Brush direct current motor speed regulation device with compensation feedback function and method therefor

A brushed DC motor, compensation feedback technology, applied in the direction of excitation or armature current control, can solve the problems of change, can not achieve closed-loop control, increase cost, etc., achieve the effect of simple control, improve efficiency and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments.

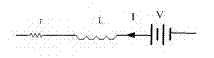

[0019] figure 1 Power supply for brushed DC motor and internal schematic diagram. It can be seen from the figure that the main electrical components of a brushed DC motor are composed of three parts: armature internal resistance R, inductance L and a voltage source V; voltage source V The power supply for the DC motor means the voltage applied to both ends of the motor, and the magnitude of the voltage determines the speed of the motor; L represents the magnetic field of the armature in the motor, which makes the motor rotate and do work, converting electrical energy into mechanical energy; the internal resistance of the armature R It is the internal resistance of the wire required to wind the motor coil. When the current I flows through the internal resistance R of the armature, a voltage drop will be generated and the power consumed will be converted into heat. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com