Method for welding heterogeneous austenitic stainless steel plates

An austenitic stainless steel, welding method technology, applied in welding equipment, electron beam welding equipment, metal processing equipment and other directions, can solve the problem of low strength of nitrogen hole joints, reduce pore defects, improve joint strength, control welding deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

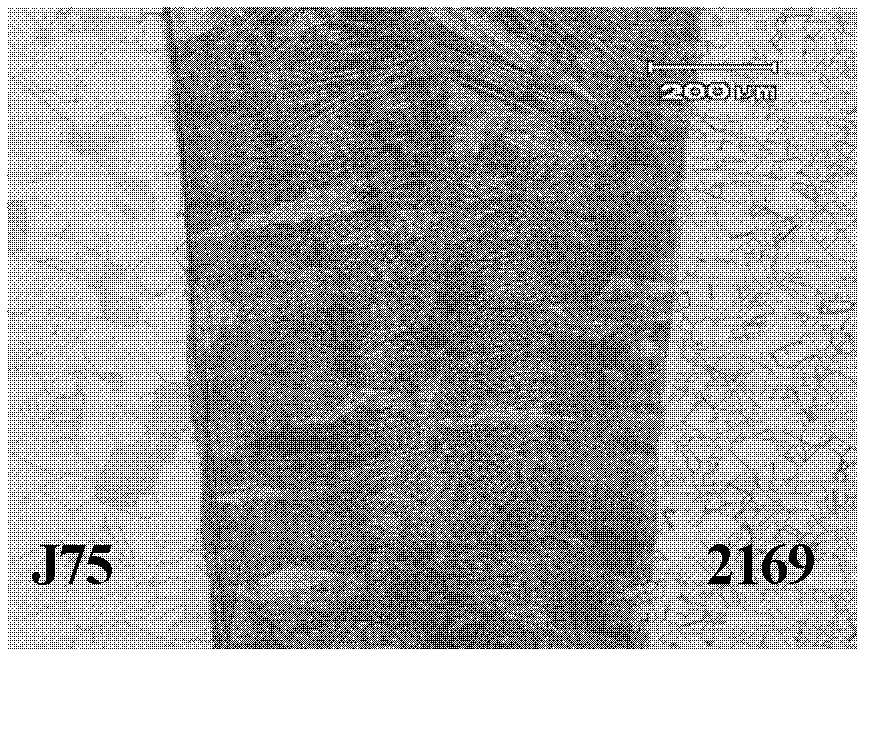

[0022] Embodiment 1: Vacuum electron beam welding of HR-2 stainless steel plate and J75 stainless steel plate of specification 220 (long) × 80 (wide) × 3.2mm (thick)

[0023] The specific implementation process is:

