Hair slip prevention finishing agent and finishing method for rabbit hair fabric

A technology of anti-hair loss and finishing agent, which is applied in the treatment of textile materials, fiber treatment, animal fibers, etc., can solve the problem of poor washing resistance of rabbit fur fabrics, restricting the development of rabbit fur textile industry, and increasing the amount of hair shedding of rabbit fur fabrics And other problems, to achieve the effect of good effect, low cost, soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the resin finishing solution is as follows: according to the mass percentage composition of the resin finishing solution, under the condition of mechanical stirring and emulsifier OP-10, first mix water-based polyurethane, water-based blocked group isocyanate and water-based acrylic resin with mixed with water to form a homogeneous mixed solution; then the pH value of the mixed solution was adjusted to 7-8 with the regulator sodium bicarbonate or sodium carbonate to obtain the resin finishing solution;

[0038] (2) The mass percent of the finishing solution for improving the hand feeling consists of:

[0039] Amino silicone oil softener 5-25%,

[0040] The balance is water, and the sum of each component is 100%;

[0041] The preparation method of the hand-improving finishing liquid is as follows: according to the mass percentage composition of the hand-improving finishing liquid, the amino silicone oil softener and water are mixed and stirred ...

Embodiment 1

[0085] The one-step finishing process was used to prevent hair loss on the pure rabbit hair knitted sweater, and the weight of the knitted sweater was 300g.

[0086] 1. Composition and preparation of anti-lint finishing working solution:

[0087] (1) Mass percent composition and preparation of resin finishing liquid:

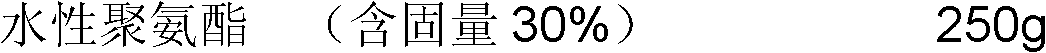

[0088]

[0089]

[0090] First mix the water-based polyurethane, water-based blocked group isocyanate and water in the stated proportion to make a uniform mixture; then mix the stated proportion of water-based polyacrylic acid and emulsifier OP-10 evenly, and slowly add Into the uniform mixture of water-based polyurethane, water-based blocked isocyanate and water, then continue to stir, and add penetrant JFC and crosslinking agent triethanolamine, and finally add sodium bicarbonate, adjust the pH value of the mixture to 7, and stir Evenly, the resin finishing working solution is obtained.

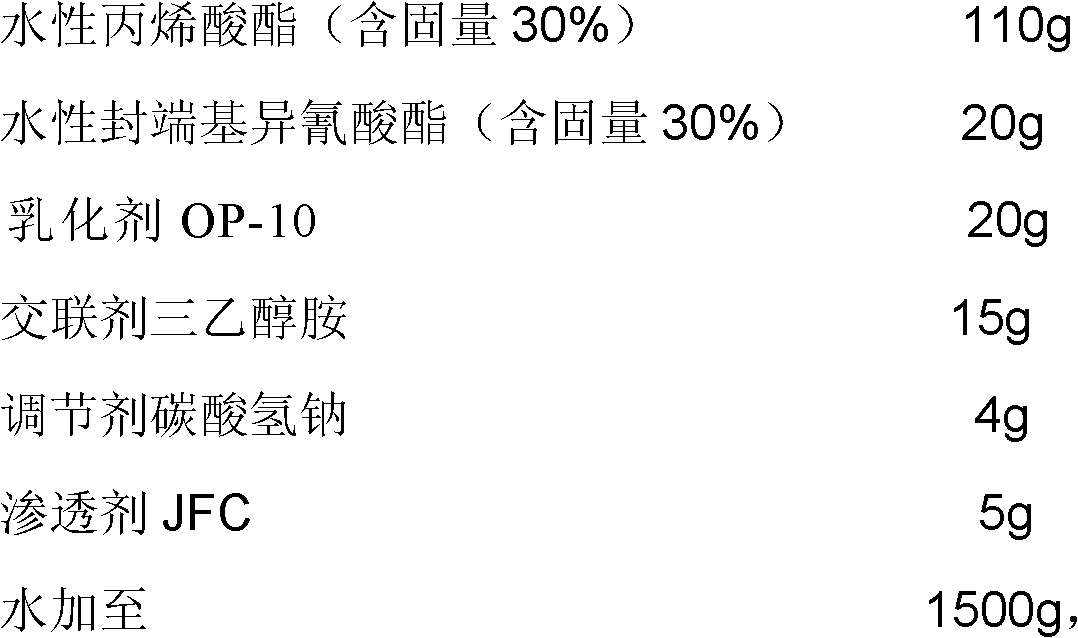

[0091] (2) The composition and preparation of the mass percentag...

Embodiment 2

[0116] A step-by-step finishing process was used to prevent shedding of the pure rabbit fur knitted scarf. The scarf weighed 180g.

[0117] 1. Mass percentage composition and preparation of the anti-lint finishing working solution:

[0118] (1) Composition and preparation of resin finishing solution:

[0119]

[0120] Mix the water-based polyurethane, water-based blocked group isocyanate and water in the stated proportion to make a uniform mixture; then mix the stated proportion of water-based polyacrylic acid and emulsifier OP-10 evenly, and slowly add it to the water-based In the mixed solution of polyurethane, water-based blocked group isocyanate and water, then continue to stir, and add penetrating agent JFC and crosslinking agent triethanolamine, finally add sodium bicarbonate, adjust the pH value of the mixed solution to 7, and stir evenly, that is Get the resin finishing working solution.

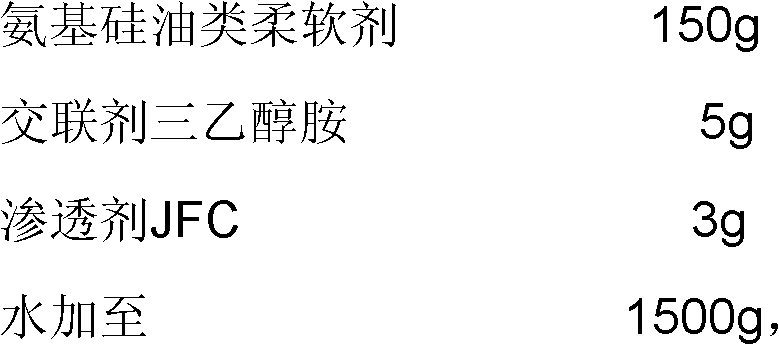

[0121] (2) The composition and preparation of the mass percentage of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com