Rotary demodulation type multi-mode high-efficiency microscanner

A technology of rotary modulation and micro-scanner, applied in the field of micro-scanning imaging, can solve the problem of no substantial improvement in the transfer letter, and achieve the effect of high practical value and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

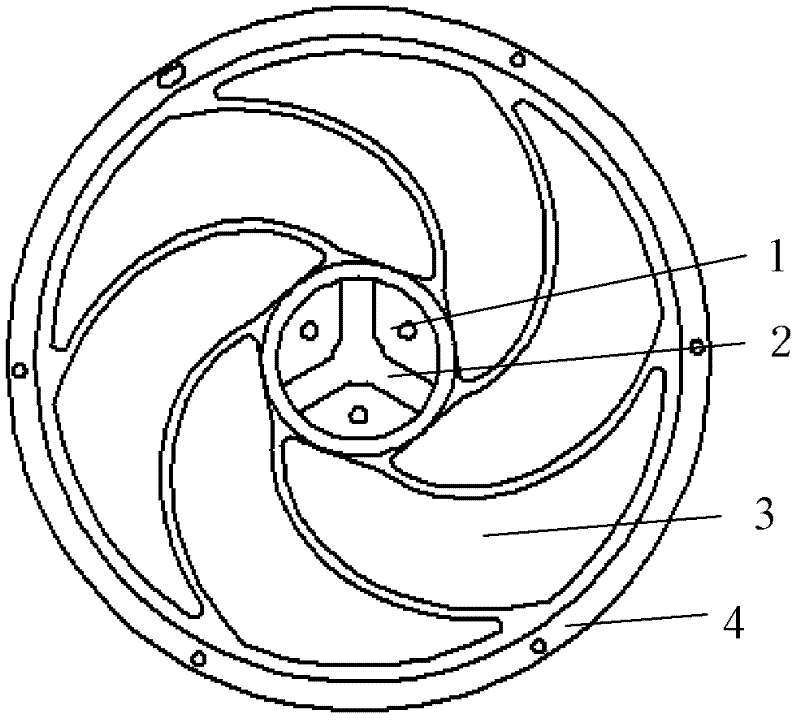

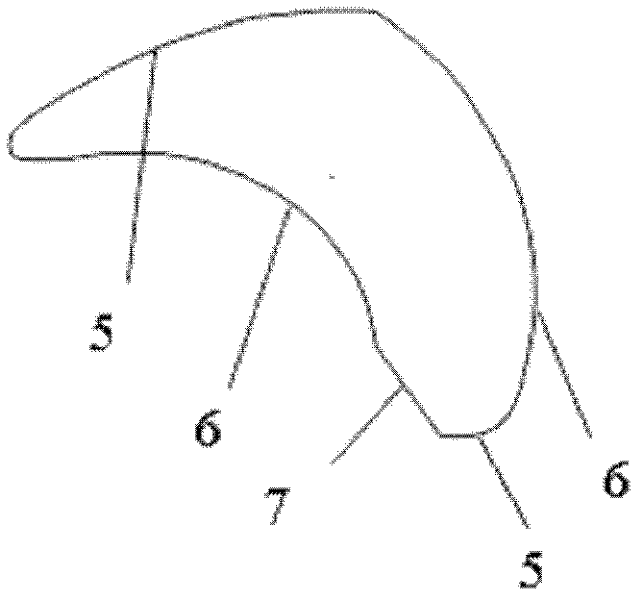

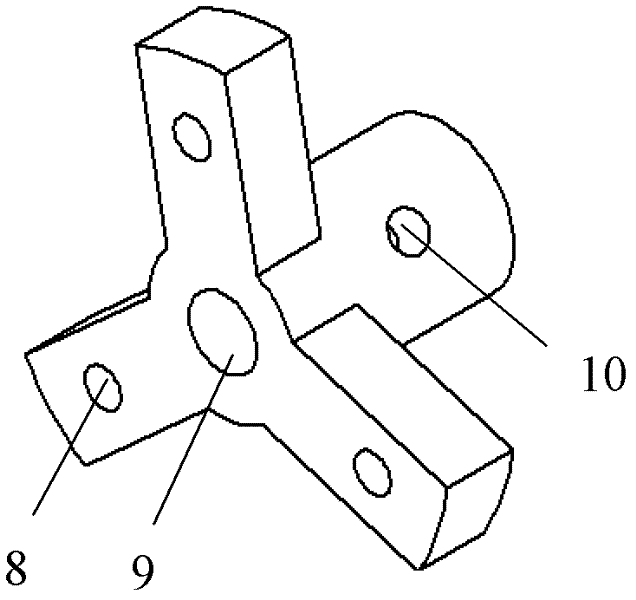

[0025] The rotary modulation type multi-mode high-efficiency microscanner is mainly composed of a rotating disk 17 containing flat optical elements, a fixed plate 15, a coupling 16, a photocoupler 12 for generating synchronous signals, a servo motor 19 and its drive circuit 18, etc. Such as figure 1 As shown, the rotating disk is roughly divided into three parts: the inner zone, the middle zone and the outer zone. There is a flange 1 connected to the servo motor 19 in the inner area, and three rectangular through holes 2 at 120° are arranged on the flange for use when the coupling 16 is assembled; the middle area is the area for installing flat plate components, and the area is divided into A number of windows 3 consistent with the shape of the flat element, with narrow support strips between the windows; the outer area is the edge area, the thickness is smaller than that of the middle area, and there is a small hole 4 for synchronous signal generation on it, and each window o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com