Carboxymethyl chitosan oligosaccharide quaternary ammonium salt/rectorite nanometer composite material and preparation method and application thereof

A technology of carboxymethyl chitosan oligosaccharide and nano-composite material, which is applied in the field of daily cosmetics and cosmetic additives, can solve the problems of high price of hyaluronic acid, zero physiological activity, and promote carcinogenesis, and achieves good UV resistance and anti-cancer properties. Oxidative, good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

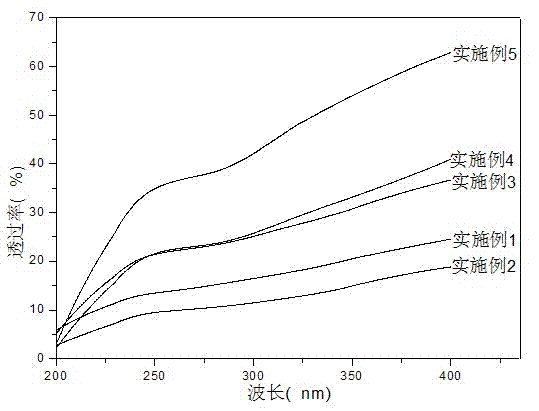

Examples

Embodiment 1

[0023] In the carboxymethyl chitooligosaccharide quaternary ammonium salt / rectorite nanocomposite material in this example, the carboxymethyl chitooligosaccharide quaternary ammonium salt accounted for 33.33%, and the rectorite accounted for 66.67%.

[0024] The weight average molecular weight of above-mentioned carboxymethyl chitosan oligosaccharide quaternary ammonium salt is 2.0 * 10 4 , the carboxymethyl substitution degree is 95%, and the substitution degree of the quaternary ammonium group is 20%.

[0025] The preparation method of the above-mentioned exfoliated carboxymethyl chitosan oligosaccharide quaternary ammonium salt / rectorite nanocomposite material is as follows:

[0026] step 1.

[0027] Disperse rectorite in deionized water to form a suspension with a concentration of 15 mg / mL, and obtain a rectorite suspension after swelling at room temperature for 36 hours;

[0028] Carboxymethyl chitosan quaternary ammonium salt was dissolved in deionized water to prepare...

Embodiment 2

[0032] In the carboxymethyl chitooligosaccharide quaternary ammonium salt / rectorite nanocomposite material in this embodiment, the carboxymethyl chitooligosaccharide quaternary ammonium salt accounts for 50%, and the rectorite accounts for 50%.

[0033] The weight average molecular weight of above-mentioned carboxymethyl chitosan oligosaccharide quaternary ammonium salt is 1.3 * 10 4 , the carboxymethyl substitution degree is 80%, and the substitution degree of the quaternary ammonium group is 35%.

[0034] The preparation method of the above-mentioned exfoliated carboxymethyl chitosan oligosaccharide quaternary ammonium salt / rectorite nanocomposite material is as follows:

[0035] step 1.

[0036] Disperse rectorite in deionized water to form a suspension with a concentration of 10 mg / mL, and obtain a rectorite suspension after swelling at room temperature for 30 hours;

[0037] Carboxymethyl chitosan quaternary ammonium salt was dissolved in deionized water to prepare a co...

Embodiment 3

[0041] In the carboxymethyl chitooligosaccharide quaternary ammonium salt / rectorite nanocomposite material in this example, the carboxymethyl chitooligosaccharide quaternary ammonium salt accounted for 66.67%, and the rectorite accounted for 33.33%.

[0042] The weight average molecular weight of above-mentioned carboxymethyl chitosan oligosaccharide quaternary ammonium salt is 8.0 * 10 3 , the carboxymethyl substitution degree is 50%, and the substitution degree of the quaternary ammonium group is 55%.

[0043] The preparation method of the above-mentioned exfoliated carboxymethyl chitosan oligosaccharide quaternary ammonium salt / rectorite nanocomposite material is as follows:

[0044] step 1.

[0045] Disperse rectorite in deionized water to form a suspension with a concentration of 10 mg / mL, and obtain a rectorite suspension after swelling at room temperature for 24 hours;

[0046] Carboxymethyl chitosan quaternary ammonium salt was dissolved in deionized water to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com