Organic fertilizer and preparation method thereof

An organic fertilizer and fertilizer technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as soil compaction, and achieve the effect of preventing and controlling diseases and insect pests with low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

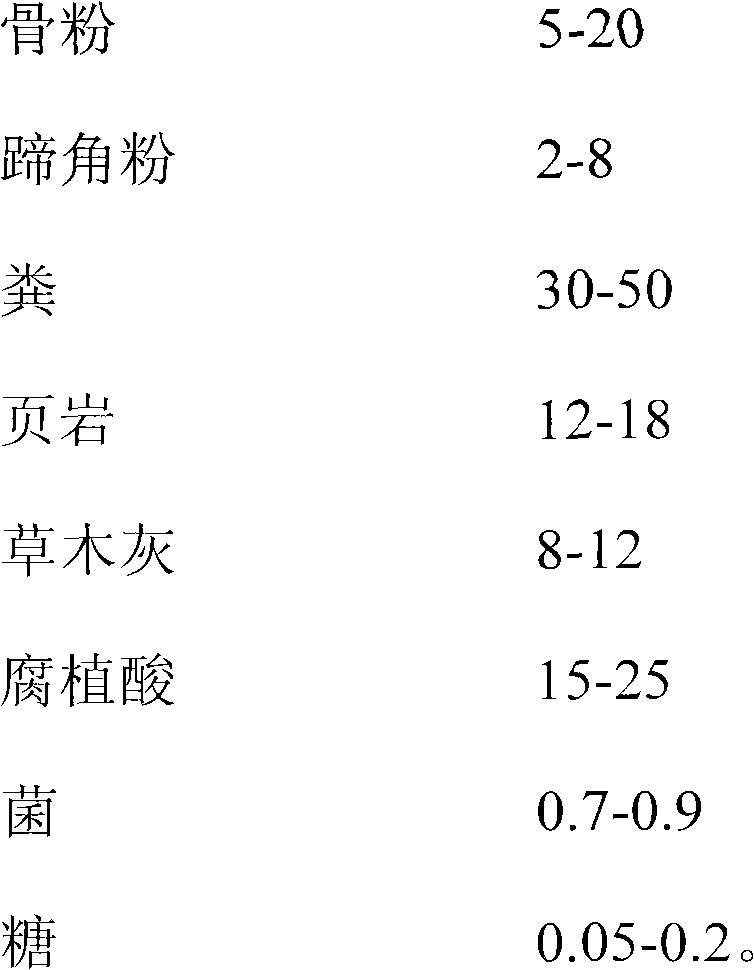

Method used

Image

Examples

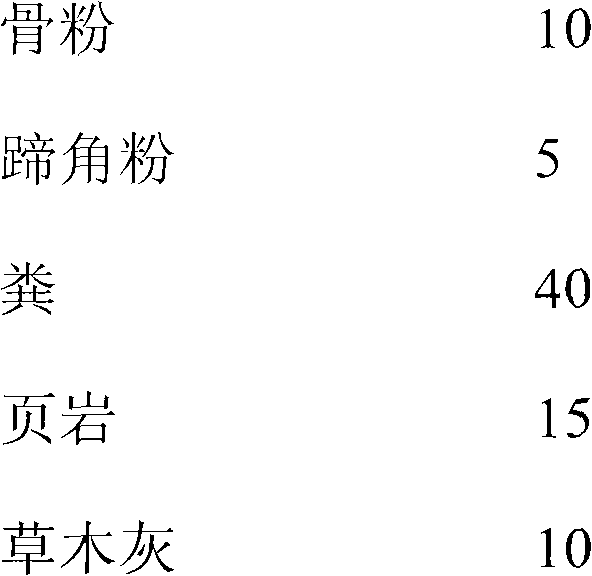

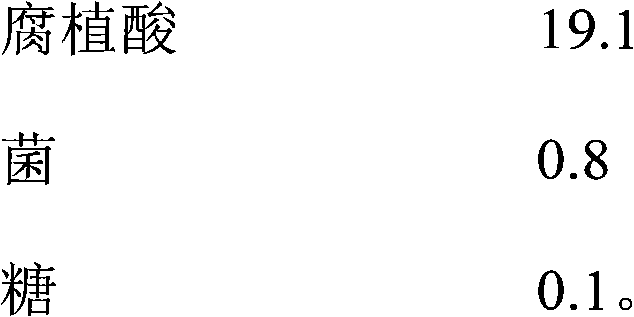

Embodiment 1

[0039]The raw materials are mixed according to the following weight ratio: bone powder 10, hoof horn powder 5, manure 40, shale 15, plant ash 10, humic acid 19.1, bacteria 0.8, sugar 0.1. The preparation method of the product of the present invention is as follows: prepare the raw materials according to the above-mentioned ratio, mix them, and ferment for two weeks at 45 degrees Celsius. It is enough to see the white silk mesh produced by fermentation. After drying, it can be crushed into granules, and the moisture It is 10-15%, promptly obtains the product of the present invention.

Embodiment 2

[0041] The raw materials are mixed according to the following weight ratio: bone powder 5, hoof horn powder 2, dung 30, shale 12, plant ash 8, humic acid 15, bacteria 0.7, sugar 0.05. The preparation method of the product of the present invention is as follows: prepare the raw materials according to the above-mentioned ratio, mix them, and ferment for a week at 70 degrees Celsius. It is enough to see the white silk mesh produced by fermentation, and it can be pulverized into granules after drying, and the water content is 10-15%, promptly obtains the product of the present invention.

Embodiment 3

[0043] The raw materials are mixed according to the following weight ratio: bone powder 20, hoof horn powder 8, dung 50, shale 18, plant ash 12, humic acid 25, bacteria 0.9, sugar 0.2. The preparation method of the product of the present invention is as follows: prepare the raw materials according to the above-mentioned proportions, mix them, and ferment for 12 days at 55 degrees Celsius. It is enough to see the white silk mesh produced by fermentation. After airing, it can be crushed into granules, and the moisture It is 10-15%, promptly obtains the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com