Method of using biogas slurry to treat continuous cropping obstacles of greenhouse soil

A soil continuous cropping obstacle and biogas slurry technology, applied in the fields of land preparation methods, applications, agricultural machinery and implements, can solve problems such as poor economy and poor operability, and achieve the goal of enhancing soil fertility, alleviating soil acidification, and eliminating continuous cropping obstacle factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

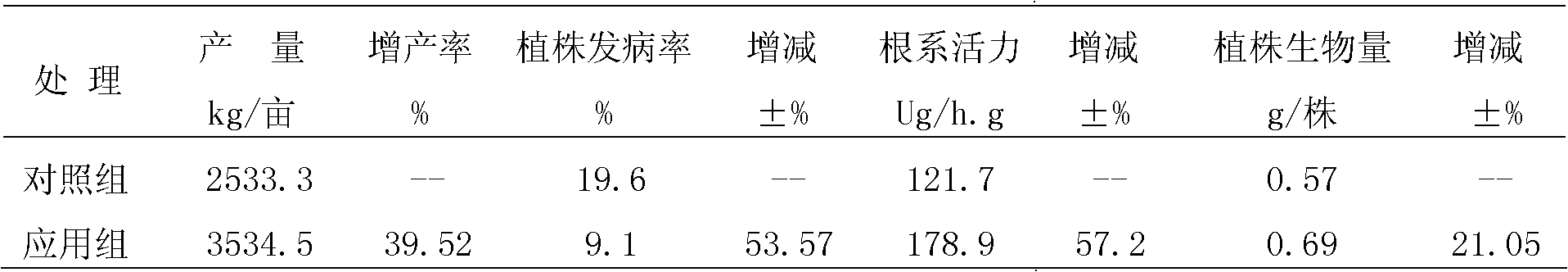

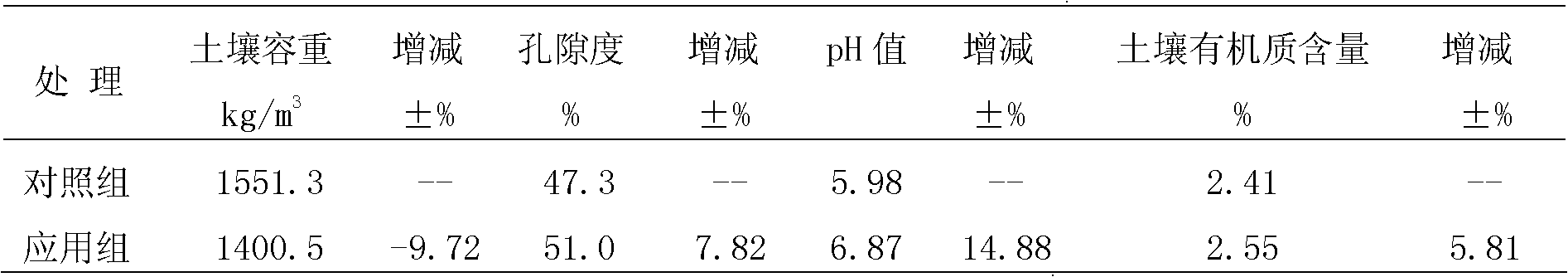

[0042] Example 1: Correction of soil continuous cropping obstacles in tomato greenhouses

[0043] (1) In the greenhouse where tomatoes have been planted continuously for 7 years, the soil continuous cropping obstacles are obvious. Choose the slack period of the greenhouse, and plant the whole row along the shed in the shed. The width of each row is 45 cm, and the two sides are ridges with a height of 15 cm and a width of 15 cm. The furrows are formed into slightly sloped troughs with a longitudinal slope of 4°, and covered with plastic film, including all ridges and furrows;

[0044] (2) The biogas slurry is taken from the biogas station of the normal centralized gas supply biogas project, and the biogas slurry is directly pumped from the anaerobic fermentation tank into the tanker and transported to the outside of the greenhouse.

[0045] (3) Place the biogas slurry outlet pipe directly under the intima membrane, adjust the biogas slurry flow rate so as not to wash up the so...

Embodiment 2

[0069] Example 2: Using biogas slurry to correct continuous cropping obstacles in Shouguang cucumber greenhouses, the steps are as follows:

[0070] In a greenhouse in Wamiao Village, Gucheng Township, Shouguang City, cucumbers have been continuously planted in the greenhouse for 9 years, and continuous cropping obstacles are obvious. Select 200m in the shed starting 9th July 2009 2 The plots are planted along the whole row, and the width of each row is 45cm, and the two sides are ridges with a height of 15cm and a width of 15cm. The furrows are formed into grooves with a slope of 4-7°, and ordinary mulch is used to cover the furrows. The biogas slurry was taken from 3 household biogas digesters with good fermentation in the local area. The biogas digesters were mainly composed of cow dung, rotten vegetable leaves, and human and animal manure. The shed and soil are plowed, and the application of basal fertilizer is the same as the customary fertilization of farmers. After t...

Embodiment 3

[0075] Example 3: Using biogas slurry to correct continuous cropping obstacles in Taian cucumber greenhouses, the steps are as follows:

[0076] The experiment was conducted in a greenhouse in Dagoutou Village, Shengzhuang Town, Tai’an City. Cucumbers had been continuously planted in the greenhouse for 7 years. Since the 5th year of planting, the continuous cropping obstacles in the greenhouse gradually became obvious. Production cuts were close to 50%. Selected 330m in the shed starting June 20, 2007 2 (10m×33m) plots, along the planting row, and the previous crop planting soil is placed at the bottom of the border. The width of each furrow is 45 cm, and both sides are ridges with a height of 15 cm and a width of 15 cm. The furrows are formed into grooves with a slope of 4-7°, and ordinary mulch is used to cover the furrows.

[0077] The biogas slurry is obtained from 3 household biogas digesters with good fermentation in the local area. The biogas digesters use cow dung a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com