence of system stability Large, difficult system power flow and other problems, to achieve the effect of reducing reactive power, improving power quality, and improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

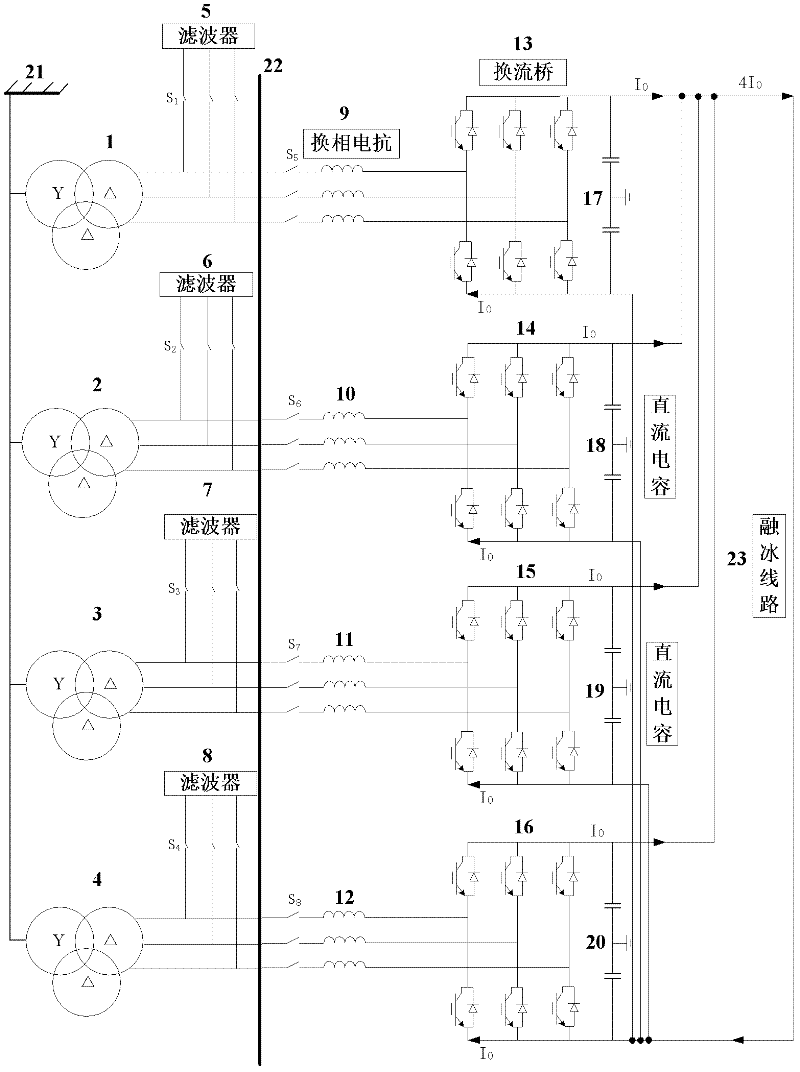

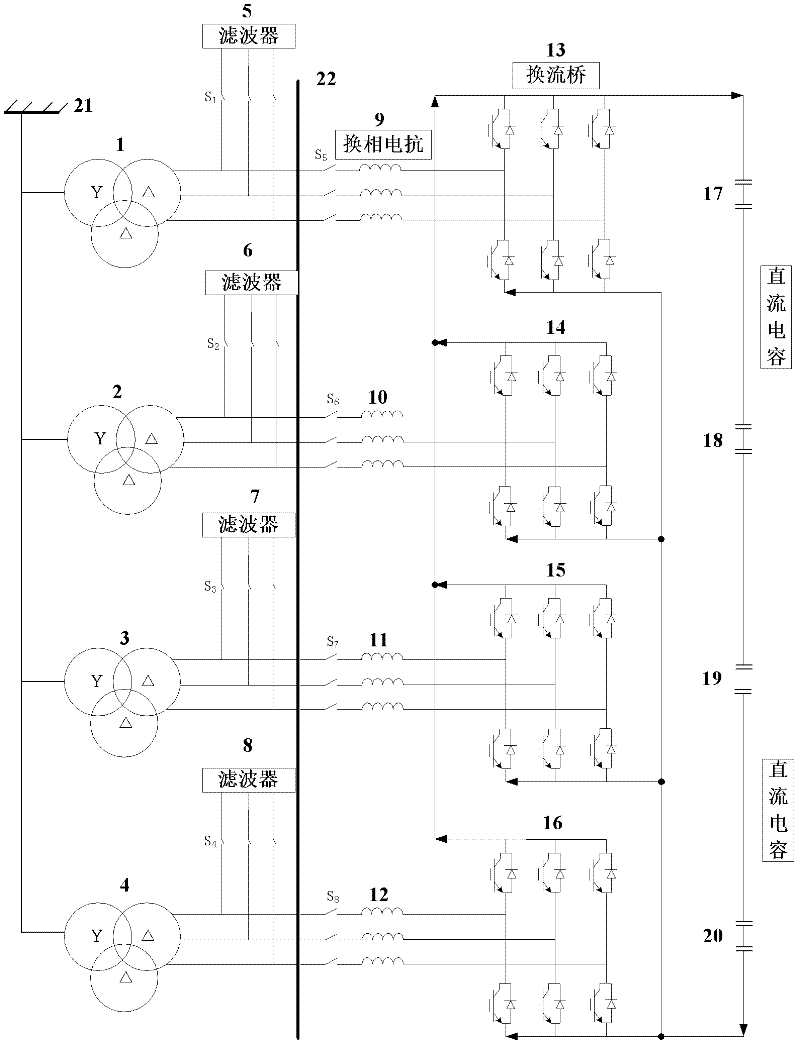

[0025] 1) Melting ice mode

[0026] In ice melting mode, the circuit topology is as follows figure 1 As shown, one side of the four groups of identical transformers 1-4 is connected to the AC system bus I 21, and the other side is connected to the bus II 22 of the ice-melting device to provide ice-melting power for the ice-melting device. Four groups of identical AC filters 5-8 are passed through four groups of switches S 1 -S 4 The same transformers 1-4 as the four groups are connected in parallel to the bus II22 to filter out the characteristic harmonics on the AC side of the system. Four groups of identical reactors 9-12 head ends pass through four groups of switches S 5 -S 8 It is connected in parallel to the busbar II 22, and the tail ends are respectively connected to the bridge arms of the voltage source type converter bridge 13-16. It is the link of energy exchange between the converter bridge and the AC side, and also plays a role in suppressing the rising speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com