Foam fire extinguisher

A technology of foam fire extinguishing and foam liquid, which is applied in fire rescue and other directions, can solve the problems of increasing environmental pollution and fire extinguishing costs, large amount of foaming agent used, and short spray distance, etc., to achieve cooling of the fire site, reduction of fire extinguishing costs, and export The effect of high momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

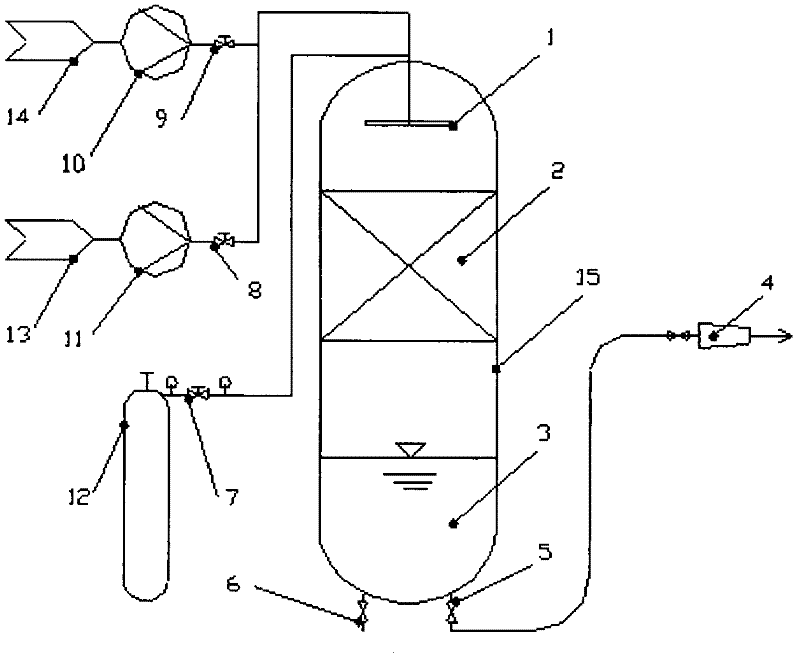

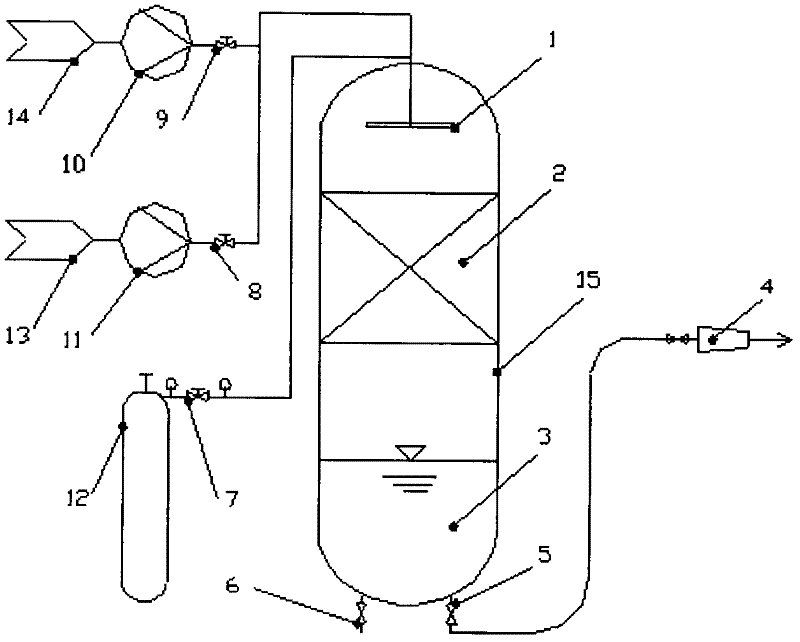

[0038] Commercially available 3% type fluoroprotein foam solution mixed with water at 1.5%, CO 2 Cylinder gas supply, such as figure 1 As shown, the ratio of the protein foam liquid to water is regulated by the water regulating valve (8) and the foam liquid regulating valve (9), and the gas regulating valve (7) regulates the pressure of the cylinder to 0.5MPa, CO 2 The gas flow rate: water flow rate is 3:1, and the ratio changes accordingly when the cylinder pressure is changed.

Embodiment 2

[0040] The commercially available 3% fluoroprotein foam liquid is mixed with 1.5% water, and the compressor supplies air, such as figure 1 As shown, the ratio of the protein foam liquid to water is adjusted through the water regulating valve (8) and the foam liquid regulating valve (9), the air supply pressure of the compressor is 0.5MPa, the air flow rate: the water flow rate is 1:20, and the ratio of the compressed air pressure is changed Change accordingly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap