Cement grinding aid reinforcing agent and preparation method thereof

A grinding aid and cement technology, which is applied in the field of cement admixtures, can solve the problems of unstable performance, high price and high cost of cement grinding aid enhancer, and achieves obvious grinding aid enhancement effect and stable performance. , the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of a cement grinding aid enhancer, comprising the following steps:

[0031] Step a) under the action of a catalyst, the addition reaction of urea and the first formaldehyde in water;

[0032] Step b) performing a condensation reaction on the reaction product of the addition reaction, sodium p-aminobenzenesulfonate and second formaldehyde to obtain a cement grinding aid enhancer.

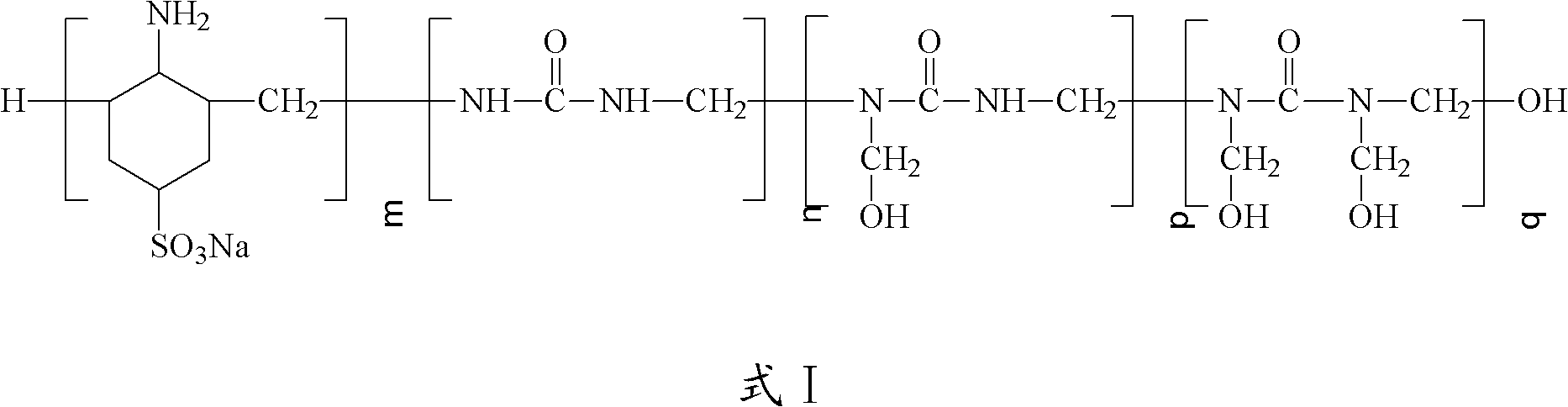

[0033] In the above-mentioned preparation process, the present invention first utilizes the addition reaction of urea and formaldehyde to prepare methylol urea with a grinding-aiding and strengthening effect having a molecular structure similar to triethanolamine, and then combines methylol urea, formaldehyde, and Sodium p-aminobenzenesulfonate was subjected to polycondensation reaction to prepare a macromolecular substance with grinding aid enhancement effect.

[0034] The step a) specifically includes: step a1) adding urea and water into the reac...

Embodiment 1

[0047] (1) Add 60g of urea and 60g of water into the reaction flask, stir until the urea is dissolved, then add 10g of sodium hydroxide; raise the temperature of the system to 50°C, add 100g of formaldehyde solution dropwise within 1h, and continue the reaction for 1h;

[0048] (2) Add 50g of sodium p-aminobenzenesulfonate to the reaction flask, continue to stir and keep the above temperature constant, start to add the remaining 65g of formaldehyde solution dropwise, and keep adding dropwise within 2 hours;

[0049] (3) The temperature of the reaction system was raised to 75° C., and the reaction was maintained for 3 hours; then the temperature was lowered and the material was discharged to obtain a light red liquid, that is, a cement grinding aid enhancer.

Embodiment 2

[0051] (1) Add 70g of urea and 70g of water into the reaction flask, stir until the urea is dissolved, then add 15g of potassium hydroxide; raise the temperature of the system to 55°C, add 182g of formaldehyde solution dropwise within 2h, and continue the reaction for 1h;

[0052] (2) Add 50g of sodium p-aminobenzenesulfonate to the reaction flask, continue to stir and keep the above temperature constant, start to add the remaining 78g of formaldehyde solution dropwise, and keep adding dropwise within 2.5 hours;

[0053] (3) The temperature of the reaction system was raised to 80° C., and the reaction was maintained for 4 hours; then the temperature was lowered and the material was discharged to obtain a light red liquid, that is, a cement grinding aid enhancer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com