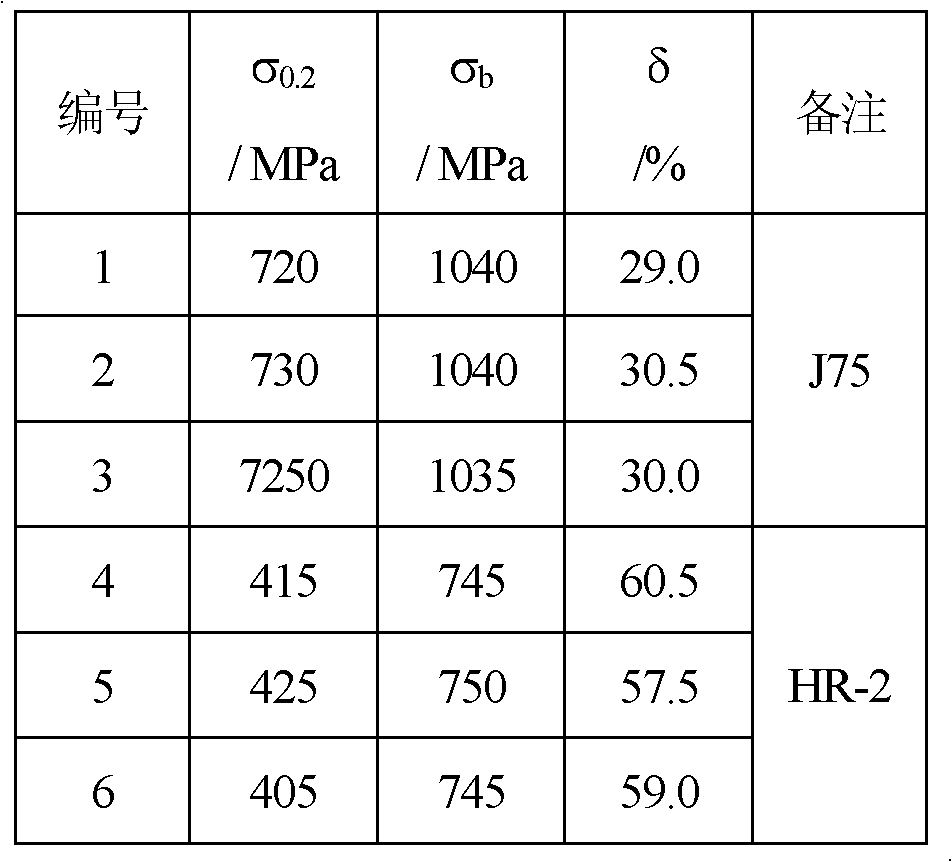

[0024] 1. Both HR-2 stainless steel plate and J75 stainless steel plate blanks are hot-rolled plates. The chemical composition and mechanical properties of the two hot-rolled plates meet the requirements of GJB 5724-2006 "Specification for Hydrogen-resistant Steel Bars". The HR-2 plate was subjected to 1050°C / 1h, water quenching treatment, and the J75 plate was subjected to 980°C / 1h, water quenching +740°C / 8h, and air cooling treatment. The mechanical properties of the two stainless steel plates are shown in Table 1. The plate after heat treatment is machined to 2.0-5.0 mm (3.2 mm in this embodiment), and the length direction is machined to roughness Ra1.0 μm by grinding machine.

[0025] 2. Carry out decontamination treatment on the base metal after polishing tr...

Embodiment 2

[0038] Embodiment 2: Vacuum electron beam welding of HR-2 stainless steel plate and J75 stainless steel plate of specification 220 (length) × 80 (width) × 4.5mm (thick)

[0039] The difference from Example 1 is that the thickness of the welded J75 and HR-2 plates is both 4.5mm, and the welding process parameters and the number of electron beam scanning after welding are adjusted accordingly.

[0040] The same heat-treated HR-2 stainless steel plate and J75 stainless steel plate blanks as in Example 1 were used, machined to a thickness of 4.5 mm after heat treatment, and processed to a roughness of Ra1.2 μm by a grinder in the length direction; petroleum ether was used 20 minutes before welding Degrease, and scrub the polished base metal with alcohol; then clamp and fix the HR-2 stainless steel plate and J75 stainless steel in the welding room by means of butt joint and tight fit, and keep the two base metals placed horizontally; close the vacuum welding room And pump the vacuu...

Embodiment 3

[0044] Embodiment 3: Vacuum electron beam welding of HR-2 stainless steel plate and J75 stainless steel plate of specification 220 (long) × 80 (wide) × 2.5mm (thick)

[0045] The difference from Example 1 is that the thickness of the welded J75 and HR-2 plates is both 2.5 mm, and the welding process parameters and the number of electron beam scanning after welding are adjusted accordingly.

[0046] The same heat-treated HR-2 stainless steel plate and J75 stainless steel plate blanks as in Example 1 were used, machined to a thickness of 2.5 mm after heat treatment, and processed to a roughness of Ra1.2 μm by a grinder in the length direction; petroleum ether was used 10 minutes before welding Degrease, and scrub the polished base metal with alcohol; then clamp and fix the HR-2 stainless steel plate and J75 stainless steel in the welding room by means of butt joint and tight fit, and keep the two base metals placed horizontally; close the vacuum welding room And pump the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com